1 K0317 Issue No. 3

UPS III Loop Calibrator

Introduction

The Druck UPS III Series of loop calibrators can supply power

(source mode) and produce readings (measure mode) to

perform field calibrations on 2-wire devices. The set-up menu

enables the user to “source” or “measure” in either voltage or

current and to perform continuity tests. These user

instructions include the operation, safety instructions and

installation requirements for the loop calibrator.

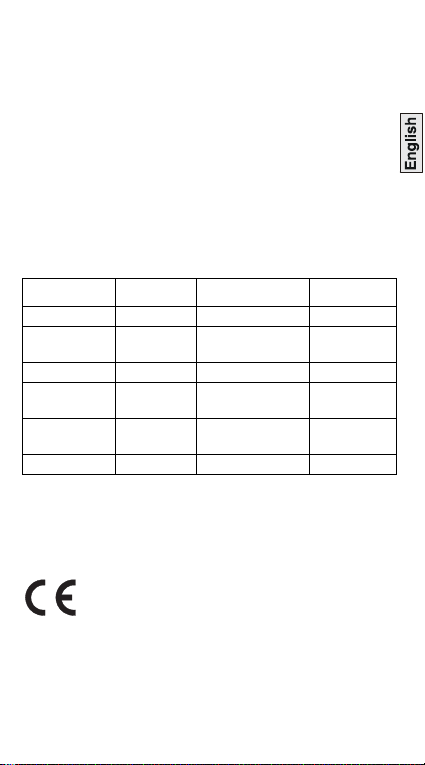

Specifications

Accuracy

Values in table below includes temperature effects 17°C to 27°C

Outside these limits .................. 0.003%/°C(0.0015%/°F)

Calibration Reference................ 22°C ±1°C/RH45%±15%

*Resolution 0.001 lsd least significant digits

** Audio + visual rdg reading

Hart® communications...............menu selectable 220

Ω

loop resistor

Operating Temperature...... -10°C to 50°C (-14°F to 122°F)

Storage Temperature......... -20°C to 70°C (-4°F to 158°F)

This loop calibrator meets the essential protection

requirements of the relevant EEC directives.

Conforms to......... EN61010, EN 61326-1(1997)+ A1(1998)

Electrical Power Supply

.................................... 4 x 1.5 V alkaline size AA or

Universal power supply {see accessories}

Mode Range Accuracy Remarks

Source mA 0 to 24 mA* 0.01% rdg + 2 lsd V-max. 75V

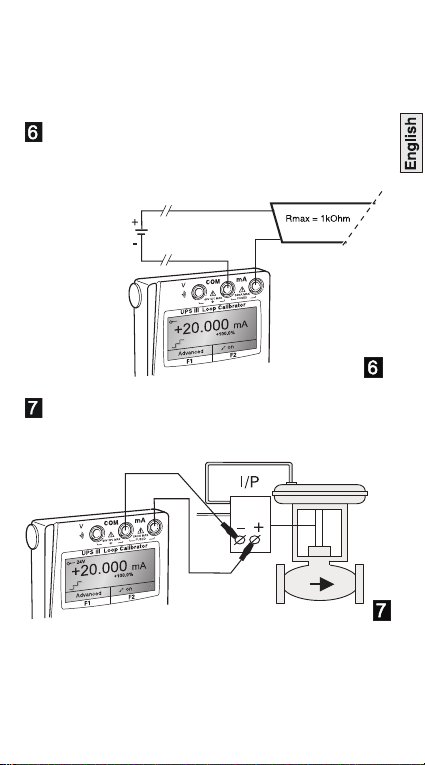

Source mA +

24V 0 to 24 mA*0.01% rdg + 2 lsd R-max 1k

Ω

at 20 mA

Measure mA 0 to 24 mA*0.01% rdg + 2 lsd V-max. 75V

Measure mA

+ 24V 0 to 24 mA*0.01% rdg + 2 lsd R-measure

15

Ω

Measure V 0 to 60V* 0.02% rdg + 4 lsd R-measure

1M

Ω

Continuity <100Ω ** -1mA