Translation of the original instructions

© 2019 all rights reserved to Festo SE & Co. KG

1 Applicable Documents

All available documents for the product èwww.festo.com/sp.

Observe further applicable documents:

– Motor instruction manual

– Axis instruction manual

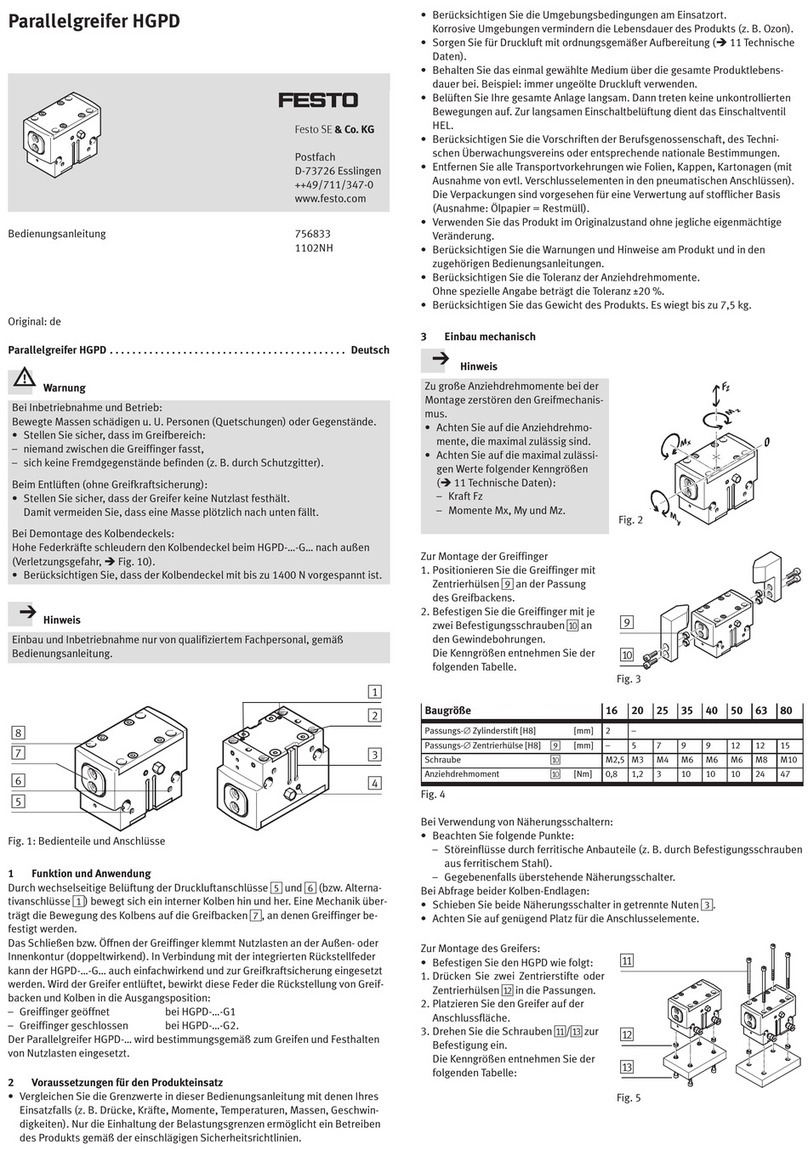

2 Safety

2.1 Safety Instructions

– Only assemble the product on components that are in a condition to be safely

operated.

– Clean shafts. The coupling hubs[1] grip without slipping only on dry and

grease-free drive shafts.

– Maintain proper alignment of the coupling hubs[1].

– Support the combination:

– if there are protruding or heavy motor attachments

– if there are severe vibrations or oscillation/shock loads

– Perform a homing procedure each time after disconnecting or turning the

motor.

– Select required mounting components. The kit contains all the mounting com-

ponents that may be required.

– Select the correct screw length for the screws[7] depending on the axis. The

screws[7] are labelled correspondingly.

– Observe tightening torques. Unless otherwise specified, the tolerance

is±20%.

If they are exceeded, the cover screws of the axis will loosen during disas-

sembly.

– Select the seal that fits the axis[4].

