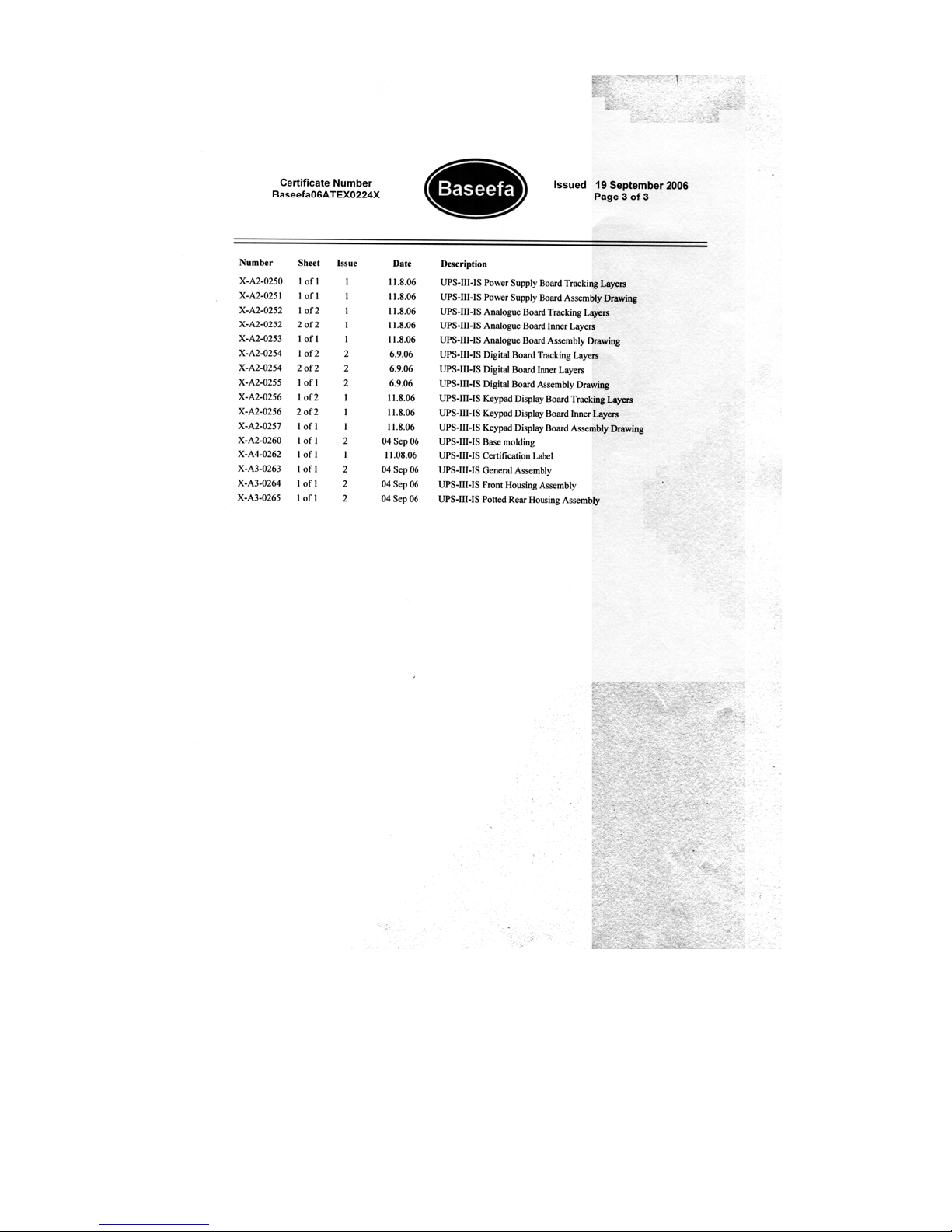

K0341 Issue No. 2 2

Declaration Requirements

The Intrinsically Safe UPS-III is designed and manufactured to meet the

essential health and safety requirements not covered by EC Type

Examination Certificate

Baseefa06

ATEX0224 when installed as detailed

above.

This intrinsically safe loop calibrator is designed and manufactured to

protect against other hazards as defined in paragraph 1.2.7 of Annex II of

the ATEX Directive 94/9/EC.

