Order No. 2104 ..

Table of Contents

Product definition1 4.................................................................................................................

Product catalogue1.1 4...........................................................................................................

Function1.2 4..........................................................................................................................

Mounting, electrical connection and operation2 6.................................................................

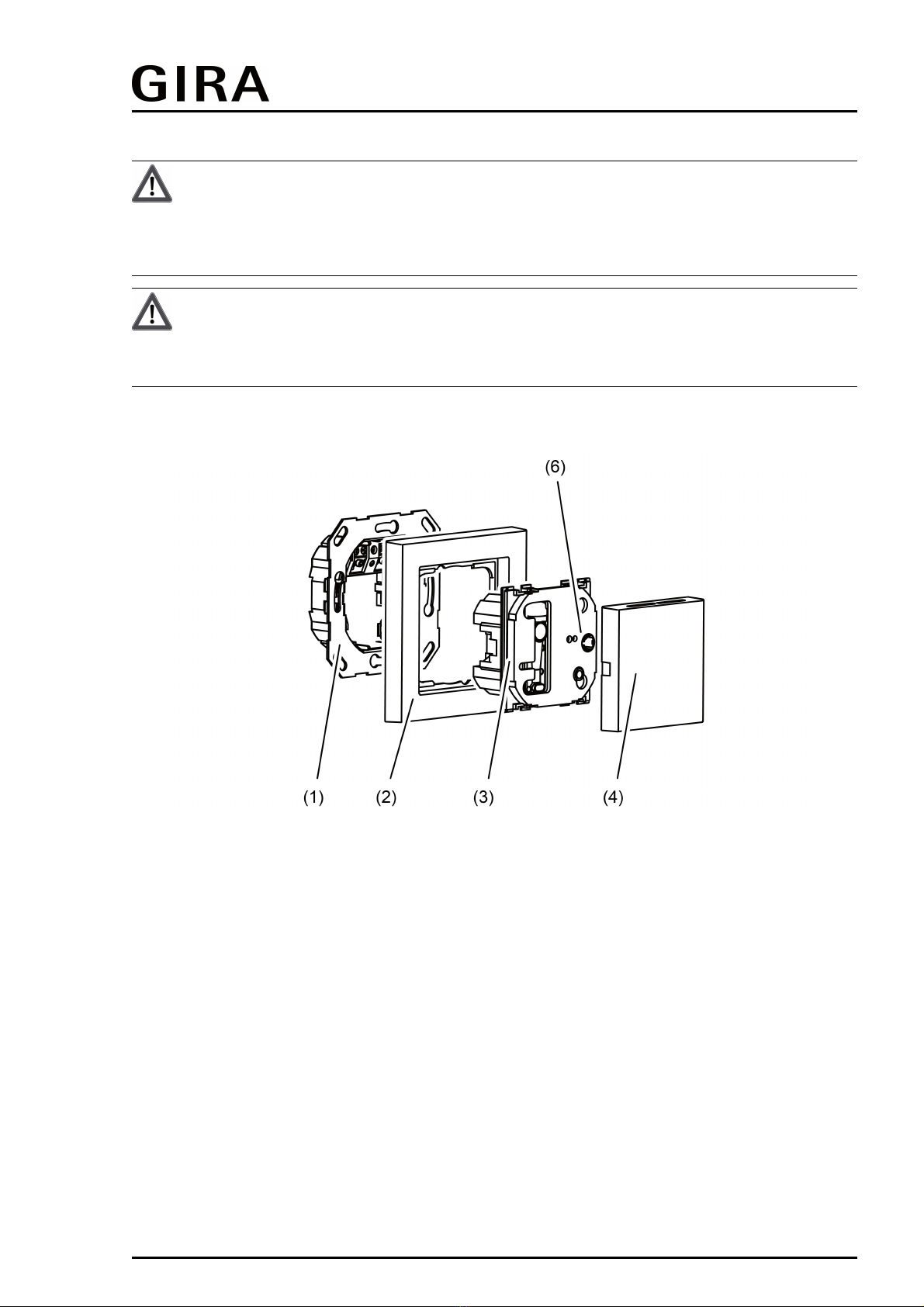

Safety instructions2.1 6...........................................................................................................