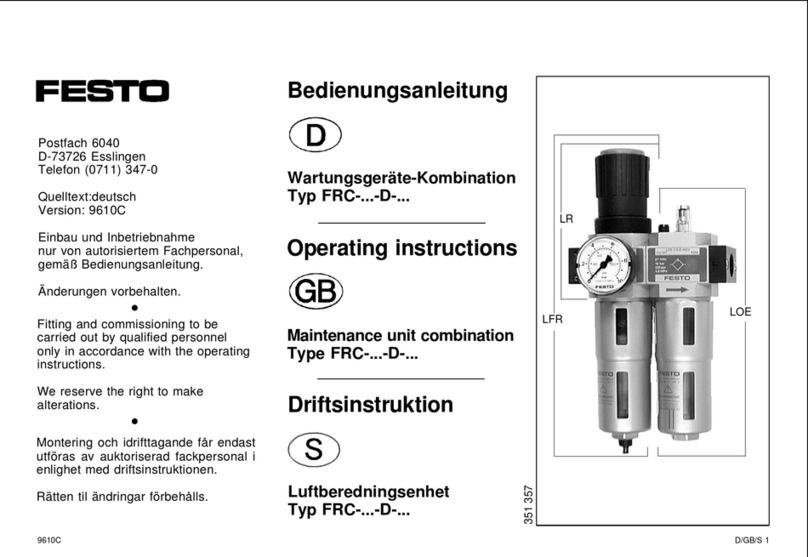

2.2 Intended use

2.2.1 Usage

Connecting an axis to a motor in axial configuration to the driven shaft. Fulfils

degree of protection IP65.

2.2.2 Permissible Axes and Motors

NOTICE!

Overloading can cause malfunction and material damage.

The motor’s output variables must not exceed the permissible values of the com-

ponents used.

Permissible values èwww.festo.com/catalogue.

• Limit the motor’s output variables accordingly.

• Derive the axis and motor from the interface codes.

Example: EAMM-A-D32-42A

D32: Axis interface

42A: Motor interface

Example: EAMM-A-D32-42A-S1

D32: Axis interface

42A: Motor interface

Axis interface Axis1)

D32 ESBF-32

1) electric cylinderESBF

Tab. 1

Motor interface Motor1)

42A EMMS-ST-42, third-party motor

1) stepper motor EMM...-ST

Tab. 2

2.3 Training of Qualified Personnel

Mounting only by qualified personnel.The qualified personnel must be familiar

with the assembly of mechanical drive components.

3 Additional information

– Accessories èwww.festo.com/catalogue.

