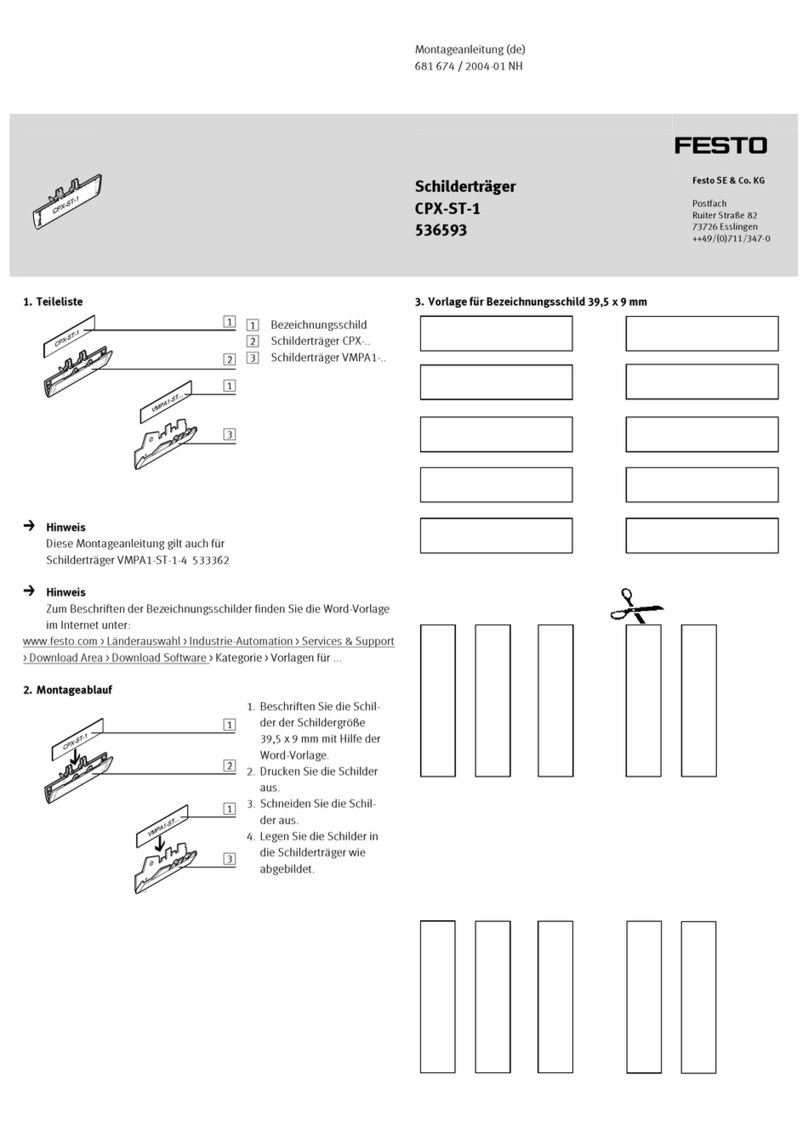

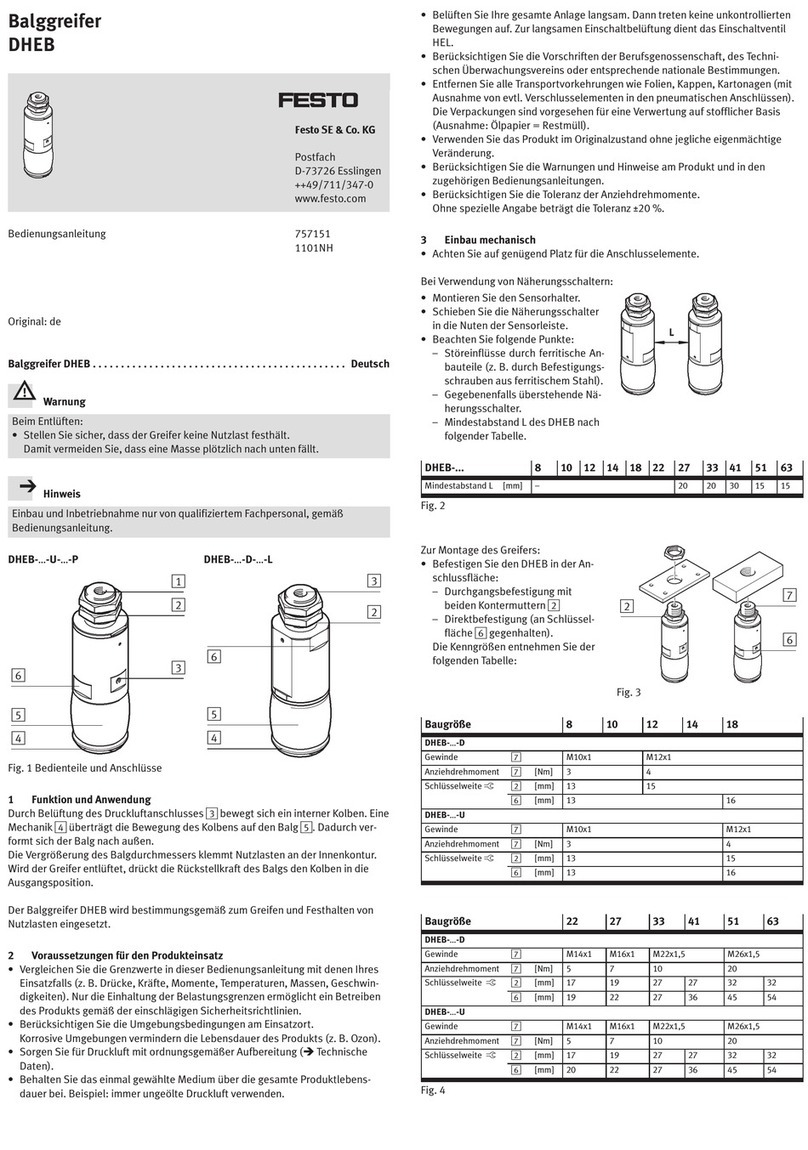

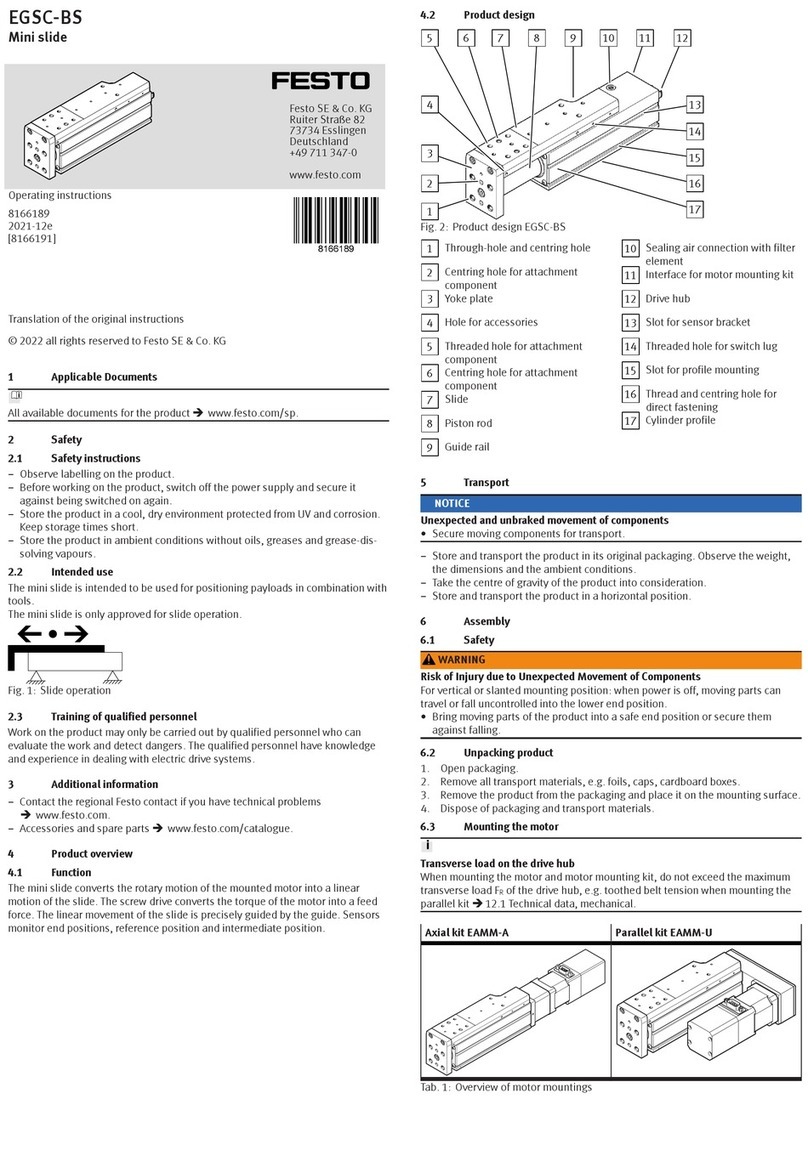

Adjusting product

Fig. 3: Loosen lock nut

1. Position the mass to be cushioned at the intended end position.

2. Loosen the lock nut on the side of the cross-hole nut.

3. Adjust the position of the stop element in accordance with the mounting.

When mounting in drilled hole When mounting in thread

Turn the loaded lock nut in the desired direc-

tion. If necessary, hold the stop element

against the cross-hole nut.

