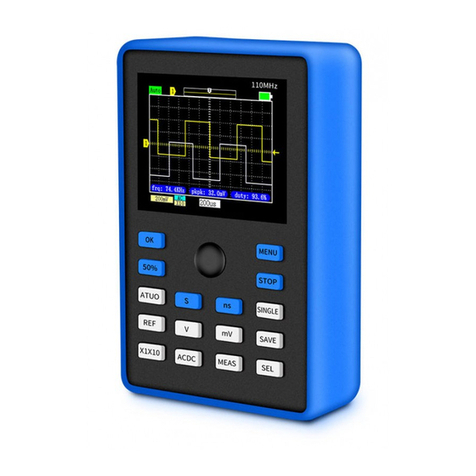

Fnirsi 1013D Instruction sheet

Product

instructions

FNIRSI-1013D

Two

channel

plate

oscilloscope

YOUR

GOOD

TEST

TOOL

Product

introduction

FNIRSI-1013D

is

a

full-featured,

highly

practical,

cost-effective

dual-channel

flat-panel

oscilloscope

launched

by

FNIRSI

for

the

maintenance

and

R

&

D

industry;

this

oscillo-

scope

has

a

real-time

sampling

rate

of

1GSa

/

s

and

an

analog

bandwidth

of

100MHz

*

2.

With

complete

trigger

function

(single

/

normal

/

automatic),

it

can

be

used

freely

for

periodic

analog

signals

or

non-periodic

digital

signals;

the

built-in

high-voltage

protection

module

can

tolerate

a

continuous

voltage

of

up

to

400V.

Oscilloscope

burnout

accident

caused

by

the

probe

being

turned

to

the

10X

position.

Large

time

base

scroll

mode

can

monitor

slow

level

changes;

Equipped

with

highly

efficient

one-key

AUTO,

which

can

display

the

measured

waveform

without

tedious

adjust-

ments;

the

display

is

equipped

with

a

7-inch

800

*

480

resolution

high-definition

LCD

LCD

screen,

and

the

operation

method

is

capacitor

Screen

touch

+

gesture

operation,

extremely

convenient;

cursor

measurement

function,

you

do

not

need

to

read

the

background

scale

unit

and

quantity

when

manually

reading

the

amplitude

and

frequency

parameters,

and

you

can

directly

get

the

peak,

peak

and

frequency

without

conversion;

extremely

convenient

screenshot

And

waveform

storage

function,

built-in

1GB

storage

space,

can

store

up

to

1000

screenshots

+

1000

sets

of

waveform

data,

the

storage

process

is

simple

and

fast,

save

the

current

waveform

anytime,

anywhere

with

a

single

touch,

no

cumbersome

prompts

and

choices,

keep

calm

The

current

data

is

saved

in

the

place,

which

is

very

convenient;

the

powerful

waveform

picture

manag-

er

supports

thumbnail

browsing,

viewing,

detailed

viewing,

page

turning,

deletion

and

waveform

zooming

in,

zooming

out,

moving,

etc.

to

facilitate

secondary

analysis.

The

fuselage

is

equipped

with

a

USB

interface,

which

can

be

connected

to

a

computer

to

share

its

screenshots

with

the

computer,

which

is

convenient

for

secondary

analysis;

Li

Shayu's

graphic

display

function

can

be

used

to

determine

the

amplitude,

frequency,

and

phase

contrast

of

two

groups

of

signals;

Analysis

of

the

harmonic

components

of

the

signal;

built-in

6000mah

high-quality

lithium

battery,

which

can

last

for

4

hours

on

a

full

charge,

and

can

be

used

while

charging

like

a

notebook

The

bandwidth

of

the

1X

probe

file

is

5MHz,

and

the

bandwidth

of

the

10X

probe

file

is

100MHz.

When

measuring

higher

than

5MHZz,

you

need

to

turn

the

switch

on

the

probe

handle

to

the

10X

position,

and

the

oscilloscope

must

be

set

to

the

10X

position

.

Otherwise

the

signal

will

be

greatly

attenuated,

as

is

the

case

with

all

oscillo-

scopes.

Because

the

probe

line

of

the

oscilloscope

itself

has

a

capacitance

of

up

to

100

—

300pF,

it

is

a

very

large

capacitance

for

high-frequency

signals!

The

signal

has

been

greatly

attenuated

through

the

probe

to

the

input

of

the

oscilloscope,

and

the

equiva-

lent

bandwidth

is

5MHz.

Therefore,

in

order

to

match

the

hundreds

of

pF

of

the

probe

line,

the

input

of

the

probe

line

is

attenuated

by

10

times

(the

switch

is

in

the

10X

range).

A

few

hundred

pF

capacitors

are

just

used

for

impedance

matching.

At

this

time,

the

bandwidth

is

100MHz.

Note

that

only

probes

with

a

bandwidth

of

100MHz

or

higher

can

be

used.

ZOuS/div

vPp

:1.960

EU

vP

:1.0zv

Freq

:

20.Oktiz

VPP

:1.940

Frea

:

5.00KHz

RUN

VPP

:1.96U

VP

:1.020

Freq

:

