EAMM-A-T...-...A/P/R-15

Axial kit

Festo SE & Co. KG

Ruiter Straße 82

73734 Esslingen

Deutschland

+49 711 347-0

www.festo.com

Assembly instructions

8169507

2022-03f

[8169509]

Translation of the original instructions

© 2022 all rights reserved to Festo SE & Co. KG

1Applicable documents

All available documents for the product è www.festo.com/sp.

Document Product

Operating instructions Motor

Operating instructions Axis

Tab. 1: Applicable documents

2 Safety

2.1 Safety instructions

–Only mount the product on components that are in a condition to be safely

operated.

–Clean the shafts. The coupling hubs [1] grip without slipping only on dry and

grease-free shaft journals.

–Maintain the proper alignment of the coupling hubs [1].

–Support the combination in the following cases:

–If there are protruding or heavy motor attachments.

–In the event of severe vibrations, vibration loads or shock loads.

–If the motor is loosened or turned, homing must be carried out on the axis.

–Select required mounting components. The kit contains all the mounting com-

ponents that may be required.

–Observe the tightening torques. Unless otherwise specified, the tolerance is

± 20%.

2.2 Intended use

2.2.1 Use

The axial kit connects an axis to a motor configured axially to the driven shaft.

2.2.2 Permissible axes and motors

NOTICE

Overloading can cause malfunction and material damage.

The motor’s output variables must not exceed the permissible values of the

components used.

Permissible values è www.festo.com/catalogue.

• Limit the motor’s output variables accordingly.

• Take the axis and the motor from the interface codes.

Example: EAMM-A-T42-60P

T42: axis interface

60P: motor interface

Axis interface Axis

T42 EGSC-BS-60, ELGC-BS-60, ELGC-TB-60,

EPCC-BS-60

T46 ELGC-BS-80, ELGC-TB-80, ELGT-BS-90,

ELGT-BS-120, ELGT-BS-160

Tab. 2: Permissible axes

Motor interface Motor

55A EMMS-AS-55, third-party motor

57A EMCS-/EMMS-ST-57, third-party motor

58AA Third-party motor

60AA Third-party motor

60AB Third-party motor

Motor interface Motor

60P EMMB-/EMME-/EMMT-AS-60, third-party motor

60PA Third-party motor

60R Third-party motor

60RA Third-party motor

67A EMCA-EC-67

70A EMMS-AS-70, third-party motor

70AA Third-party motor

80P EMMB-/EMME-/EMMT-AS-80, third-party motor

80PA Third-party motor

80PB Third-party motor

85AA Third-party motor

87A EMMS-ST-87

100A EMME-/EMMS-/EMMT-AS-100, third-party

motor

Tab. 3: Permissible motors

It is the responsibility of users to qualify third-party motors with the matching

mechanical interface for the combination.

To find out which third-party motors are suitable, consult your regional Festo

contact or è www.festo.com/sp.

2.3 Training of qualified personnel

Work on the product may only be carried out by qualified personnel who can eval-

uate the work and detect dangers. Personnel must have the relevant mechanical

training.

3 Additional information

–Contact the regional Festo contact if you have technical problems.

–Accessories è www.festo.com/catalogue.