Turn the cross-hole nut in the desired direc-

tion.

One revolution corresponds to approx. 1 mm stroke change.

4. Fix the position of the stop element. At the same time, tighten the lock nut on

the side of the cross-hole nut.

5.1 Mounting

5.2 Aligning product

–Observe the axial direction of force of the moving mass to the axis of the shock

absorber.

–The mass must contact the piston rod over a wide area.

Force direction, max. deviation Alignment of the mass

Tab. 5: Permissible axial force direction and alignment of the moving mass

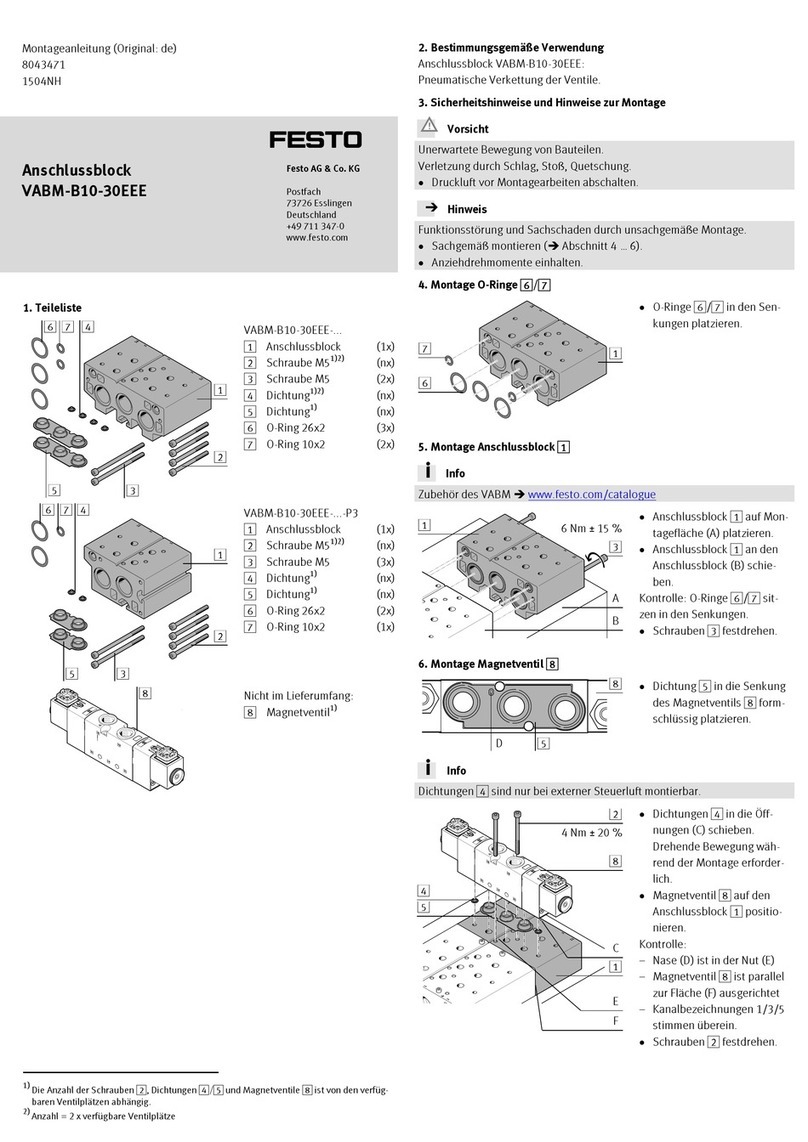

5.3 Mounting accessories

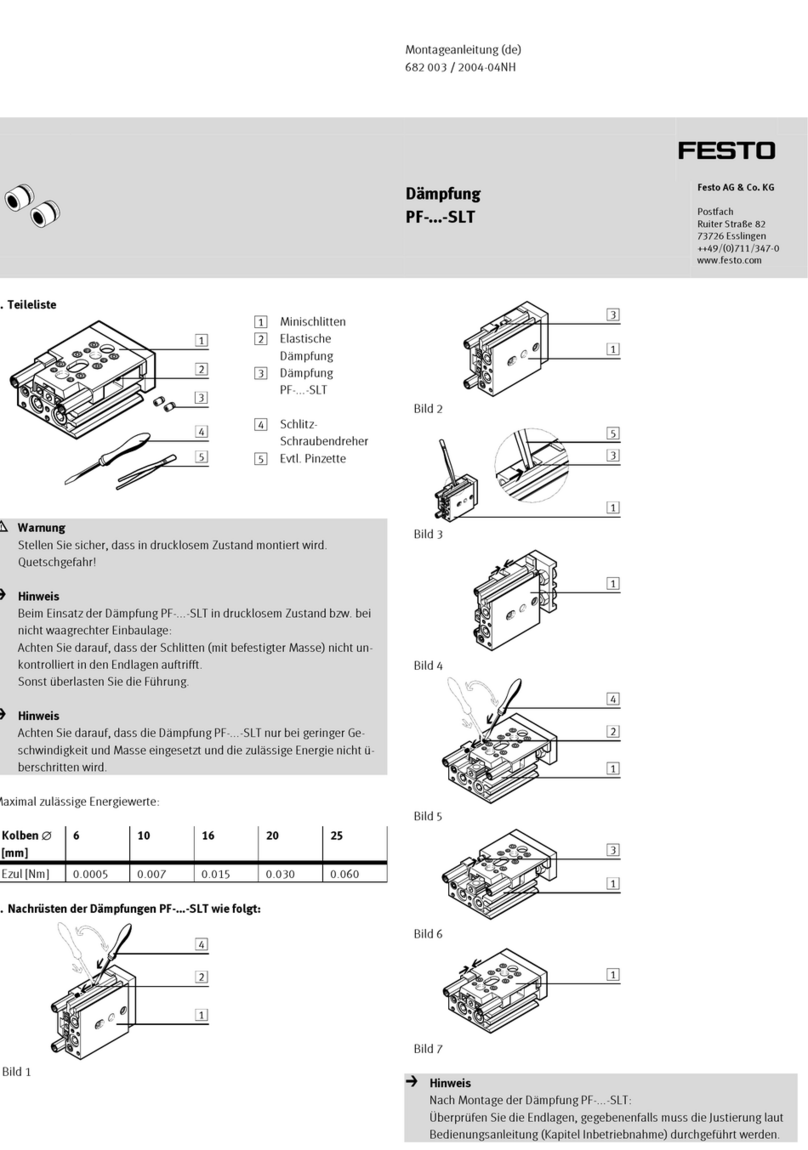

Mounting optional proximity switch

Fig. 4: Mounting proximity switches

Slot for proximity switch

Proximity switch (optional)

•Place the proximity switch in the slot and fasten it in accordance with the end

position of the shock absorber.

6 Commissioning

6.1 Executing test run

1. Start the test run at the drive at reduced velocity.

2. If necessary, readjust the position of the stop element.

3. Gradually increase the velocity of the drive to the operating value in steps.

ÄIf set correctly, the end position is reached without a hard stop.

With hard stop:

–Reduce the impact velocity if necessary.

–Check function and design of the stop element.

6.2 Notes on operation

Energy absorption

• Only use the shock absorber within the permissible range of 25% to 100% of

the maximum energy absorption è 10 Technical data.

Recommendation: use the shock absorber within the optimum range from

50% to 80% of the maximum energy absorption.

Energy absorption Note

0 … 25% Unfavourable; fluid leakage at the shock absorber may be

increased

25 … 50% Permitted

50 … 80% Optimal

80 … 100% Permitted

> 100% Impermissible

Tab. 6: Energy absorption of the shock absorber

Cushioning effect

The viscosity of the hydraulic fluid declines over its operating life due to the

generated friction heat. This can reduce the cushioning effect.

7 Maintenance

Maintenance interval Maintenance work

Every 2 million load changes Check shock absorber:

–sealing, no fluid leakage

–Cushioning distance s è 10 Technical data

In case of leakage, hard stop or cushioning distance too short:

replace shock absorber.

Every 5 million load changes Replace rubber buffer.

Every 10 million load changes Replace shock absorber.

Tab. 7: Maintenance schedule

The hydraulic fluid in the shock absorber cannot be topped up or changed.

The shock absorber cannot be repaired.