4 Scope of Delivery

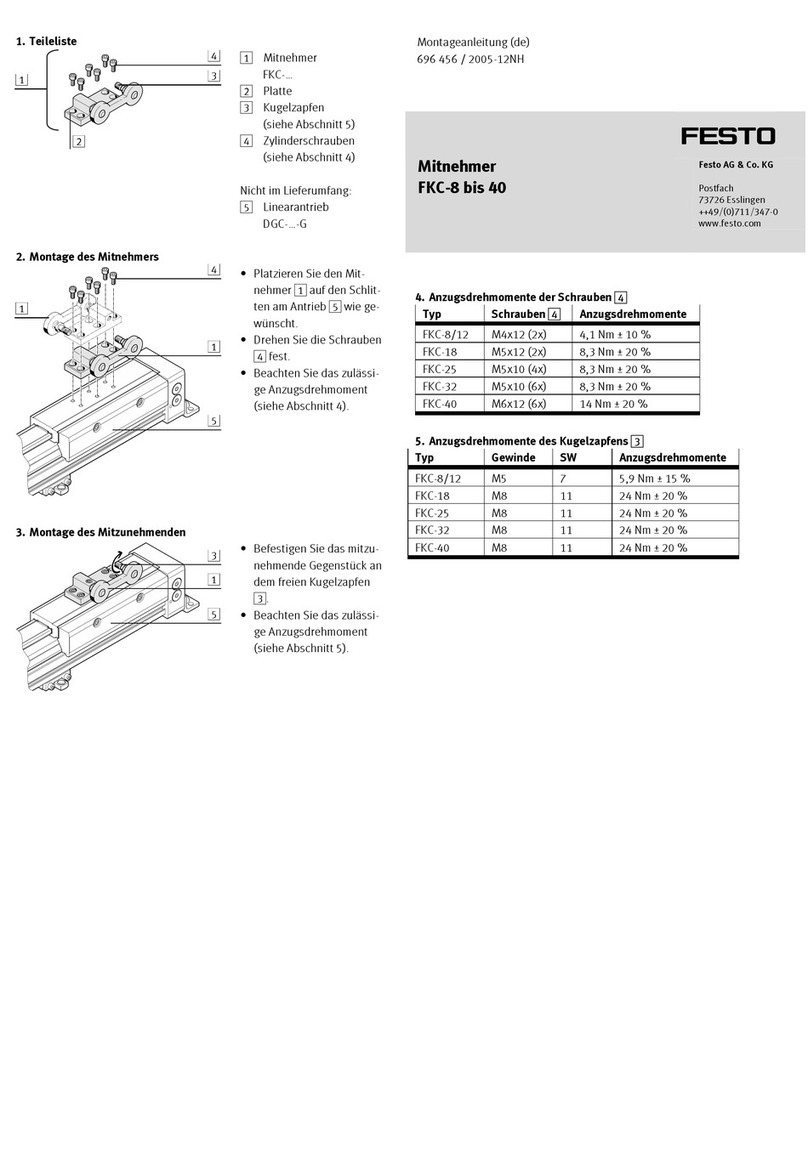

1Coupling hub (2x)

2Locking screw (2x)

4Seal (1x)

5Coupling housing (1x)

7Screw (4x)

8Seal (1x)

9Motor flange (1x)