20.0RHz

VPP

:1.94U

Freq

:5.00RHz

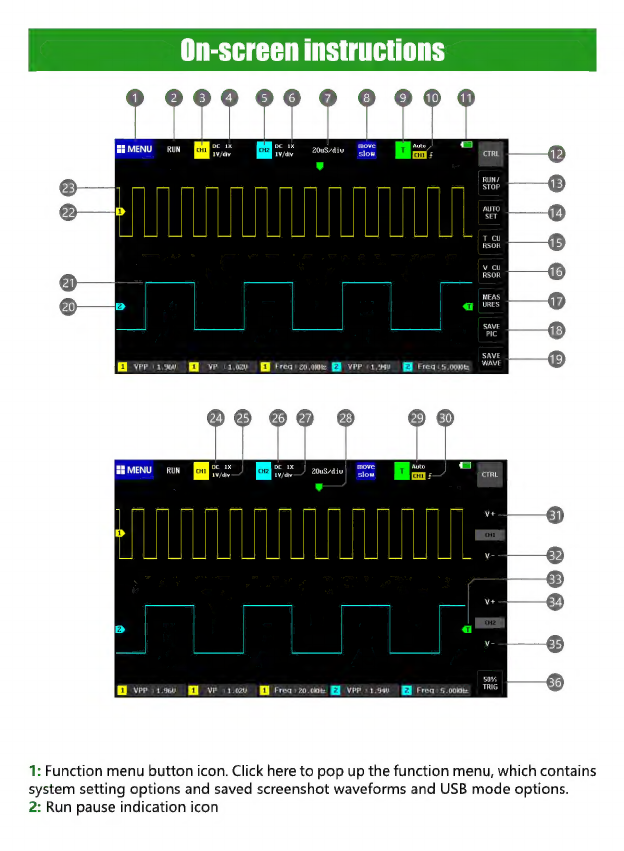

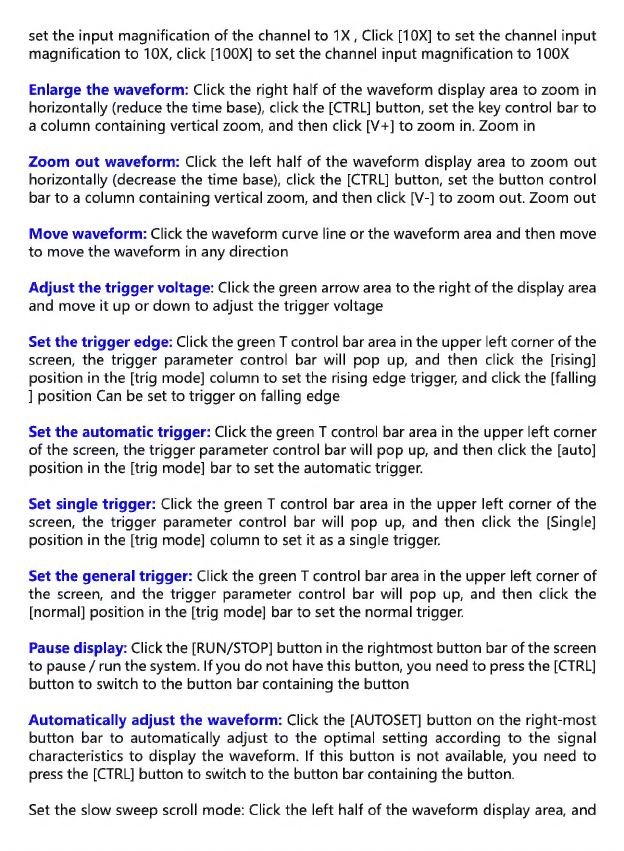

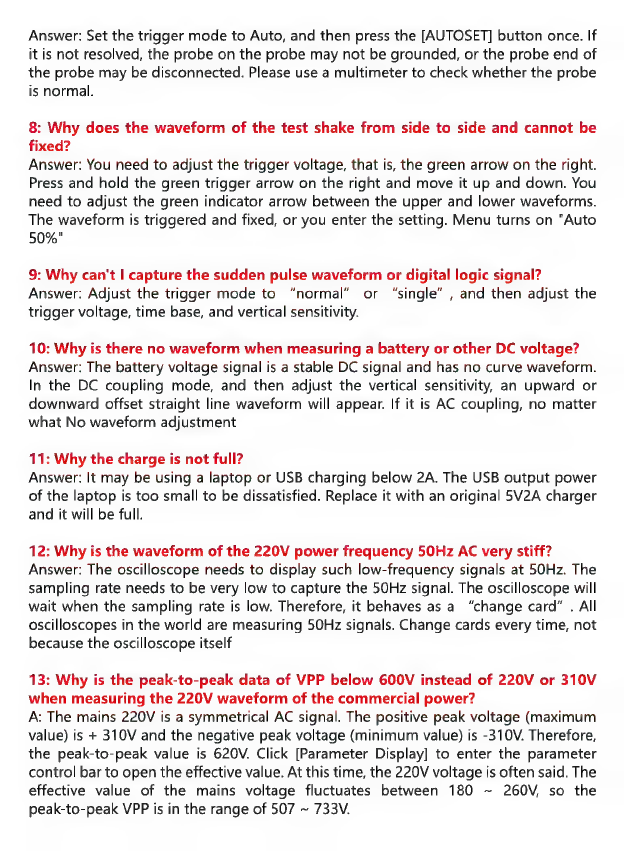

1:

Function

menu

button

icon.

Click

here

to

pop

up

the

function

menu,

which

contains

system

setting

options

and

saved

screenshot

waveforms

and

USB

mode

options.

2:

Run

pause

indication

icon

3:

Channel

1

position

indication

means

that

the

parameters

near

this

block

area

are

all

parameters

of

Channel

1.

Clicking

this

area

will

pop

up

the

Channel

1

control

bar

4:

Probe

magnification

of

channel

1,

divided

into

1X,

10X,

100X

three

options

5:

Channel

2

position

indication

means

that

the

parameters

near

this

block

area

are

the

parameters

of

Channel

2.

Clicking

this

area

will

pop

up

the

Channel

2

control

bar

6:

Probe

magnification

of

channel

2,

divided

into

1X,

10X,

100X

three

options

7:

System

time

base

refers

to

the

length

of

time

represented

by

a

large

grid

in

the

horizontal

direction,

which

is

determined

by

the

sampling

rate.

The

larger

the

time

base,

the

slower

the

sampling

rate,

and

vice

versa.

8:

The

movement

speed

under

the

gesture

movement

operation.

[Move

coarse

adjustment]

means

fast

movement,

[Move

fine

adjustment]

means

slow

movement.

9:

Trigger

indication

icon,

which

means

that

the

parameters

near

this

block

area

are

all

trigger

related

parameters.

Clicking

this

area

will

pop

up

the

trigger

control

bar

10:

trigger

channel,

divided

into

CH1,

CH2

options

11:

Battery

remaining

power

indicator

icon,

green

block

indicates

remaining

power

12:

Main

interface

control

bar

function

switch

button,

click

this

button

to

switch

between

2

types

of

button

bar

13:

Run

pause

button,

click

this

button

to

switch

between

running

and

pause

14:

One-button

automatic

adjustment

button.

Clicking

this

button

will

automatically

identify

the

signal

and

set

the

system

to

the

best

parameters

to

display

the

waveform.

15:

Time

cursor

switch

button,

click

this

button

to

turn

the

cursor

measurement

function

on

and

off

16:

Voltage

cursor

switch

button,

click

this

button

to

turn

cursor

measurement

on

and

off

17:

Measurement

parameter

selection

function.

Click

this

button

to

pop

up

the

parameter

selection

bar.

Click

the

parameter

in

the

selection

bar

to

open

the

parame-

ter

display.

18:

One-click

screenshot

button,

click

this

button

to

take

a

screenshot

of

the

entire

screen

and

automatically

save

it

to

the

internal

storage

space

19:

One-click

waveform

save

button.

Clicking

this

button

will

save

all

waveform

data

of

2

channels

to

the

internal

storage

space.