4 Scope of delivery

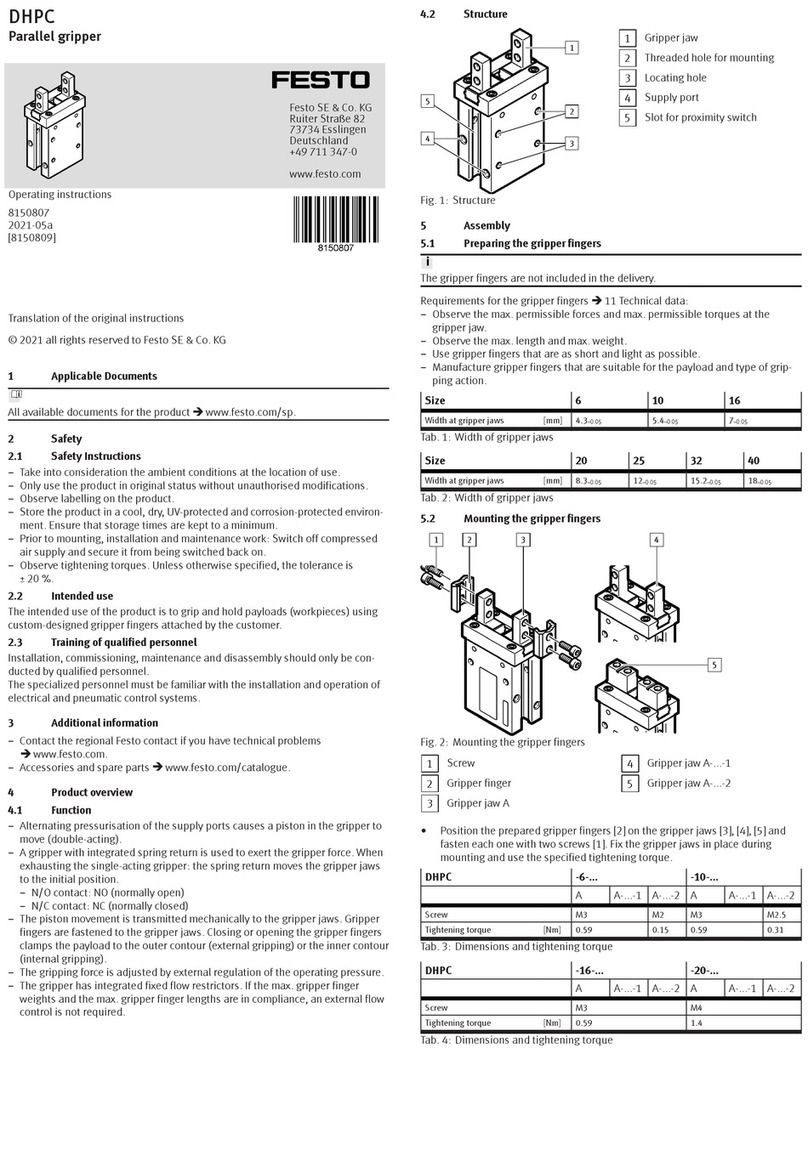

Fig. 1: Basic scope of delivery

1Coupling hub (1x)

2Locking screw (1x)

5Coupling housing (1x)

7Screw (4x)

10 Screw (4x)

19 Elastomer spider (1x)

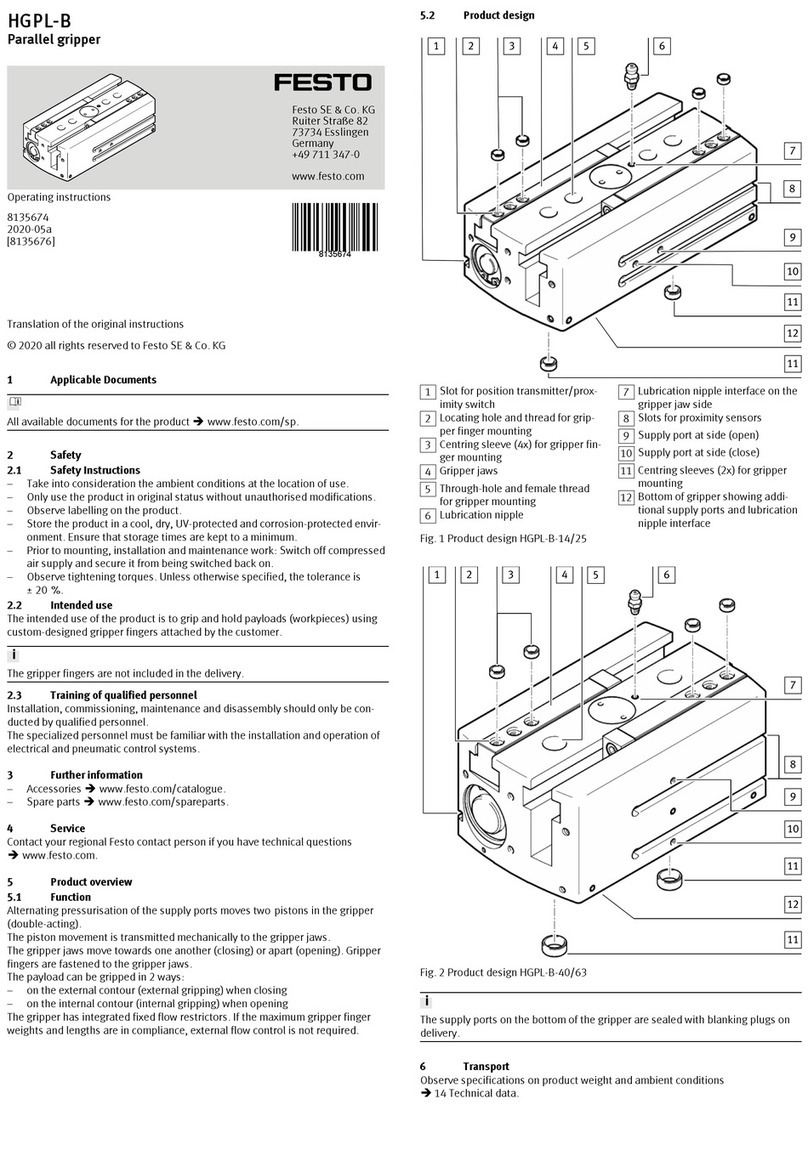

Fig. 2: Supplement to reducing sleeve

Reducing sleeve (4x)

5 Assembly

5.1 Assembly

5.1.1 Preassembly of reducing sleeve

The reducing sleeves [30] are only required if the mounting holes on the output

flange of the motor are too large for the supplied retaining screws.

Fig. 3: Insert reducing sleeves

•Insert reducing sleeves [30] into the mounting holes of the motor.