10 Screw (4x)

11 Seal (1x)

12 Screw (4x)

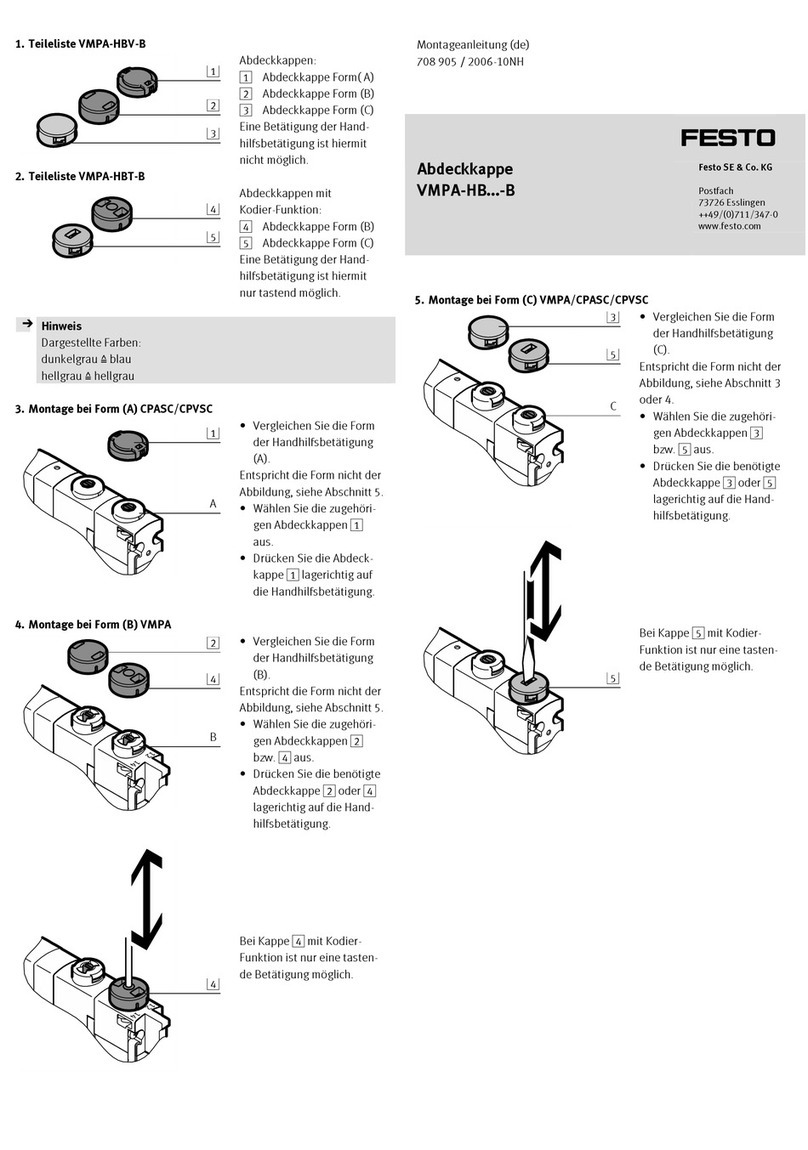

Fig. 1 Scope of Delivery

5 Mounting

5.1 Assembly

5.1.1 Coupling Preassembly

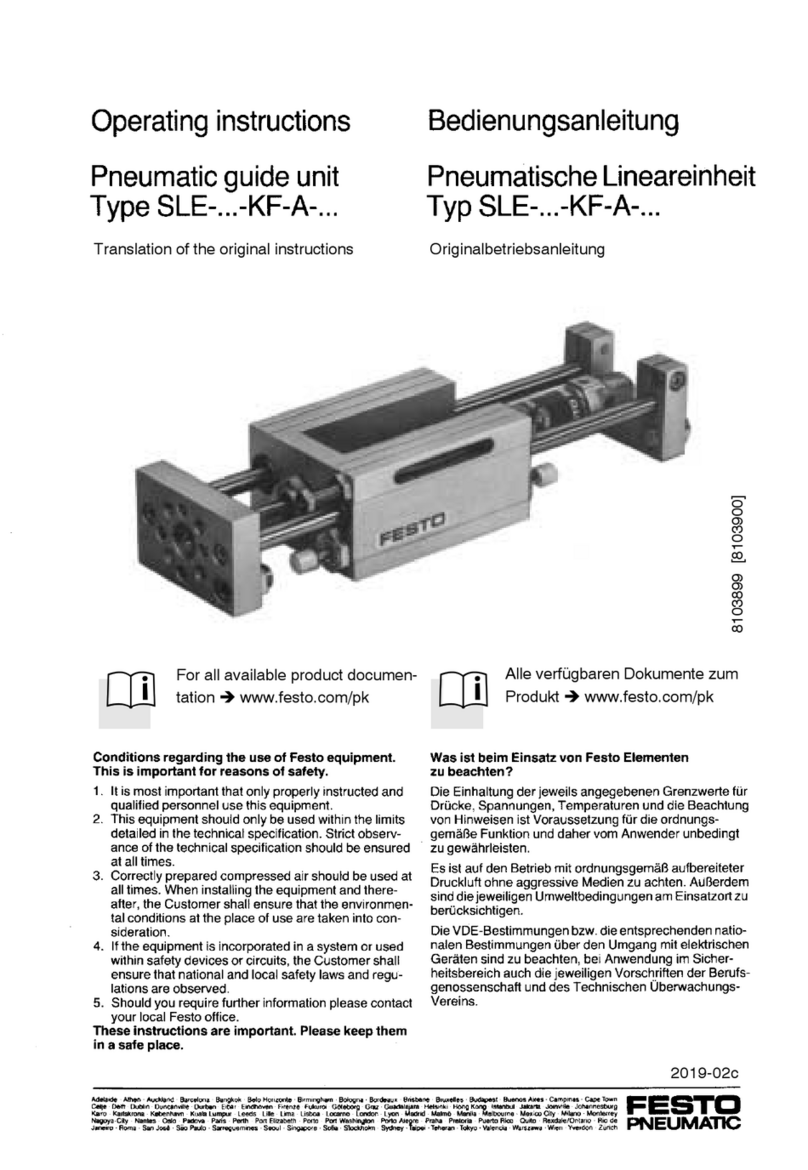

Fig. 2 Disconnect the coupling

1. Pull apart coupling.

2. Place the elastomer spider[A] on one of the two coupling hubs[1].

3. Loosen locking screws[2].

Fig. 3 Push on coupling hub, axis-side

• Push coupling hub[1] with the matching drilled hole onto the drive shaft[B].

Fig. 4 Align coupling hub, axis-side

8113594

EAMM-A-D...-...A/P/R-S1-7

Axial kit

8113594

2019-11d

[8113596]

Instructions| Assembly

Festo SE & Co. KG

Ruiter Straße 82

73734 Esslingen

Germany

+49 711 347-0

www.festo.com