20:

The

arrow

indicating

the

baseline

position

of

channel

2

is

the

position

of

OV

potential

21:

Waveform

data

of

channel

2

22:

Channel

1

baseline

position

indicating

arrow,

which

is

the

position

of

OV

potential

23:

Waveform

data

of

channel

1

24:

Input

coupling

indicator

icon

of

channel

1,

there

are

two

options

of

DC

and

AC,

DC

means

DC

coupling,

AC

means

AC

coupling

25:

The

vertical

sensitivity

indicator

of

channel

1

refers

to

the

voltage

represented

by

a

large

division

in

the

vertical

direction.

26:

Input

coupling

indicator

of

channel

2.

There

are

two

options:

DC

and

AC.

DC

means

DC

coupling

and

AC

means

AC

coupling.

27:

The

vertical

sensitivity

indicator

of

channel

2

refers

to

the

voltage

represented

by

a

large

grid

in

the

vertical

direction.

28:

Trigger

X

position

indicating

arrow,

which

refers

to

the

trigger

point

here

29:

Trigger

mode

indication

icon,

divided

into

Auto,

Single,

Normal;

Auto

is

automatic

trigger,

Sinle

is

single

trigger,

Normal

is

normal

trigger

30:

trigger

edge

indication

icon,

the

arrow

points

up

to

the

rising

edge

to

trigger,

the

arrow

points

down

to

the

falling

edge

to

trigger

31:

Channel

1

vertical

sensitivity

increase

button,

that

is,

zoom

in

vertically.

Clicking

this

button

will

zoom

in

the

vertical

direction,

that

is,

stretch

vertically.

32:

Channel

1

vertical

sensitivity

reduction

button,

that

is,

the

vertical

direction

is

reduced.

Click

this

button

to

reduce

the

waveform

in

the

vertical

direction,

that

is,

vertically.

33:

trigger

voltage

indication

icon,

that

is,

the

trigger

threshold

34:

Channel

2

vertical

sensitivity

increase

button,

that

is,

zoom

in

vertically.

Click

this

button

to

zoom

in

the

vertical

direction,

that

is,

stretch

vertically.

35:

Channel

2

vertical

sensitivity

reduction

button,

that

is,

the

vertical

direction

is

reduced.

Clicking

this

button

waveform

will

be

reduced

in

the

vertical

direction,

that

is,

vertically

reduced.

36:

50%

trigger

button

refers

to

setting

the

trigger

voltage

to

the

middle

position

of

the

waveform

amplitude.

Note

that

it

cannot

be

used

for

PWM

waveforms

with

dead

time.

This

type

of

waveform

requires

the

trigger

arrows

to

be

set

to

both

sides

of

the

waveform.

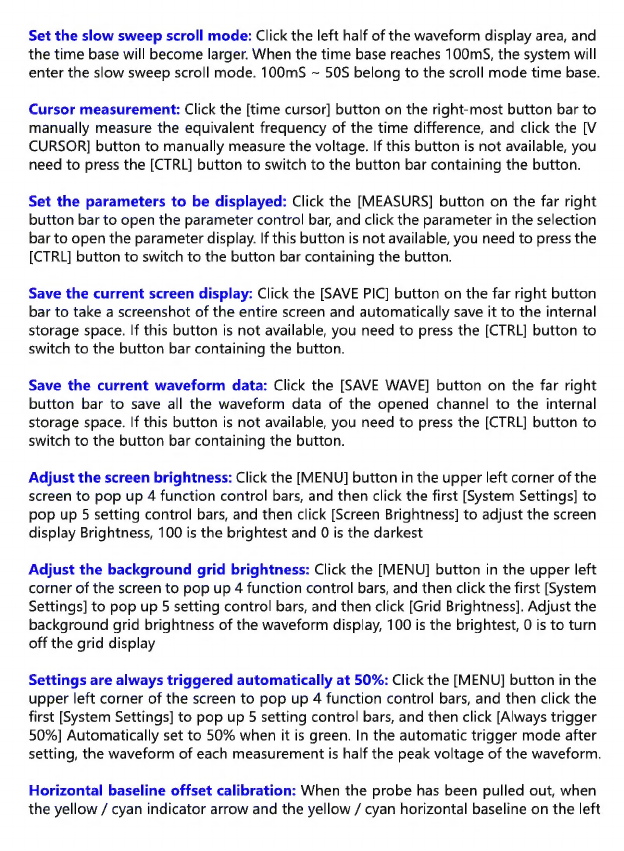

1:

System

function

menu

key

area,

click

this

area

to

pop

up

system

function

and

setting

menu

2:

Channel

1

control

bar

key

area,

click

this

area

to

pop

up

the

parameter

control

bar

of

channel

1

3:

Channel

2

control

bar

key

area,

click

this

area

to

pop

up

the

parameter

control

bar

of

channel

2

4:

Movement

speed

button

area,

click

here

to

switch

between

fast

movement

and

slow

movement

5:

trigger

control

bar

key

area,

click

here

will

pop

up

trigger

parameter

control

bar

6:

trigger

voltage

button

area,

press

here

and

slide

up

and

down

to

adjust

the

trigger

voltage

(trigger

threshold)

7:

The

time

base

shrinks

the

key

area,

that

is,

the

waveform

is

stretched

and

enlarged

in

the

horizontal

direction.

The

display

area

to

the

right

of

the

centerline

of

the

background

grid

is

the

key

area.

8:

The

time base

increases

the

key

area,

that

is,

the

waveform

is

pushed

horizontally

to

shrink.

The

area

to

the

left

of

the

centerline

of

the

background

grid

is

the

key

area.

9:

Channel

2

horizontal

baseline

button

area.

Press

here

and

slide

up

and

down

to

adjust

the

baseline

position

of

Channel

2.

You

can

also

directly

click

the

waveform

to

move

the

horizontal

baseline

(waveform

moves

up

and

down).

The

left

and

right

movement

buttons

of

the

waveform

are

the

entire

display.

Area

10:

Channel

1

horizontal

baseline

button

area.

Press

here

and

slide

up

and

down

to

adjust

the

baseline

position

of

channel

1.

You

can

also

directly

click

the

waveform

to

move

the

horizontal

baseline

(waveform

moves

up

and

down).

The

left

and

right

movement

buttons

of

the

waveform

are

the

entire

display.

Area

Operation

instructions

Turn

channel

1

/

channel

2

on

or

off:

Click

the

yellow

CH1

/

CH2

control

bar

area

in

the

upper

left

corner

of

the

screen,

the

parameter

control

bar

for

channel

1

/

channel

2

will

pop

up,

and

then

click

the

[ON]

position

in

the

[open

CH1]]

column

to

enable

the

channel,

and

click

the

[OFF]

position

to

close

it.

