Translation of the original instructions

© 2020 all rights reserved to Festo SE & Co. KG

1 About this document

1.1 Applicable Documents

All available documents for the product èwww.festo.com/sp.

2 Safety

2.1 Safety instructions

– The product may only be used in its original status without unauthorised

modifications.

– Only use the product if it is in perfect technical condition.

– Use the product only inside buildings.

– Take into consideration the ambient conditions at the location of use.

– The product is intended for use in industrial environments. This product can

generate high frequency malfunctions, which may make it necessary to imple

ment interference suppression measures in residential areas.

– Observe the specifications on the product labelling.

– Comply with all applicable national and international regulations.

– Observe the local regulations for environmentally friendly disposal.

2.2 Intended Use

The intended use of the gripper kit for robots is for integration into the UR soft

ware and hardware connection for handling tasks of payloads.

Use the product only as follows:

– Within the limits of the product defined by the technical data

– In the industrial sector, in research laboratories, in assembly areas, in series

and special machines

– Permanently mounted

2.3 Training of Qualified Personnel

Installation, commissioning, maintenance and disassembly should only be con

ducted by qualified personnel.

The specialized personnel must be familiar with the installation and operation of

electrical and pneumatic control systems.

3 Further information

– Accessories èwww.festo.com/catalogue.

– Spare parts èwww.festo.com/spareparts.

4 Service

Contact your regional Festo contact person if you have technical questions

èwww.festo.com.