Specifications

Accuracies

1 year for 17°C to 27°C outside these limits

...................................................................... 0.003%/°C(0.0015%/F°)

Reference.................................................. 22°C ±5°C/RH45%±15%

*R max 650

Ω

at 20 mA lsd least significant digits

** R-measure >1M

Ω

rdg reading

*** Audio + visual

†maximum 24V, typically 21V

Hart® communications................menu selectable 220

Ω

loop resistor

Operating Temperature..................... -10°C to 40°C (14°F to 104°F)

Storage Temperature.............................-20°C to 70°C (-4°F to 158°F)

This loop calibrator meets the essential protection

requirements of the relevant EEC directives.

Electrical Power Supply

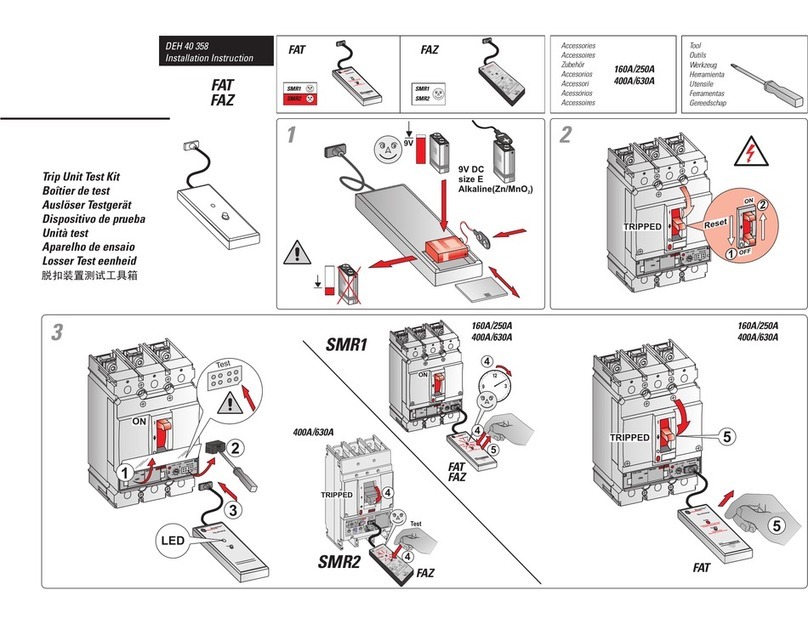

Only use 4 x LR6 (size AA), Duracell PROCELL, Duracell PLUS,

ENERGIZER ULTIMATE or GP SUPERALKALINE LR6.

Physical

Dimensions....................................90 x 140 x 42 mm(3.5” x 5.5” x 1.7”)

Weight (nominal)........................................................460 grams (16.2 oz.)

Terminals ................................................................................ 4 mm sockets

Case ................................................................................ High impact ABS

Environmental............................................................................................ IP40

Relative Humidity........................................................................... 0 to 90%