The

channel

Turn

FFT

on

or

off:

Click

the

yellow

CH1

/

CH2

control

bar

area

in

the

upper

left

corner

of

the

screen,

the

parameter

control

bar

for

channel

1

/

channel

2

will

pop

up,

and

then

click

the

[ON]

position

in

the

[open

FFT]

column

to

enable

the

FFT

of

the

channel.

Click

the

[Close]

position

to

Can

turn

off

the

FFT

of

this

channel

Set

the

input

coupling

mode:

Click

the

yellow

CH1

/

CH2

control

bar

area

in

the

upper

left

corner

of

the

screen,

the

parameter

control

bar

for

channel

1

/

channel

2

will

pop

up,

and

then

click

the

[DC]

position

in

the

[Coupling]

column

to

set

the

channel

input

coupling

to

DC

coupling,

and

click

[AC

]

Position

to

set

the

channel

input

coupling

to

AC

coupling

Set

the

probe

input

magnification:

Click

the

yellow

CH1

/

CH2

control

bar

area

in

the

upper

left

corner

of

the

screen,

the

parameter

control

bar

for

channel

1

/

channel

2

will

pop

up,

and

then

click

the

[1X]

position

in

the

[probe

mode]

column

to

set

the

input

magnification

of

the

channel

to

1X,

Click

[10X]

to

set

the

channel

input

magnification

to

10X,

click

[100X]

to

set

the

channel

input

magnification

to

100X

Enlarge

the

waveform:

Click

the

right

half

of

the

waveform

display

area

to

zoom

in

horizontally

(reduce

the

time

base),

click

the

[CTRL]

button,

set

the

key

control

bar

to

a

column

containing

vertical

zoom,

and

then

click

[V+]

to

zoom

in.

Zoom

in

Zoom

out

waveform:

Click

the

left

half

of

the

waveform

display

area

to

zoom

out

horizontally

(decrease

the

time

base),

click

the

[CTRL]

button,

set

the

button

control

bar

to

a

column

containing

vertical

zoom,

and

then

click

[V-]

to

zoom

out.

Zoom

out

Move

waveform:

Click

the

waveform

curve

line

or

the

waveform

area

and

then

move

to

move

the

waveform

in

any

direction

Adjust

the

trigger

voltage:

Click

the

green

arrow

area

to

the

right

of

the

display

area

and

move

it

up

or

down

to

adjust

the

trigger

voltage

Set

the

trigger

edge:

Click

the

green

T

control

bar

area

in

the

upper

left

corner

of

the

screen,

the

trigger

parameter

control

bar

will

pop

up,

and

then

click

the

[rising]

position

in

the

[trig

mode]

column

to

set

the

rising

edge

trigger,

and

click

the

[falling

]

position

Can

be

set

to

trigger

on

falling

edge

Set

the

automatic

trigger:

Click

the

green

T

control

bar

area

in

the

upper

left

corner

of

the

screen,

the

trigger

parameter

control

bar

will

pop

up,

and

then

click

the

[auto]

position

in

the

[trig

mode]

bar

to

set

the

automatic

trigger.

Set

single

trigger:

Click

the

green

T

control

bar

area

in

the

upper

left

corner

of

the

screen,

the

trigger

parameter

control

bar

will

pop

up,

and

then

click

the

[Single]

position

in

the

[trig

mode]

column

to

set

it

as

a

single

trigger.

Set

the

general

trigger:

Click

the

green

T

control

bar

area

in

the

upper

left

corner

of

the

screen,

and

the

trigger

parameter

control

bar

will

pop

up,

and

then

click

the

[normal]

position

in

the

[trig

mode]

bar

to

set

the

normal

trigger.

Pause

display:

Click

the

[RUN/STOP]

button

in

the

rightmost

button

bar

of

the

screen

to

pause

/

run

the

system.

If

you

do

not

have

this

button,

you

need

to

press

the

[CTRL]

button

to

switch

to

the

button

bar

containing

the

button

Automatically

adjust

the

waveform:

Click

the

[AUTOSET]

button

on

the

right-most

button

bar

to

automatically

adjust

to

the

optimal

setting

according

to

the

signal

characteristics

to

display

the

waveform.

If

this

button

is

not

available,

you

need

to

press

the

[CTRL]

button

to

switch

to

the

button

bar

containing

the

button.

Set

the

slow

sweep

scroll

mode:

Click

the

left

half

of

the

waveform

display

area,

and

Set

the

slow

sweep

scroll

mode:

Click

the

left

half

of

the

waveform

display

area,

and

the

time

base

will

become

larger.

When

the

time

base

reaches

100mS,

the

system

will

enter

the

slow

sweep

scroll

mode.

100mS

>

50S

belong

to

the

scroll

mode

time

base.

Cursor

measurement:

Click

the

[time

cursor]

button

on

the

right-most

button

bar

to

manually

measure

the

equivalent

frequency

of

the

time

difference,

and

click

the

[V

CURSOR]

button

to

manually

measure

the

voltage.

If

this

button

is

not

available,

you

need

to

press

the

[CTRL]

button

to

switch

to

the

button

bar

containing

the

button.

Set

the

parameters

to

be

displayed:

Click

the

[MEASURS]

button

on

the

far

right

button

bar

to

open

the

parameter

control

bar,

and

click

the

parameter

in

the

selection

bar

to

open

the

parameter

display.

If

this

button

is

not

available,

you

need

to

press

the

[CTRL]

button

to

switch

to

the

button

bar

containing

the

button.

Save

the

current

screen

display:

Click

the

[SAVE

PIC]

button

on

the

far

right

button

bar

to

take

a

screenshot

of

the

entire

screen

and

automatically

save

it

to

the

internal

storage

space.

If

this

button

is

not

available,

you

need

to

press

the

[CTRL]

button

to

switch

to

the

button

bar

containing

the

button.

Save

the

current

waveform

data:

Click

the

[SAVE

WAVE]

button

on

the

far

right

button

bar

to

save

all

the

waveform

data

of

the

opened

channel

to

the

internal

storage

space.

If

this

button

is

not

available,

you

need

to

press

the

[CTRL]

button

to

switch

to

the

button

bar

containing

the

button.

Adjust

the

screen

brightness:

Click

the

[MENU]

button

in

the

upper

left

corner

of

the

screen

to

pop

up 4

function

control

bars,

and

then

click

the

first

[System

Settings]

to

pop

up

5

setting

control

bars,

and

then

click

[Screen

Brightness]

to

adjust

the

screen

display

Brightness,

100

is

the

brightest

and

0

is

the

darkest

Adjust

the

background

grid

brightness:

Click

the

[MENU]

button

in

the

upper

left

corner

of

the

screen

to

pop

up

4

function

control

bars,

and

then

click

the

first

[System

Settings]

to

pop

up

5

setting

control

bars,

and

then

click

[Grid

Brightness].