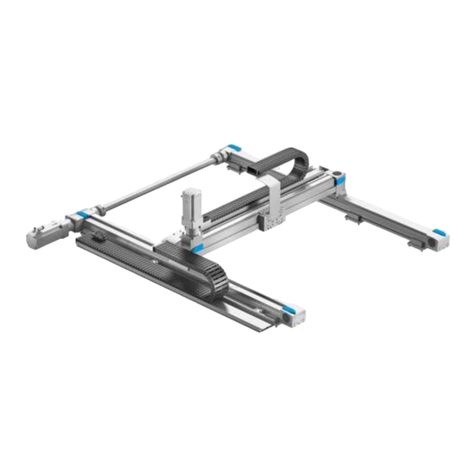

5 Design

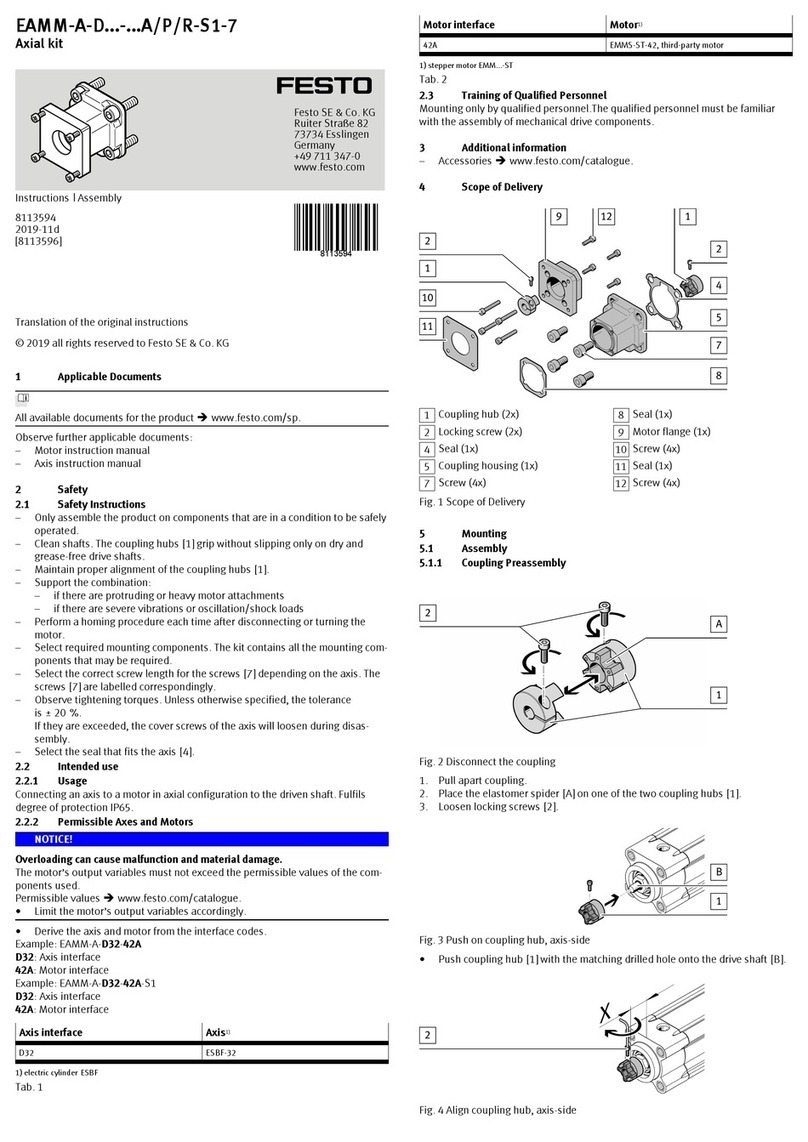

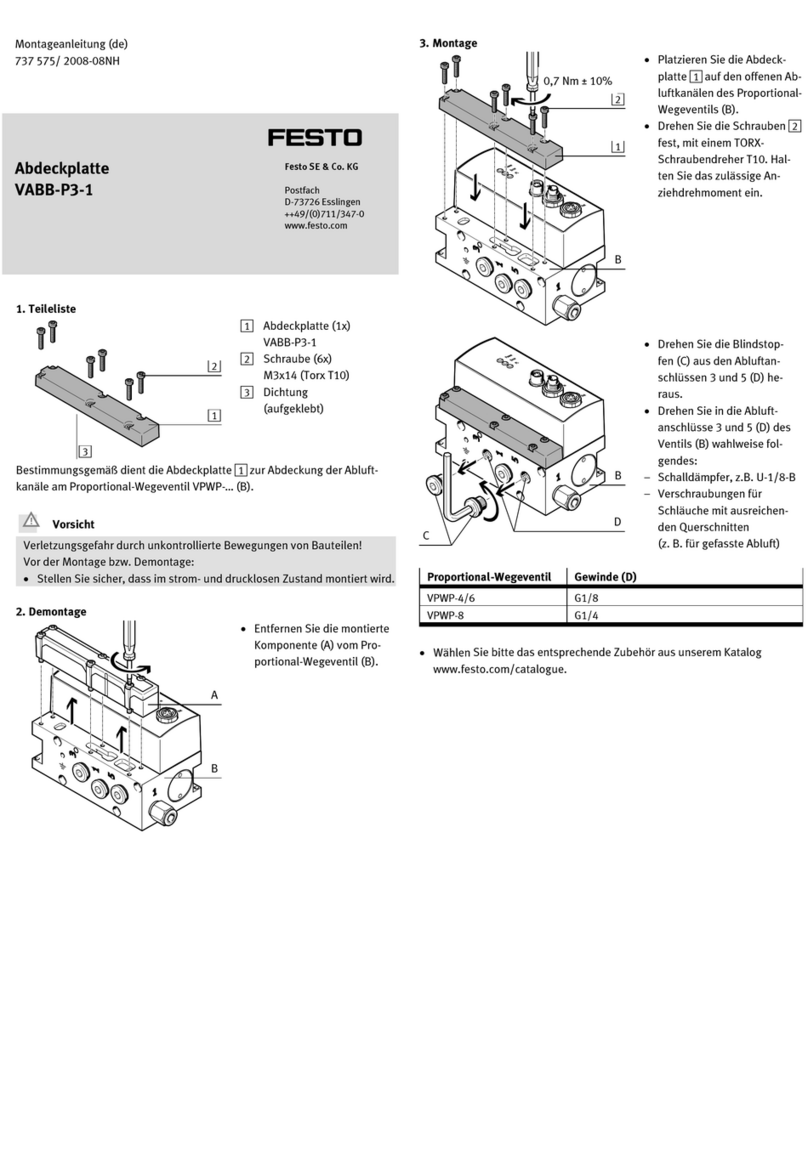

1Robot flange

2Adapter plate

3Alternative vacuum connection

with blanking plug (4x)

4Socket head screw M6 (4x)

5Blanking plug for vacuum connec

tion

6Suction cup with connection

7Distance piece

8Vacuum generator

9Velcro strap (2 m)

