OEC 9800 Installation Procedure

1

Contents

Overview.........................................................................................................................................................................3

Unpacking the System ..................................................................................................................................................3

Depalletization Performed By .......................................................................................................................................4

Installation Report .........................................................................................................................................................5

C-Arm Damage Inspection ...........................................................................................................................................5

Workstation Damage Inspection...................................................................................................................................5

Inventory of Customer Items.........................................................................................................................................6

C-Arm Items ..............................................................................................................................................................6

Workstation Items......................................................................................................................................................6

Optional Equipment...................................................................................................................................................6

Installation Procedures .................................................................................................................................................6

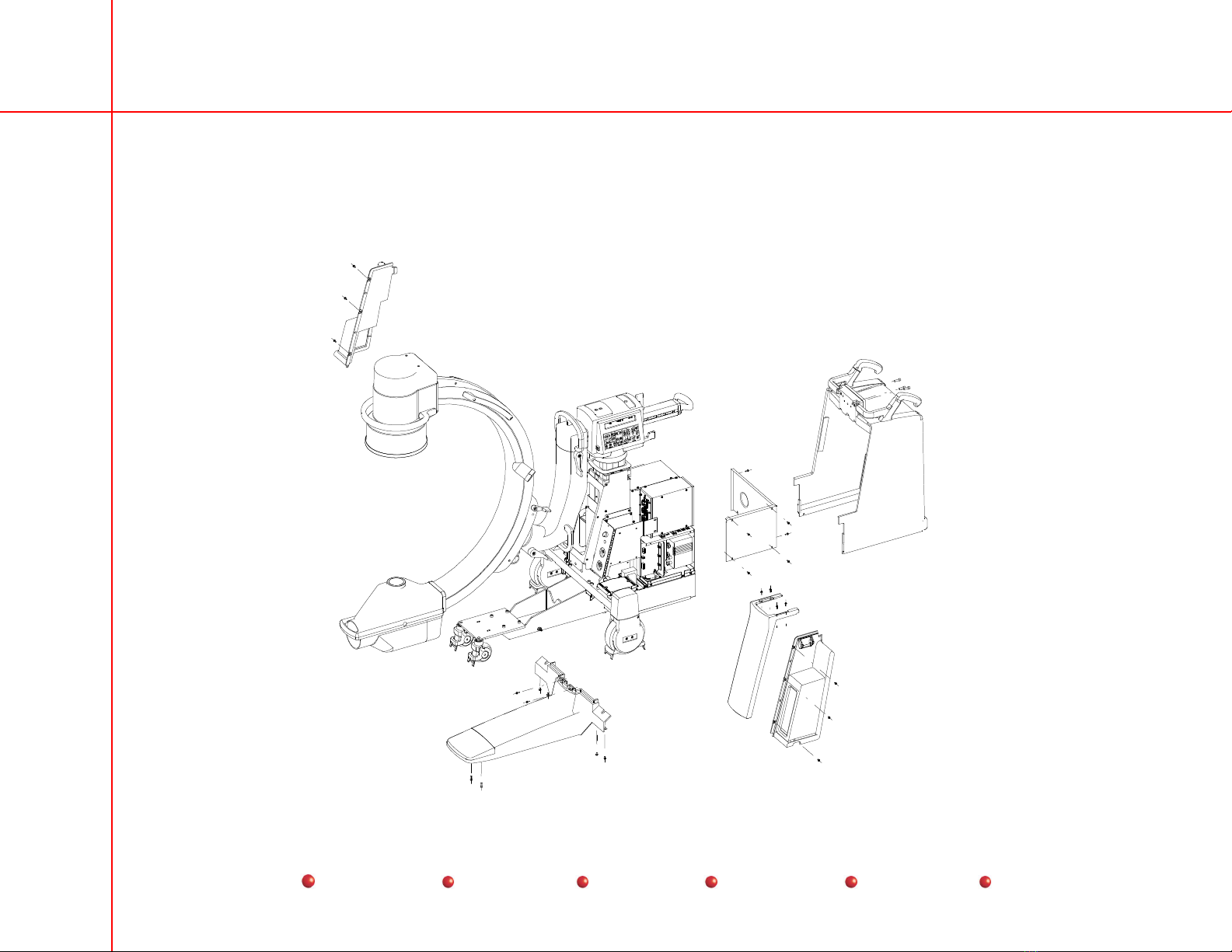

Cover Removal, Internal & Cable Inspection, Partial Setup..........................................................................................7

Mechanical Checks.....................................................................................................................................................10

The Power Cord Assembly .........................................................................................................................................10

Isolation Transformer Strapping .................................................................................................................................12

Power ON System ......................................................................................................................................................16

Line Voltage Regulation..............................................................................................................................................20

C-Arm Control Panel and Foot/handswitch Check .....................................................................................................21

Workstation Keyboard Check .....................................................................................................................................24

Backup the Configuration Files...................................................................................................................................25

Options .......................................................................................................................................................................26

Cine Archive Disk Test ............................................................................................................................................26

High Capacity Disk Test ..........................................................................................................................................26

VCR Test.................................................................................................................................................................26

IR Transmitter Test..................................................................................................................................................26

Digital Hardcopy Camera test..................................................................................................................................27

Instant Film/Paper (Onboard) Printer.......................................................................................................................27

Thermal Printer Test................................................................................................................................................27