Druck DPI 150 User Manual

1 K344 Issue No. 2

Introduction

The Druck DPI 150 high accuracy, single-range pressure indicator uses the

Druck IDOS sensor to produce pressure readings in units of pressure

measurement and aeronautical units.

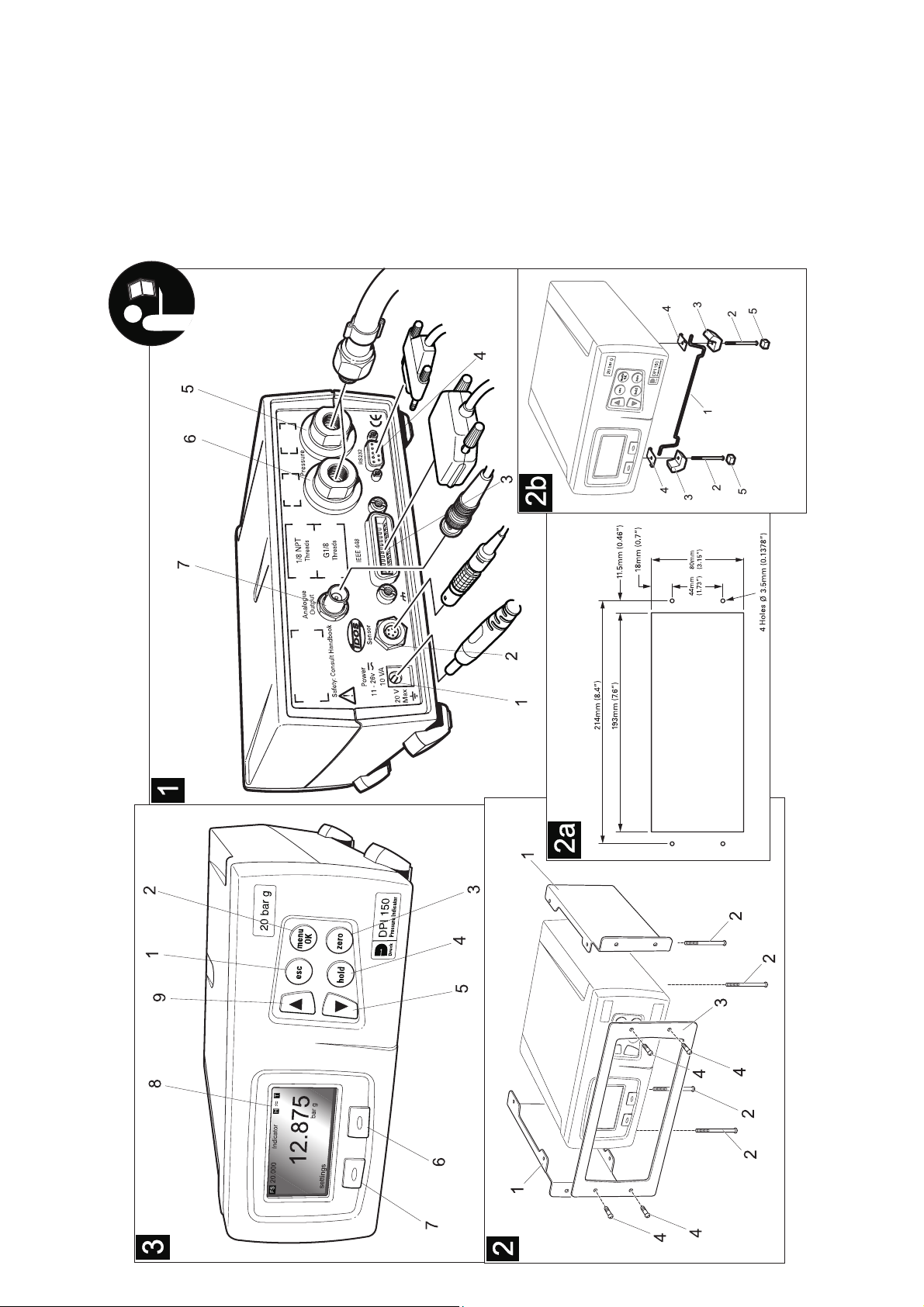

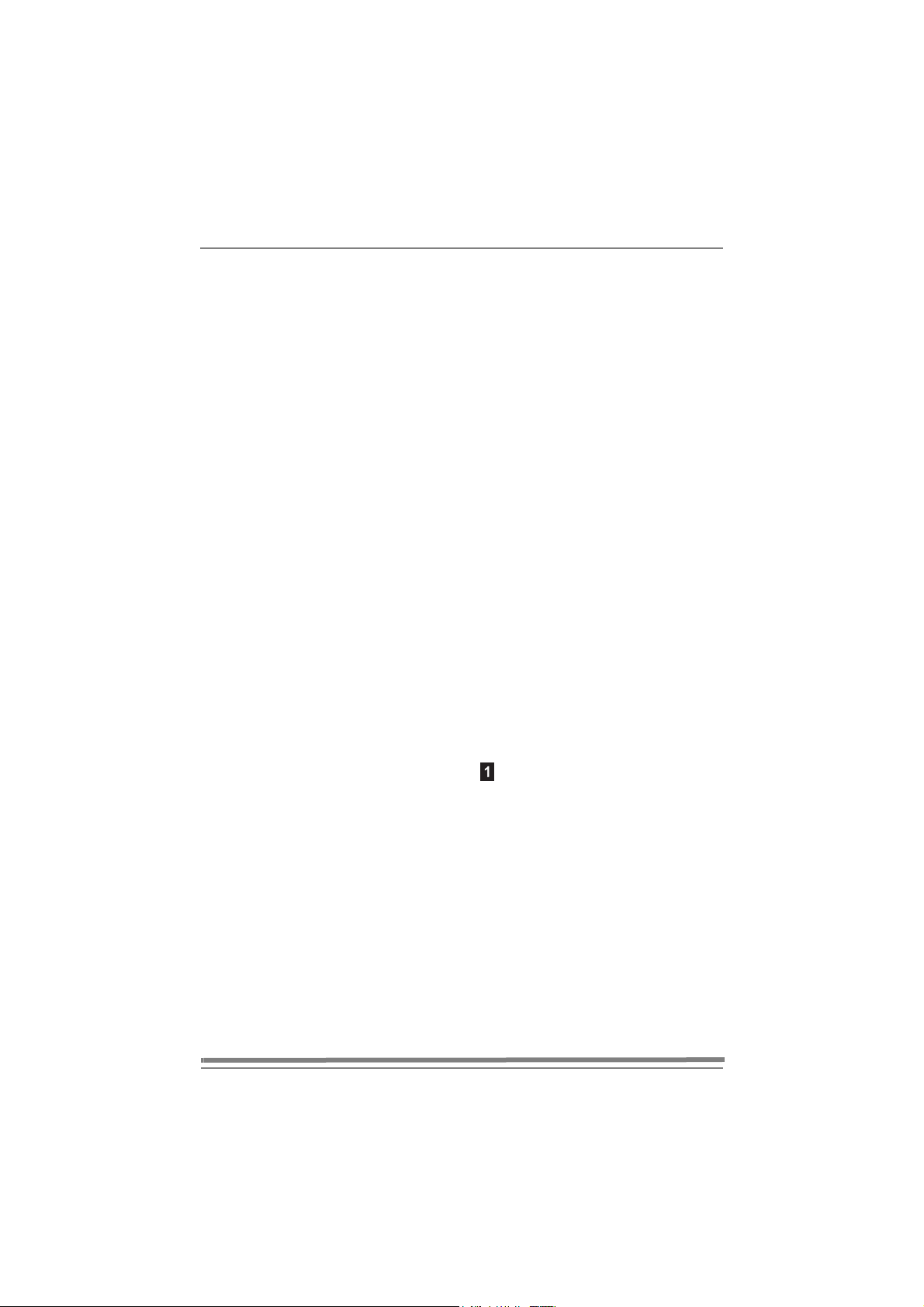

The instrument is contained in a moulded plastic case with integral rubber

feet for workbench surface use. Function keys, on the front panel, allow the

user to access an operating menu and set-up menu. Two more menus,

supervisor and calibration, allow the user to change the PIN codes,

communications settings and display language and for calibration of the

pressure sensor. A four digit PIN code protects both these facilities. The

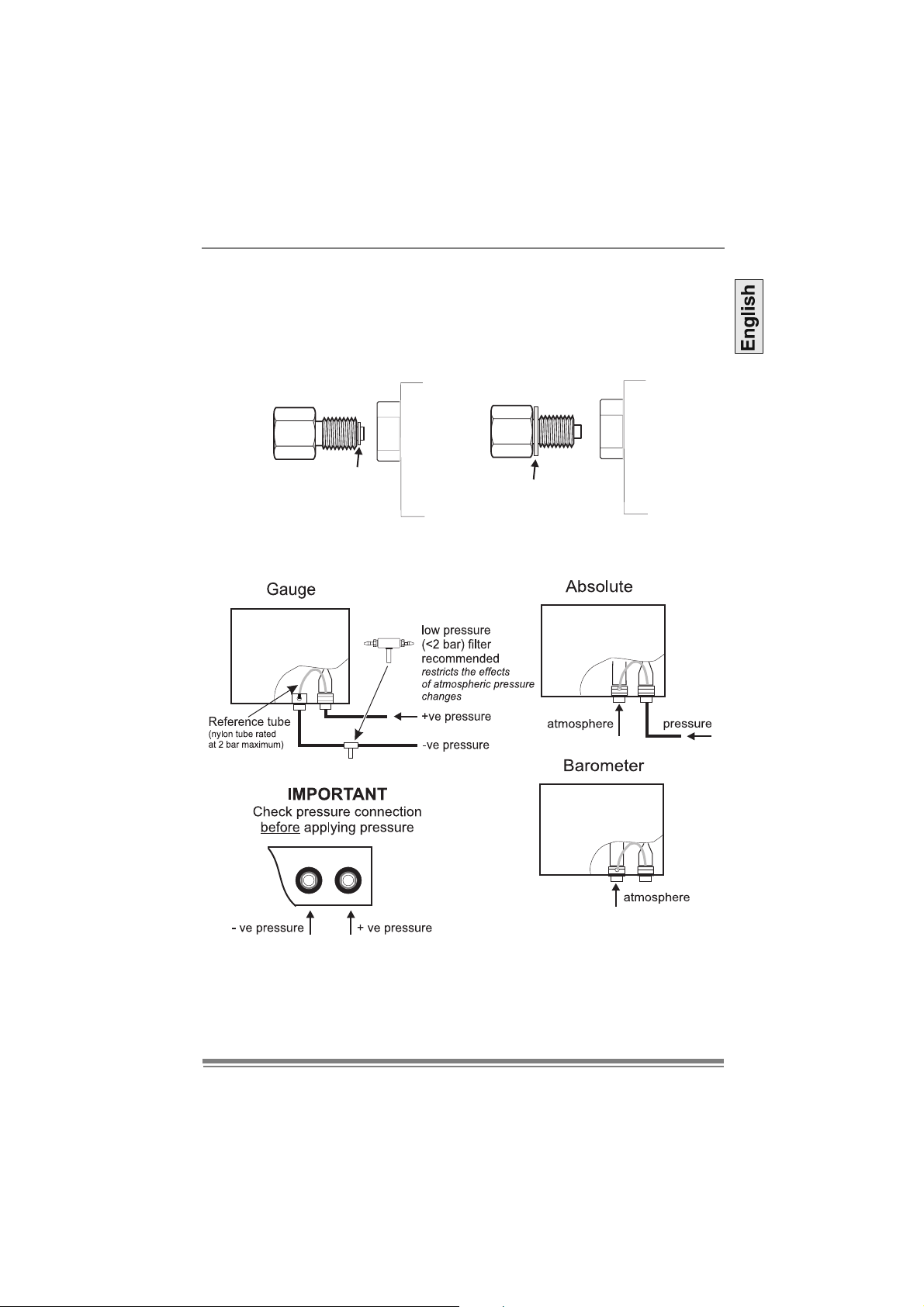

electrical and pressure connections are located on the rear panel.

The instrument is supplied, as standard, with a RS232 data interface. Options

available include an IEEE 488 interface, an analogue output, a barometric