Adjust

the

background

grid

brightness

of

the

waveform

display,

100

is

the

brightest,

0

is

to

turn

off

the

grid

display

Settings

are

always

triggered

automatically

at

50%:

Click

the

[MENU]

button

in

the

upper

left

corner

of

the

screen

to

pop

up

4

function

control

bars,

and

then

click

the

first

[System

Settings]

to

pop

up

5

setting

control

bars,

and

then

click

[Always

trigger

50%]

Automatically

set

to

50%

when

it

is

green.

In

the

automatic

trigger

mode

after

setting,

the

waveform

of

each

measurement

is

half

the

peak

voltage

of

the

waveform.

Horizontal

baseline

offset

calibration:

When

the

probe

has

been

pulled

out,

when

the

yellow

/

cyan

indicator

arrow

and

the

yellow

/

cyan

horizontal

baseline

on

the

left

of

any

of

the

two

channels

are

not

in

the

same

position,

calibration

is

required.

Click

the

[MENU]

button

in

the

upper

left

corner

of

the

screen

to

pop

up 4

function

control

bars,

and

then

click

the

first

[System

Settings]

to

pop

up

5

setting

control

bars,

and

then

click

[Baseline

Calibration].

You

need

to

unplug

all

the

probes

and

USB

Charge

the

power,

make

sure

it

is

unplugged,

and

then

click

[OK]

to

perform

the

calibration.

View

the

screenshot

after

saving:

Click

the

[MENU]

button

in

the

upper

left

corner

of

the

screen

to

pop

up

4

function

control

bars,

and

then

click

the

second

[Picture

view]

to

enter

the

picture

thumbnail

preview

interface,

which

contains

the

thumbnail

of

the

waveform

of

the

screenshot.

Click

the

thumbnail

to

view

the

screenshot

of

the

waveform

in

full

screen.

Clicking

the

bottom

of

the

screen

will

pop

up

the

control

bar

with

the

return,

delete,

previous,

and

next

control

buttons.

You

can

also

click

[Select

All]

or

[Select]

in

the

preview

interface.

To

delete

View

saved

waveform

data:

Click

the

[MENU]

button

in

the

upper

left

corner

of

the

screen

to

pop

up 4

function

control

bars,

and

then

click

the

third

[Waveform

View]

to

enter

the

waveform

thumbnail

preview

interface,

which

contains

thumbnails

of

the

saved

waveforms.,

Click

the

thumbnail

to

analyze

the

waveform

in

full

screen,

you

can

move

and

zoom

the

group

of

waveforms

arbitrarily,

you

can

also

click

the

cursor

to

measure

manually,

you

can

also

click

the

parameter

control

panel

to

reselect

the

parameters

to

be

displayed,

etc.

]

Refers

to

the

previous

set

of

waveforms,

[page

down]

refers

to

the

next

set

of

waveforms

Delete

the

saved

waveform:

In

the

full-screen

view

waveform

interface,

click

the

[Delete

Wave]

button

on

the

far

right

button

bar

to

delete

this

group

of

waveforms.

If

this

button

is

not

available,

you

need

to

press

the

[CTRL]

button

to

switch

to

the

button

bar

containing

the

button.

Take

a

screenshot

in

the

waveform

browser:

In

the

full-screen

view

of

the

waveform

interface,

click

the

[SAVE

PIC]

button

on

the

far

right

button

bar

to

take

a

screenshot

of

the

entire

screen

and

automatically

save

it

to

the

internal

storage

space.

If

this

button

is

not

available,

you

need

to

press

the

[CTRL]

button

to

switch

to

the

button

bar

containing

the

button.

Connect

the

computer

to

view

the

screenshot

of

the

oscilloscope:

Click

the

[MENU]

button

in

the

upper

left

corner

of

the

screen

to

pop

up 4

function

control

bars,

and

then

click

the

fourth

[USB

Connection]

to

enter

the

USB

transmission

interface.

At

this

time,

use

the

standard

Android

USB

If

the

data

cable

is

connected

to

the

computer,

the

removable

disk

can

be

ejected.

You

can

find

the

saved

screenshot

in

the

disk.

Note

that

you

cannot

modify

the

file

name

of

the

image

directly

in

the

disk.

Otherwise,

the

oscilloscope

image

manager

cannot

display

the

image.

Analysis

of

common

problems

1:

Why

can't

I

turn

on

the

phone

after

receiving

it?

A:

Maybe

after

the

final

test

is

completed,

the

tester

forgets

to

shut

down

and

puts

it

in

the

inventory

until

it

runs

out.

After

receiving

the

goods,

it

runs

out

of

power.

Please

use

USB

for

half

an

hour

before

powering

on.

Do

not

use

computer

USB

for

charging.

Computer

USB

If

the

power

is

too

low,

you

will

be

dissatisfied.

Use

the

original

charger.

2:

Why

is

there

no

waveform

in

the

test,

and

there

is

only

one

line

on

the

screen?

Answer:

Please

check

whether

the

pause

has

been

pressed.

If

not,

press

the

[Auto

Adjust]

button

once.

If

not,

it

may

be

that

the

signal

source

does

not

have

a

signal

output,

or

the

probe

wire

is

short-circuited

or

disconnected.

Please

check

with

a

multimeter.

Whether

the

probe

and

signal

source

are

normal

3:

Why

is

the

voltage

value

data

0?

Answer:

Please

adjust

the

vertical

sensitivity

and

time

base

(sampling

rate),

or

press

the

[AUTOSET]

screen

to

display

at

least

a

clear

and

complete

periodic

waveform,

and

the

top

and

bottom

of

the

waveform

should

be

completely

displayed

on

the

screen,

without

cutting

the

top.

Voltage

data

is

correct

4:

Why

is

the

frequency

value

data

0?

Answer:

First

of

all,

you

need

to

make

sure

that

the

trigger

mode

is

Auto.

If

it

is

still

O

in

Auto

mode,

you

need

to

press

the

[AUTOSET]

button

once.

At

least

one

clear

and

complete

periodic

waveform

is

displayed

on

the

screen,

and

the

waveform

is

to

be

triggered.

(The

green

arrow

indicates

that

the

position

is

between

the

top

and

bottom

of

the

waveform.

It

is

fixed

and

does

not

shake.)

The

data

of

the

frequency

value

is

correct.

5:

Why

is

the

duty

cycle

0?

Answer:

First

of

all,

you

need

to

ensure

that

the

trigger

mode

is

Auto.