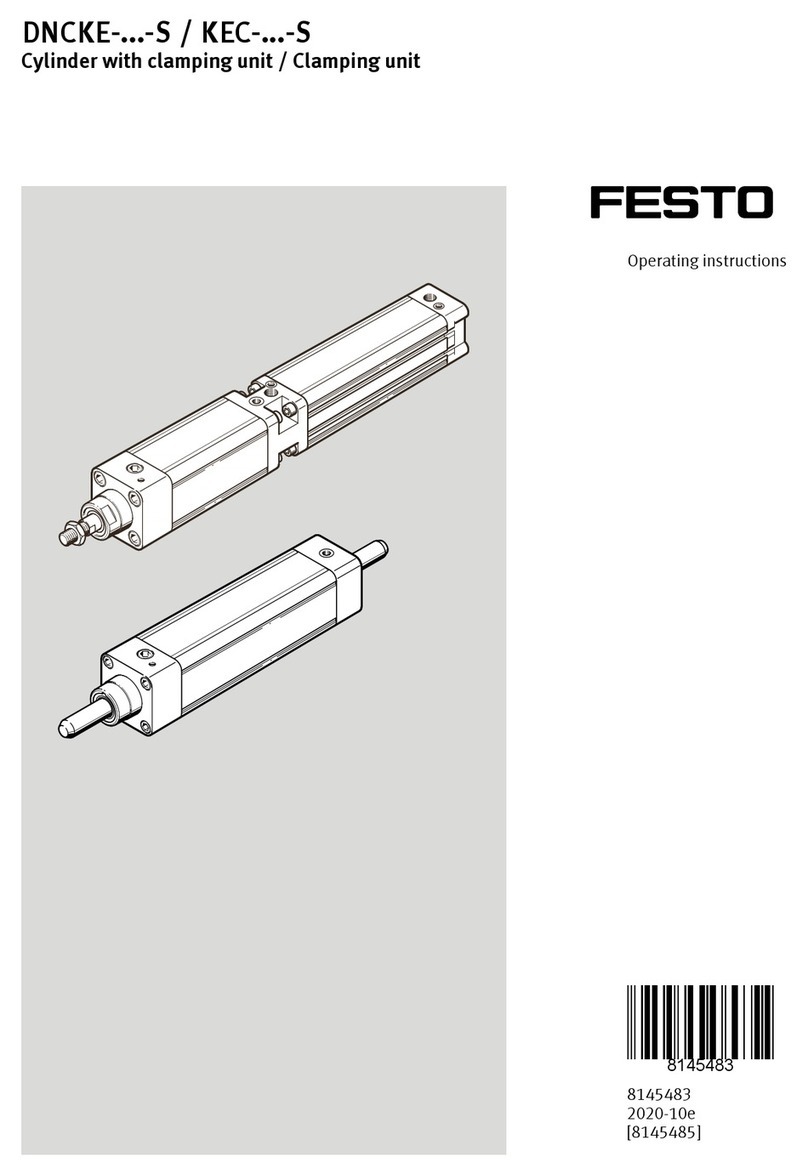

7.1 Replacing shock absorber

Fig. 5: Replacing shock absorber

Shock absorber

Spanner flat

Nut for securing the shock absorber

Stop plunger

Connecting clip

1. Release the load on the stop plunger 6.

2. Loosen the nut 3 on the shock absorber.

3. Unscrew the shock absorber, if necessary with a tool on the spanner flat.

4. If the connecting clip aA was removed with the shock absorber, press the

connecting clip on the new shock absorber.

5. Screw in the new shock absorber to the stop.

6. Tighten the nut 3 to the tightening torque.

Size 5 7 8

Nut 3

Tightening torque

[Nm] 2 3 5

Tolerance ± 20%

7. Actuate the stop plunger slowly until it reaches the end position and then

release the load.

ÄThe connecting clip clicks into place.

8Fault clearance

Malfunction Possible cause Remedy

Leakage/fluid leakage Shock absorber faulty Replace shock absorber.

Noisy impact at the start of the

stroke

Rubber buffer worn Replace rubber buffer

(YSRWJ-7/8 only).

Hard stop in the end position Stop element overloaded Reduce impact velocity or

check the layout of the stop

element.

Shock absorber faulty Replace shock absorber.

Malfunction during position

sensing

Incorrect position of proximity

switches

Correct position of proximity

switches.

Incorrect proximity switch type

used

Only use proximity switches

type SME/SMT-8-...-B.

Proximity switch defective Replace proximity switch.

Ferritic parts in the vicinity of

the proximity switch

Use parts made from non-mag-

netic materials.

Tab. 8: Fault clearance

9Dismantling and disposal

CAUTION

The product contains pressurised hydraulic fluid that can escape in an uncon-

trolled manner if the housing is damaged.

The hydraulic fluid can injure people's eyes and skin and damage the environ-

ment.

• Have the product disposed of by a qualified waste disposal company.

• Do not destroy the product in order to drain the hydraulic fluid.