USING LANYARDS ACTLC5, ACTLS22

Note: Always properly tie the knot made using the stopper on the cord.

3- CHOOSING THE ANCHOR POINT:·

ŸThis may be a tool attachment ring on the user's belt, harness, etc.

ŸIt may be a removable 'D' ring that can be installed on a harness, belt, etc.

Once the anchor point and the lanyard are selected, the connections can

be made using aluminium connector.

ŸItem ACTLC5 is installed on the user's wrist, so the wrist serves as the

anchor point!

ŸAlways make sure the hook-and-loop closures fasten properly, because

they make sure the bracelet stays closed and holds if the tool is

dropped.

Always make sure the carabiners are closed and locked (screwed in).

3

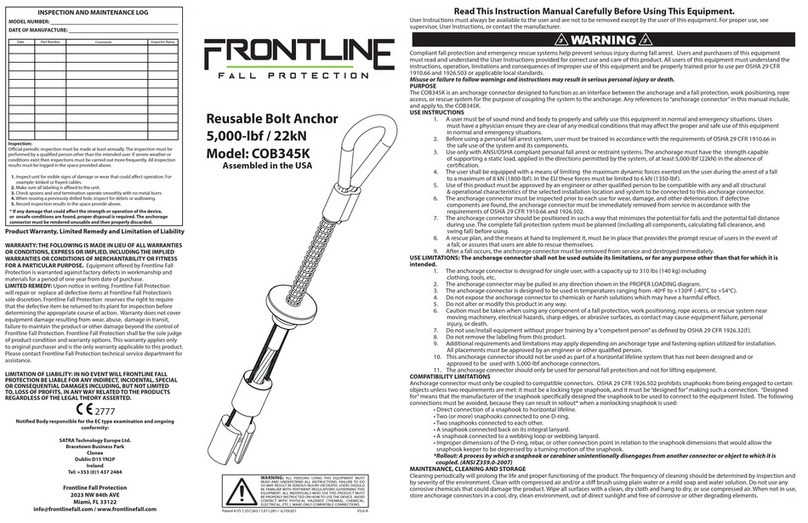

MAXIMUM ALLOWABLE LOADS :

After use, clean your Tool Lanyards accessories and

keep them away from light, any source of heat,

moisture, solvents, and any sharp edges that might

affect their performance.

INSPECTION:

A visual inspection is essential before any use of the Tool Lanyards accessories.

Ÿ Before each use of your Tool Lanyards accessories, make sure they show no signs of cuts, wear, discolouration,

deformation, corrosion, etc. When in doubt, they should be replaced.

Ÿ Do not use Tool Lanyards accessories beyond their weight limit.

Ÿ Always check the connection to the tool before each use.

Ÿ Tool Lanyards that have been used to arrest a falling tool should be taken out of service.

Reference Max. Allowable Load

ACTLS22 10 lbs

ACTLC5

22 lbs

4.4 lbs when used with

self merging tape

HOW TO DISPOSE A TOOL LANYARD:

When the tool lanyard becomes unfit or in case of any wear and tear, dispose it immediately.

FOLLOW THE STEPS FOR DISPOSAL:

ŸMake the three plastic crates namely- Textile, Metal & Plastic for placing the respective components of the tool lanyard.

ŸSpread the tool lanyard on a table / flat surface.

ŸInspect the wear & tear present on the tool lanyard.

ŸIf any wear and tear is observed, dispose the lanyard using a sharp scissors; first cut the Textile and dismantle the tool

lanyard.

ŸPut the Textile, Plastic & Metal components in their respective plastic crates.

DISCLAIMER:

This information on the product is based upon technical data that Frontline obtained under laboratory conditions and believes

to be reliable. Frontline does not guarantee results and take no liability or obligation in connection with this information. As

conditions of end use are beyond our control it is the user's responsibility to determine the hazard levels and the use of proper

personal protective equipment. Persons having technical expertise should undertake evaluation under their own specific

end-use conditions, at their own discretion and risk. Please ensure that this information is only used to check that the

product selected is suitable for the intended use. Any product that is damaged, torn worn or punctured should be

discontinued from usage immediately.

4

WARNING! Whatever combination you use, make sure that it does not interfere with the safe use of your tool.