If

it

is

still

O

in

Auto

mode,

the

trigger

may

not

be

adjusted

between

the

waveforms.

After

the

trigger

line

is

adjusted

between

the

waveforms,

the

waveform

will

be

fixed.

The

duty

cycle

data

is

correct

after

at

least

1

clear

periodic

waveform

is

displayed

6:

Why

are

the

AC

coupled

and

DC

coupled

waveforms

the

same?

Answer:

If

the

input

signal

is

a

symmetrical

AC

signal

(signal

output

by

the

signal

generator),

the

waveform

is

the

same

whether

it

is

AC

coupling

or

DC

coupling.

If

it

is

an

asymmetric

AC

signal

or

a

DC

pulsating

signal,

the

waveform

is

only

when

the

coupling

is

switched.

Will

move

up

and

down

7:

Why

does

the

waveform

jump

up

and

down

when

I

test

the

signal?

Ica

n’

t

see

any

waveform

but

only

see

multiple

lines

jumping

up

and

down?

Answer:

Set

the

trigger

mode

to

Auto,

and

then

press

the

[AUTOSET]

button

once.

If

it

is

not

resolved,

the

probe

on

the

probe

may

not

be

grounded,

or

the

probe

end

of

the

probe

may

be

disconnected.

Please

use

a

multimeter

to

check

whether

the

probe

is

normal.

8:

Why

does

the

waveform

of

the

test

shake

from

side

to

side

and

cannot

be

fixed?

Answer:

You

need

to

adjust

the

trigger

voltage,

that

is,

the

green

arrow

on

the

right.

Press

and

hold

the

green

trigger

arrow

on

the

right

and

move

it

up

and

down.

You

need

to

adjust

the

green

indicator

arrow

between

the

upper

and

lower

waveforms.

The

waveform

is

triggered

and

fixed,

or

you

enter

the

setting.

Menu

turns

on

"Auto

50%"

9:

Why

can't

Il

capture

the

sudden

pulse

waveform

or

digital

logic

signal?

Answer:

Adjust

the

trigger

mode

to

“normal”

or

“single”

,

and

then

adjust

the

trigger

voltage,

time

base,

and

vertical

sensitivity.

10:

Why

is

there

no

waveform

when

measuring

a

battery

or

other

DC

voltage?

Answer:

The

battery

voltage

signal

is

a

stable

DC

signal

and

has

no

curve

waveform.

In

the

DC

coupling

mode,

and

then

adjust

the

vertical

sensitivity,

an

upward

or

downward

offset

straight

line

waveform

will

appear.

If

it

is

AC

coupling,

no

matter

what

No

waveform

adjustment

11:

Why

the

charge

is

not

full?

Answer:

It

may

be

using

a

laptop

or

USB

charging

below

2A.

The

USB

output

power

of

the

laptop

is

too

small

to

be

dissatisfied.

Replace

it

with

an

original

5V2A

charger

and

it

will

be

full.

12:

Why

is

the

waveform

of

the

220V

power

frequency

50Hz

AC

very

stiff?

Answer:

The

oscilloscope

needs

to

display

such

low-frequency

signals

at

50Hz.

The

sampling

rate

needs

to

be

very

low

to

capture

the

50Hz

signal.

The

oscilloscope

will

wait

when

the

sampling

rate

is

low.

Therefore,

it

behaves

as

a

“change

card”

.

All

oscilloscopes

in

the

world

are

measuring

50Hz

signals.

Change

cards

every

time,

not

because

the

oscilloscope

itself

13:

Why

is

the

peak-to-peak

data

of

VPP

below

600V

instead

of

220V

or

310V

when

measuring

the

220V

waveform

of

the

commercial

power?

A:

The

mains

220V

is

a

symmetrical

AC

signal.

The

positive

peak

voltage

(maximum

value)

is

+

310V

and

the

negative

peak

voltage

(minimum

value)

is

-310V.

Therefore,

the

peak-to-peak

value

is

620V.

Click

[Parameter

Display]

to

enter

the

parameter

control

bar

to

open

the

effective

value.

At

this

time,

the

220V

voltage

is

often

said.

The

effective

value

of

the

mains

voltage

fluctuates

between

180

—

260V,

so

the

peak-to-peak

VPP

is

in

the

range

of

507

=

733V.

14:

Why

is

the

measured

mains

220V

waveform

not

a

standard

sine

wave

and

distorted?

Answer:

The

mains

power

grid

is

generally

polluted

and

contains

more

high-order

harmonic

components.

These

harmonics

will

show

a

distorted

sine

when

superim-

posed

on

a

sine

wave.

This

is

a

normal

phenomenon.

Generally,

the

mains

waveform

is

distorted.

Has

nothing

to

do

with

the

oscilloscope

itself

15:

Why

is

the

position

of

the

baseline

(OV)

and

the

left

arrow

(OV)

on

the

screen

different

from

each

other

when

there

is

no

signal

input,

and

there

is

a

large

offset?

A:

Click

the

[MENU]

button

in

the

upper

left

corner

of

the

screen

to

pop

up

4

function

control

bars,

and

then

click

the

first

[System

Settings]

to

pop

up

5

setting

control

bars,

and

then

click

[Baseline

Calibration].

All

probes

need

to

be

pulled

out

first

Charge

with

USB

power,

make

sure

it

is

unplugged,

and

then

click

[OK]

to

calibrate

16:

Why

the

signal

voltage

above

5MHz

is

greatly

attenuated,

and

the

bandwidth

is

only

5MHz?

A:

When

measuring

above

5MHZz,

you

need

to

set

the

probe

to

the

10X

position,

and

the

oscilloscope

must

also

be

set

to

the

10X

input

mode,

because

the

oscilloscope's

probe

line

itself

has

a

capacitance

of

up

to

100

—

300pF,

which

is

a

high-frequency

signal.

Very

large

capacitor!

The

signal

has

been

greatly

attenuated

through

the

probe

to

the

input

of

the

oscilloscope,

and

the

equivalent

bandwidth

is

5MHz.

Therefore,

in

order

to

match

the

hundreds

of

pF

of

the

probe

line,

the

input

of

the

probe

line

is

attenuated

by

10

times

(the

switch

is

in

the

10X

range).

A

few

hundred

pF

capacitors

are

just

used

for

impedance

matching.

At

this

time,

the

bandwidth

is

100MHz.

Note

that

only

100MHz

probes

can

be

used.

17:

Why

does

the

green

charging

indicator

keep

off

when

the

computer

is

on?

A:

The

green

indicator

light

indicates

that

the

charger

is

no

longer

supplying

power.