10 USB memory stick

11 Connecting cable (2x)

12 Socket head screws M4 (2x)

Fig. 1 Parts overview

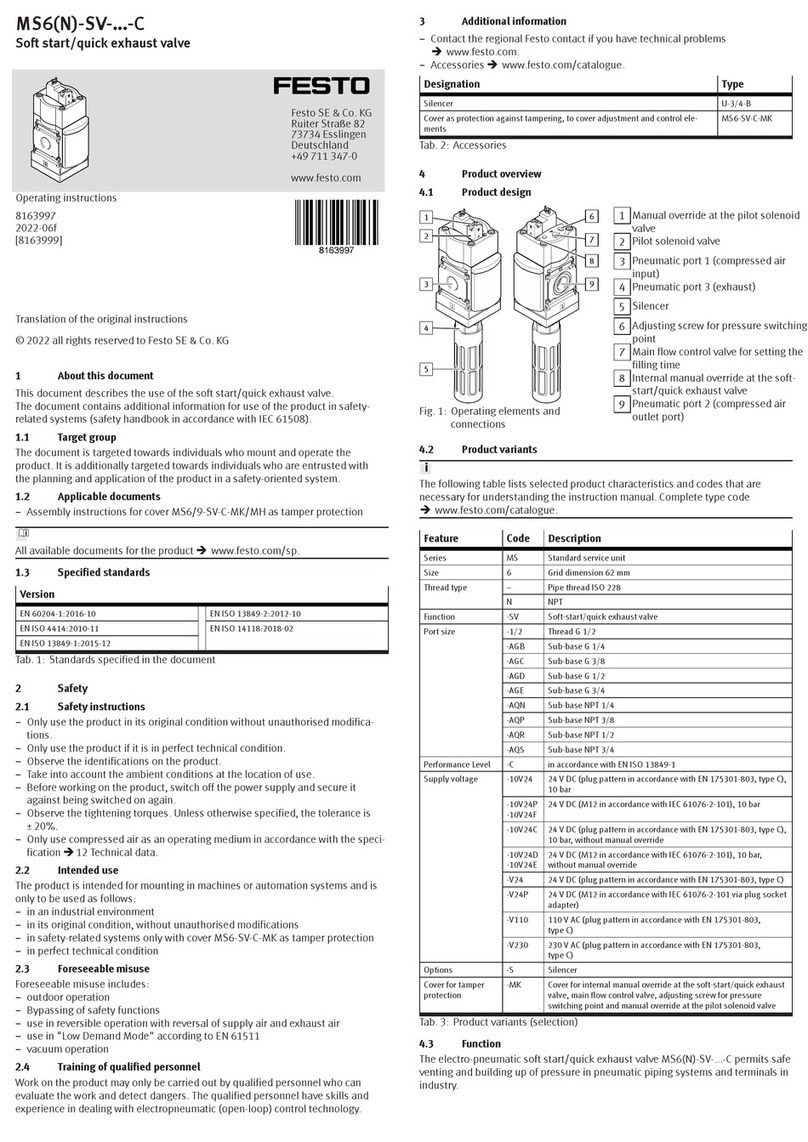

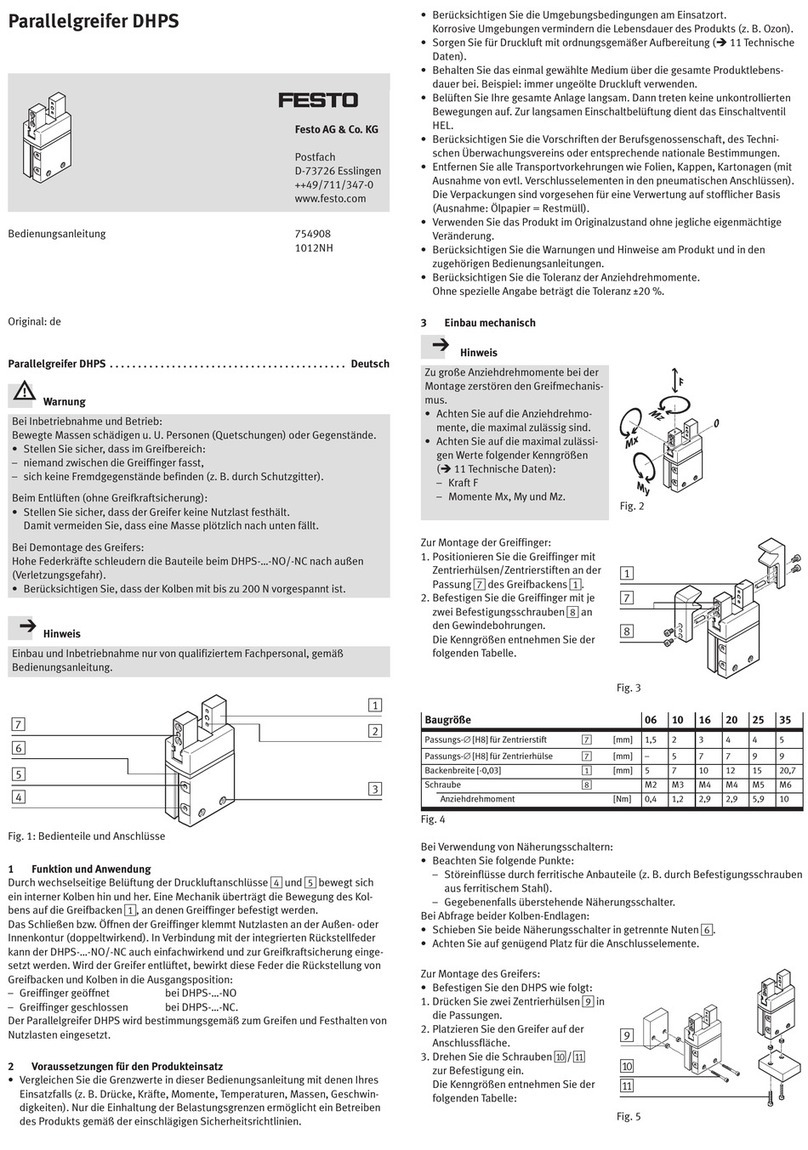

13 Vacuum sensor connection

14 Connection for solenoid valve,

ejector pulse

15 Solenoid valve vacuum connec

tion

16 Vacuum port

Fig. 2 Structure OVEL

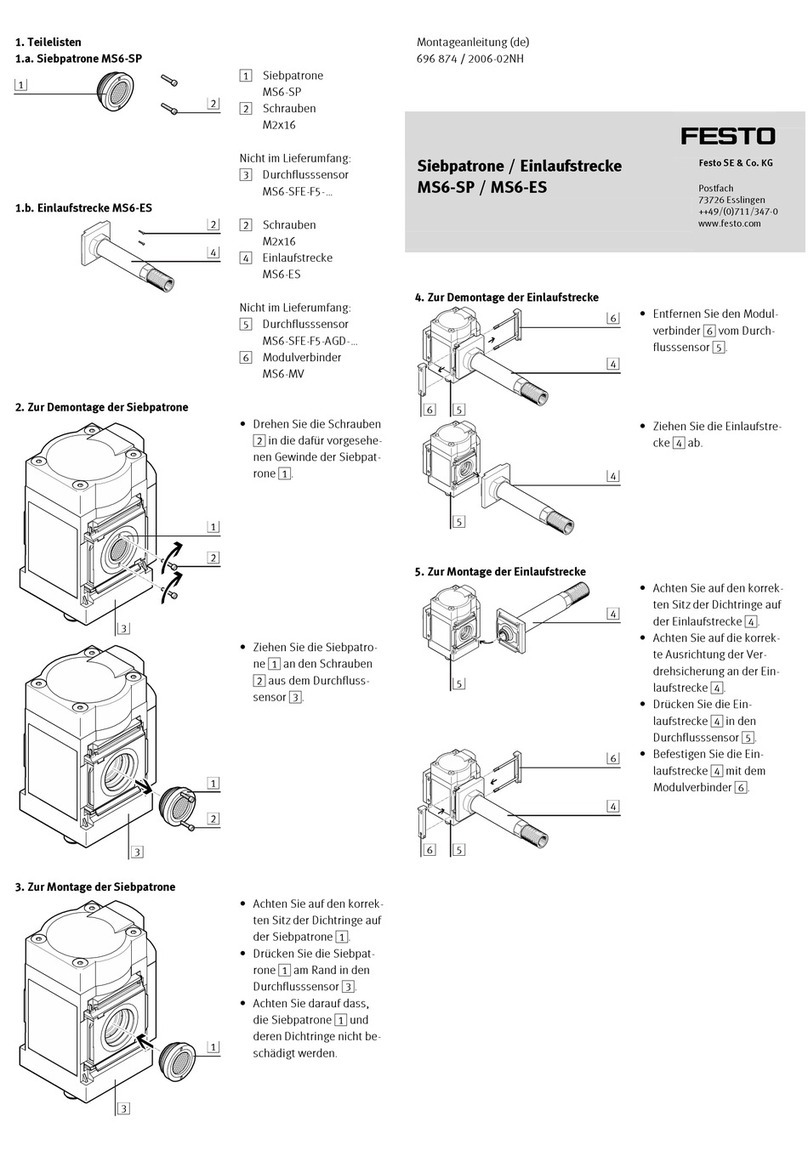

6 Assembly

Limited rotation angle of the robot joint.

The rotation angle of the front robot joint is restricted due to the size and position

of the vacuum generator, as well as the cable installation.

• To prevent damage, restrict the rotation angle in the software.

1. Position adapter plate on the robot flange 1 and secure with socket head

screws 4. Tightening torque: 8Nm

2. Plug in distance piece 7 to the vacuum generator 8. (Only robots

UR10/UR10e/UR16e)

3. Position vacuum generator 8 on robot with adapter plate and secure it with

socket head screws aB. Tightening torque: 3Nm.

4. Screw the suction cup with connection 6 into the vacuum port. Tightening

torque: 11Nm

When using other suction cups with connection

è 9 Conversion of suction cup with connector

8123238

OVEL-...-A-RA1

Suction gripper kit for robots

8123238

202004

[8123240]

Operating instructions

Festo SE & Co. KG

Ruiter Straße 82

73734 Esslingen

Germany

+49 711 3470

www.festo.com