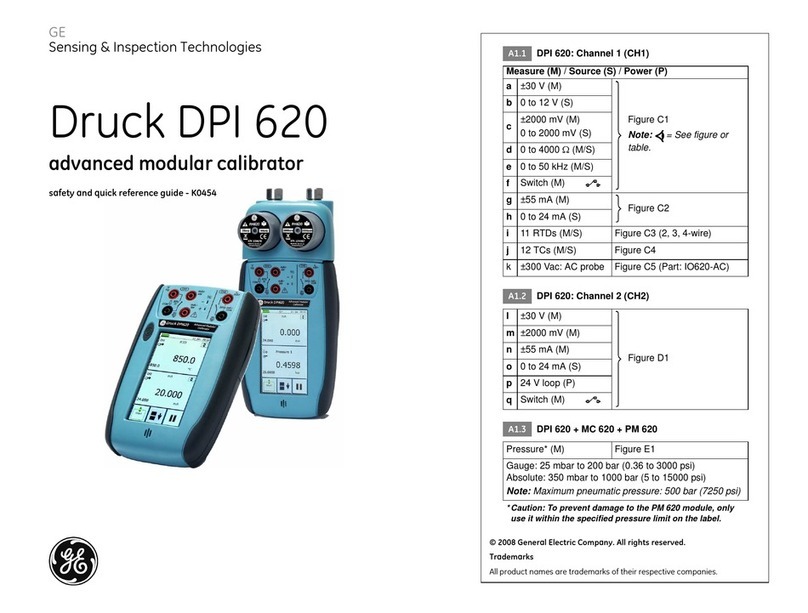

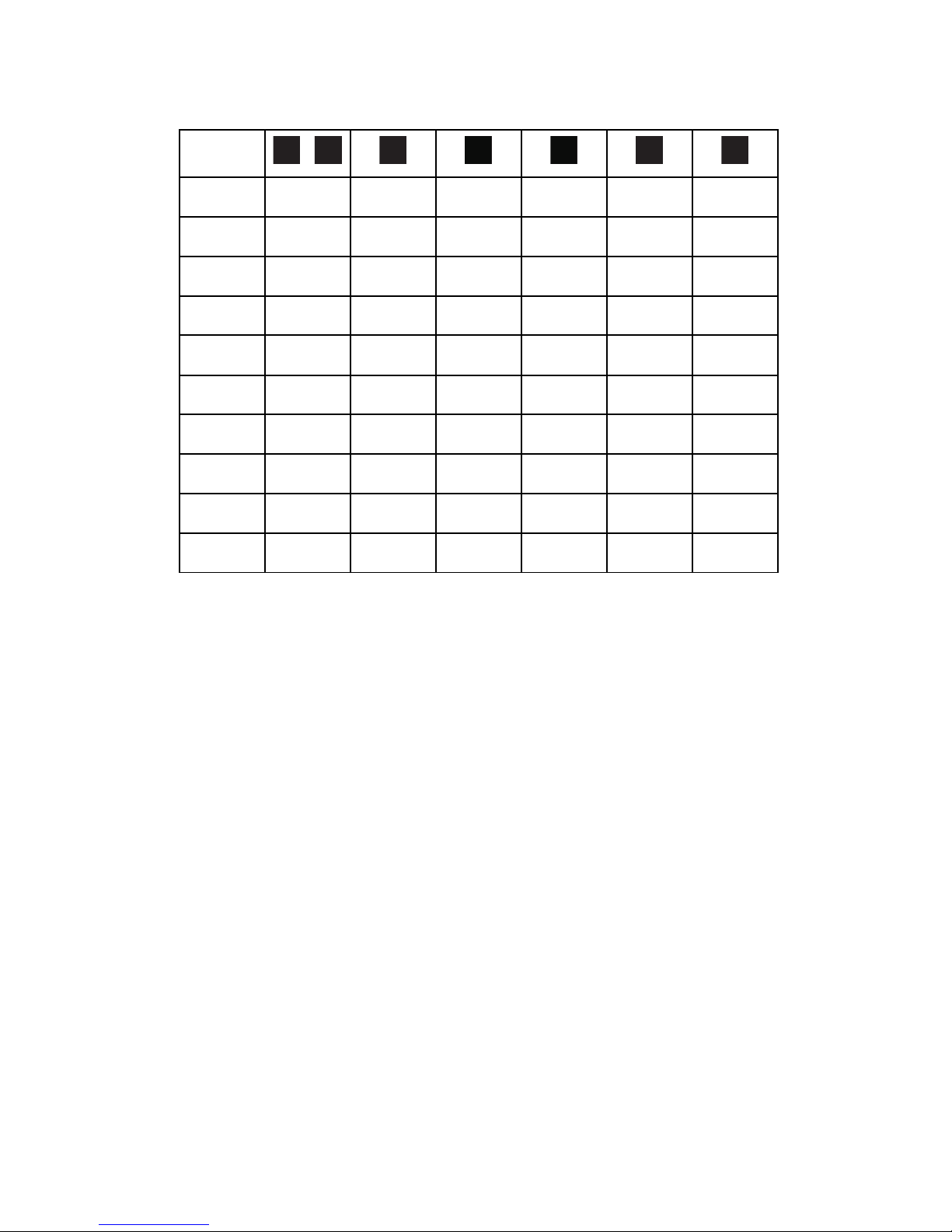

Mode Range Resolution Accuracy

Source 2 wire† 0 to 24 mA 0.001 0.015% rdg + 2 lsd

Source mA 0 to 24 mA*0.001 0.015% rdg + 2 lsd

Measure mA 0 to 24 mA 0.001 0.015% rdg + 2 lsd

Measure V 0 to 50V** 0.01 0.015% rdg + 4 lsd

Continuity <100Ω*** -0.5mA