The

charger

will

continue

to

supply

power

to

the

system

when

the

device

is

powered

on,

so

the

green

indicator

light

will

always

be

on.

When

the

battery

icon

in

the

upper

right

corner

is

fully

green

when

the

device

is

powered

on,

the

battery

is

fully

charged.

Battery

or

DC

voltage

measurement

Gear

selection:

The

battery

voltage

is

generally

below

40V,

and

other

DC

voltages

are

uncertain.

You

need

to

adjust

the

gear

according

to

the

actual

situation.

If

it

is

lower

than

40V,

use

the

1X

gear,

and

if

it

is

higher

than

40V,

use

the

10X

gear

(the

probe

and

oscilloscope

are

set

to

Same

file)

1:

First

set

the

oscilloscope

to

Auto

trigger

mode

(default

is

Auto

trigger

mode

after

power

on),

Auto

trigger

mode

is

used

to

test

the

periodic

signal

(DC

voltage

is

a

periodic

signal)

2:

The

oscilloscope

is

set

to

the

corresponding

position

(the

default

is

1X

position

after

booting)

3:

The

oscilloscope

is

set

to

DC

coupling

mode

4:

Plug

in

the

probe,

and

turn

the

switch

on

the

probe

handle

to

the

corresponding

position

5:

Make

sure

the

battery

has

power

or

DC

voltage

has

voltage

output

6:

Connect

the

probe

clip

to

the

battery

negative

or

DC

negative,

and

the

probe

to

the

battery

or

DC

positive

7:

Press

the

[AUTOSET]

button

once,

the

DC

signal

is

displayed,

and

then

look

at

the

average

value

parameter.

Note

that

the

battery

voltage

or

other

DC

voltages

are

DC

signals,

there

is

no

curve

waveform,

only

a

straight

line

with

up

and

down

offset.

,

And

the

peak-to-peak

and

frequency

of

this

signal

are

both

O

Crystal

measurement

Gear

selection:

It

is

easy

to

stop

the

oscillation

after

the

crystal

meets

the

capacitor.

The

input

capacitance

of

the

1X

probe

is

up

to

100

—

300pF,

the

10X

gear

is

about

10

—

30pF,

and

the

1X

gear

is

easy

to

stop

the

vibration,

so

it

needs

to

be

set

to

the

10X

gear,

that

is,

Both

the

probe

and

the

oscilloscope

should

be

switched

to

the

10X

position

(the

probe

and

the

oscilloscope

are

both

set

to

the

10X

position)

1:

First

set

the

oscilloscope

to

Auto

trigger

mode

(default

is

Auto

trigger

mode

after

power

on),

Auto

trigger

mode

is

used

to

test

the

periodic

signal

(the

crystal

resonance

sinusoidal

signal

belongs

to

the

periodic

signal)

2:

The

oscilloscope

is

set

to

the

10X

position

(the

default

is

1X

position

after

booting)

3:

The

oscilloscope

is

set

to

AC

coupling

mode

4:

Plug

in

the

probe

and

turn

the

switch

on

the

probe

handle

to

the

10X

position

5:

Make

sure

the

crystal

motherboard

is

powered

on

and

running

6:

Connect

the

probe

clip

to

the

ground

of

the

crystal

oscillator

main

board

(the

negative

end

of

the

power

supply),

pull

out

the

probe

cap,

the

needle

tip

inside,

and

touch

the

needle

tip

to

one

of

the

pins

of

the

crystal

7:

Press

the

[AUTOSET]

button

once,

the

waveform

of

the

crystal

to

be

measured

is

displayed.

If

the

waveform

after

the

automatic

adjustment

is

too

small

or

too

large,

you

can

press

[CTRL]

to

switch

to

the

zoom

button

bar,

press

[V+]

and

[V-]

Manually

adjust

the

waveform

size

PWM

signal

measurement

of

MOS

tube

or

IGBT

Gear

selection:

The

voltage

of

the

PWM

signal

that

directly

drives

the

MOS

tube

or

IGBT

is

generally

within

10V

—

20V,

and

the

PWM

pre-stage

control

signal

is

also

generally

within

3

»

20V.

The

1X

gear

can

test

up

to

40V,

so

the

1X

gear

is

sufficient

for

testing

the

PWM

signal.

(The

probe

and

oscilloscope

are

set

to

1X).

1:

First

set

the

oscilloscope

to

Auto

trigger

mode

(default

is

Auto

trigger

mode

after

power

on),

Auto

trigger

mode

is

used

to

test

the

periodic

signal

(PWM

belongs

to

periodic

signal)

2:

The

oscilloscope

is

set

to

the

1X

position

(the

default

is

1X

position

after

booting)

3:

The

oscilloscope

is

set

to

DC

coupling

mode

4:

Plug

in

the

probe

and

turn

the

switch

on

the

probe

handle

to

the

1X

position

5:

Make

sure

that

the

PWM

motherboard

has

a

PWM

signal

output

at

this

time

6:

Connect

the

probe

clip

to

the

S

pole

of

the

MOS

tube

and

the

probe

to

the

G

pole

of

the

MOS

tube

7:

Press

the

[AUTOSET]

button

once,

the

measured

PWM

waveform

is

displayed.

If

the

waveform

after

the

automatic

adjustment

is

too

small

or

too

large,

you

can

press

[CTRL]

to

switch

to

the

zoom

button

bar,

press

[V+]

and

[V-]

Manually

adjust

the

waveform

size

Signal

generator

output

measurement

Gear

selection:

The

output

voltage

of

the

signal

generator

is

within

30V,

and

the

maximum

test

of

1V

is

40V,

so

it

is

sufficient

to

test

the

output

of

the

signal

generator

with

1X

(the

probe

and

oscilloscope

are

set

to

1X).

1:

First

set

the

oscilloscope

to

Auto

trigger

mode

(default

is

Auto

trigger

mode

after

power

on),

Auto

trigger

mode

is

used

to

test

the

periodic

signal

(the

signal

output

by

the

signal

generator

belongs

to

the

periodic

signal)

2:

The

oscilloscope

is

set

to

the

1X

position

(the

default

is

1X

position

after

booting)

3:

The

oscilloscope

is

set

to

DC

coupling

mode

4:

Plug

in

the

probe

and

turn

the

switch

on

the

probe

handle

to

the

1X

position

5:

Make

sure

the

signal

generator

is

turned

on

and

outputting

signals

6:

Connect

the

probe

clip

to

the

black

clip

of

the

signal

generator

output

cable,

and

connect

the

probe

to

the

red

output

cable

of

the

signal

generator

7:

Press

the

[AUTOSET]

button

once,

and

the

waveform

output

by

the

generator

is

displayed.