reference, negative calibration, external sensor and panel mount kit.

Specification

Conformity

Safety ...................................................................................... EN61010

EMC emission ......................................................................... EN61326

EMC immunity......................................................................... EN61326

Gauge pressure ranges

....................................................................25, 70, 200, 350, 700 mbar

........................................1, 2, 3.5, 7, 10, 35, 70, 100, 135 and 200 bar

Absolute pressure ranges (using option E, barometric reference)

..................... add atmospheric pressure to the above gauge pressures

Maximum working pressure

0 to 350 mbar .................................................................. 2.0 x full-scale

0.7 to 2 bar, 3.5 to 70 bar, >100 bar ............................... 1.2 x full-scale

Precision

(includes non-linearity, hysteresis, repeatability and temperature effect between

18°C and 28°C [65° to 82°F]

below 1 bar....................................................................0.03% full-scale

1 bar to 200 bar.............................................................0.01% full-scale

Stability below 1 bar ............................................0.02% of reading/year

Stability above 1 bar............................................0.01% of reading/year

Option E, barometric reference

Pressure range .............................................. 750 to 1150 mbar absolute

Precision ................................................................................0.15 mbar

Accuracy

(includes non-linearity, hysteresis, repeatability and temperature effect

between 5°C and 50°C [41° to 120°F]

Stability...........................................................................0.15 mbar/year

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176

FAX 781.665.0780 - TestEquipmentDepot.com