If

the

waveform

after

the

automatic

adjustment

is

too

small

or

too

large,

you

can

press

[CTRL]

to

switch

to

the

zoom

button

bar,

press

[V+]

and

[V-]

Manually

adjust

the

waveform

size

220V

or

110V

household

mains

measurement

Gear

selection:

household

electricity

is

generally

180

—

260V,

peak-to-peak

voltage

is

507

=

733V,

1X

file

can

measure

up

to

40V,

10X

file

can

measure

up

to

400V,

100X

file

can

measure

up

to

4000V,

the

default

standard

probe

is

10X

high

voltage

probe,

the

highest

can

only

be

Measure

400V

peak-to-peak,

so

you

need

to

prepare

your

own

100X

probe,

and

then

set

it

to

100X,

that

is,

the

probe

and

oscilloscope

must

be

switched

to

100X.

1:

First

set

the

oscilloscope

to

Auto

trigger

mode

(default

is

Auto

trigger

mode

after

power

on),

Auto

trigger

mode

is

used

to

test

the

periodic

signal

(5OHz

of

household

electricity

is

a

periodic

signal)

2:

The

oscilloscope

is

set

to

the

100X

position

(the

default

is

1X

position

after

booting)

3:

The

oscilloscope

is

set

to

AC

coupling

mode

4:

Plug

in

the

probe

and

turn

the

switch

on

the

probe

handle

to

the

100X

position

5:

Ensure

that

the

tested

end

has

household

electrical

output

6:

Connect

the

probe

clip

and

the

probe

to

the

2

wires

of

household

electricity,

without

distinguishing

the

positive

and

negative

poles.

7:

Press

the

[AUTOSET]

button

once,

and

the

waveform

of

household

electricity

is

displayed.

If

the

waveform

after

the

automatic

adjustment

is

too

small

or

too

large,

you

can

press

[CTRL]

to

switch

to

the

zoom

button

bar,

press

[V+]

and

[V-]

Manually

adjust

the

waveform

size

Power

ripple

measurement

Gear

selection:

If

the

output

voltage

of

the

power

supply

is

below

40V,

set

it

to

1X

(the

probe

and

oscilloscope

are

set

to

1X),

if

it

is

40

—

400V,

you

need

to

set

to

10X

(the

probe

and

oscilloscope

are

set

to

the

same

file)

)

1:

First

set

the

oscilloscope

to

Auto

trigger

mode

(default

is

Auto

trigger

mode

after

power

on),

Auto

trigger

mode

is

used

to

test

the

periodic

signal

(DC

voltage

is

a

periodic

signal)

2:

The

oscilloscope

is

set

to

the

corresponding

position

(the

default

is

1X

position

after

booting)

3:

The

oscilloscope

is

set

to

the

AC

coupling

mode.

Note

that

the

AC

coupling

mode

is

AC.

4:

Plug

in

the

probe,

and

turn

the

switch

on

the

probe

handle

to

the

corresponding

position

5:

Make

sure

the

power

is

on

and

there

is

voltage

output

6:

Connect

the

probe

clip

to

the

negative

terminal

of

the

power

output,

connect

the

probe

to

the

positive

terminal

of

the

power

output,

and

wait

for

about

3

seconds.

End

the

waiting

when

the

yellow

line

is

flush

with

the

left

yellow

arrow

7:

Press

the

[AUTOSET]

button

once,

and

the

power

ripple

is

displayed.

Inverter

output

measurement

Gear

selection:

The

inverter

output

voltage

is

similar

to

that

of

household

electricity.

The

peak-to-peak

voltage

is

above

500V.

The

1X

file

can

measure

up

to

40V,

the

10X

file

can

measure

up

to

400V,

and

the

100X

file

can

measure

up

to

4000V.

The

default

standard

probe

is

10X

high

voltage

probe.

It

can

only

measure

400V

peak-to-peak

value,

so

you

need

to

prepare

your

own

100X

probe,

and

then

set

it

to

the

100X

position,

that

is,

the

probe

and

the

oscilloscope

must

be

switched

to

the

100X

position.

1:

First

set

the

oscilloscope

to

Auto

trigger

mode

(default

is

Auto

trigger

mode

after

power

on),

Auto

trigger

mode

is

used

to

test

the

periodic

signal

(the

signal

output

by

the

inverter

belongs

to

the

periodic

signal)

2:

The

oscilloscope

is

set

to

the

100X

position

(the

default

is

1X

position

after

booting)

3:

The

oscilloscope

is

set

to

DC

coupling

mode

4:

Plug

in

the

probe

and

turn

the

switch

on

the

probe

handle

to

the

100X

position

5:

Make

sure

the

inverter

is

powered

on

and

has

voltage

output

6:

Connect

the

probe

clip

and

probe

to

the

output

of

the

inverter

without

distinguish-

ing

between

positive

and

negative

poles

7:

Press

the

[AUTOSET]

button

once,

the

waveform

of

the

inverter

is

displayed.

If

the

waveform

after

the

automatic

adjustment

is

too

small

or

too

large,

you

can

press

[CTRL]

to

switch

to

the

zoom

button

bar,

press

[V+]

and

[V-]

Manually

adjust

the

waveform

size

Amplifier

or

audio

signal

measurement

Gear

selection:

The

output

voltage

of

the

power

amplifier

is

generally

below

40V,

and

the

1X

gear

can

test

up

to

40V,

so

the

1X

gear

is

sufficient

(the

probe

and

oscilloscope

are

set

to

1X

gear).

1:

First

set

the

oscilloscope

to

Auto

trigger

mode

(default

is

Auto

trigger

mode

after

power

on)

2:

The

oscilloscope

is

set

to

the

1X

position

(the

default

is

1X

position

after

booting)

3:

The

oscilloscope

is

set

to

AC

coupling

mode

4:

Plug

in

the

probe

and

turn

the

switch

on

the

probe

handle

to

the

1X

position

5:

Make

sure

the

amplifier

is

turned

on

and

is

outputting

audio

signals

6:

Connect

the

probe

clip

and

the

probe

to

the

two

wire

output

ends

of

the

amplifier

without

distinguishing

the

positive

and

negative

poles.

7:

Press

the

[AUTOSET]

button

once,

the

waveform

of

the

inverter

is

displayed.

If

the

waveform

after

the

automatic

adjustment

is

too

small

or

too

large,

you

can

press

[CTRL]

to

switch

to

the

zoom

button

bar,

press

[V+]

and

[V-]

Manually

adjust

the

waveform

size

Automotive

communication

signal

/

bus

signal

measurement

Gear

selection:

Automotive

communication

signals

are

generally

lower

than

20V,

and

1X

gear

can