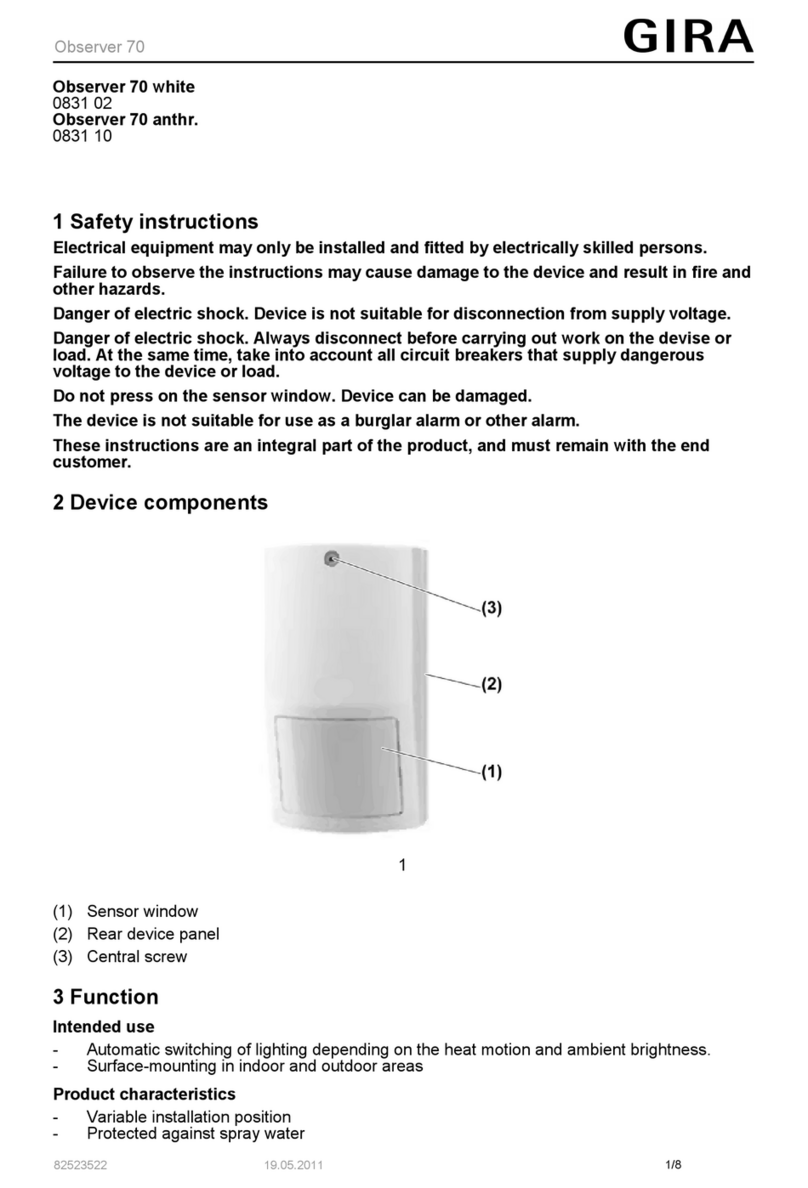

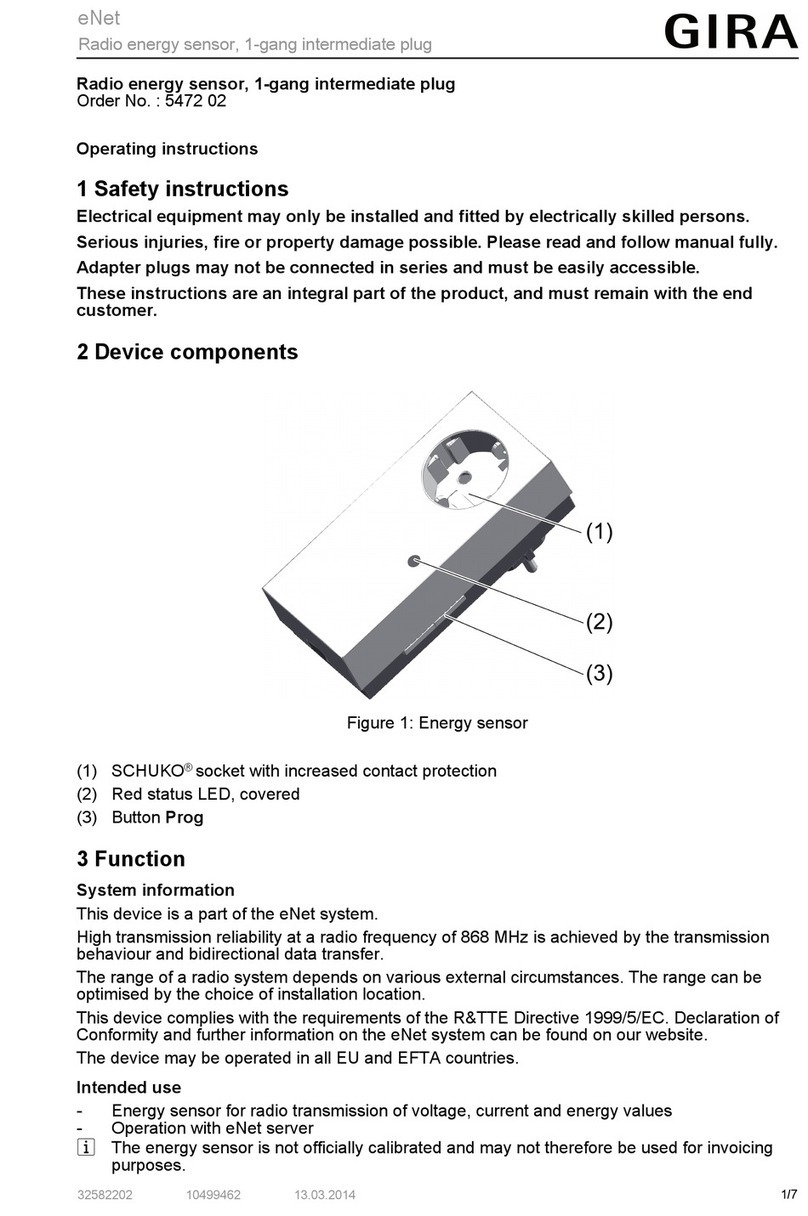

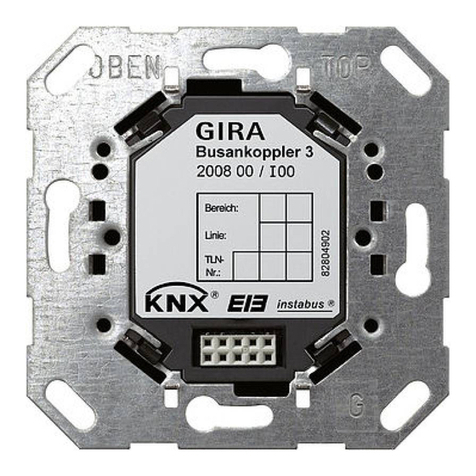

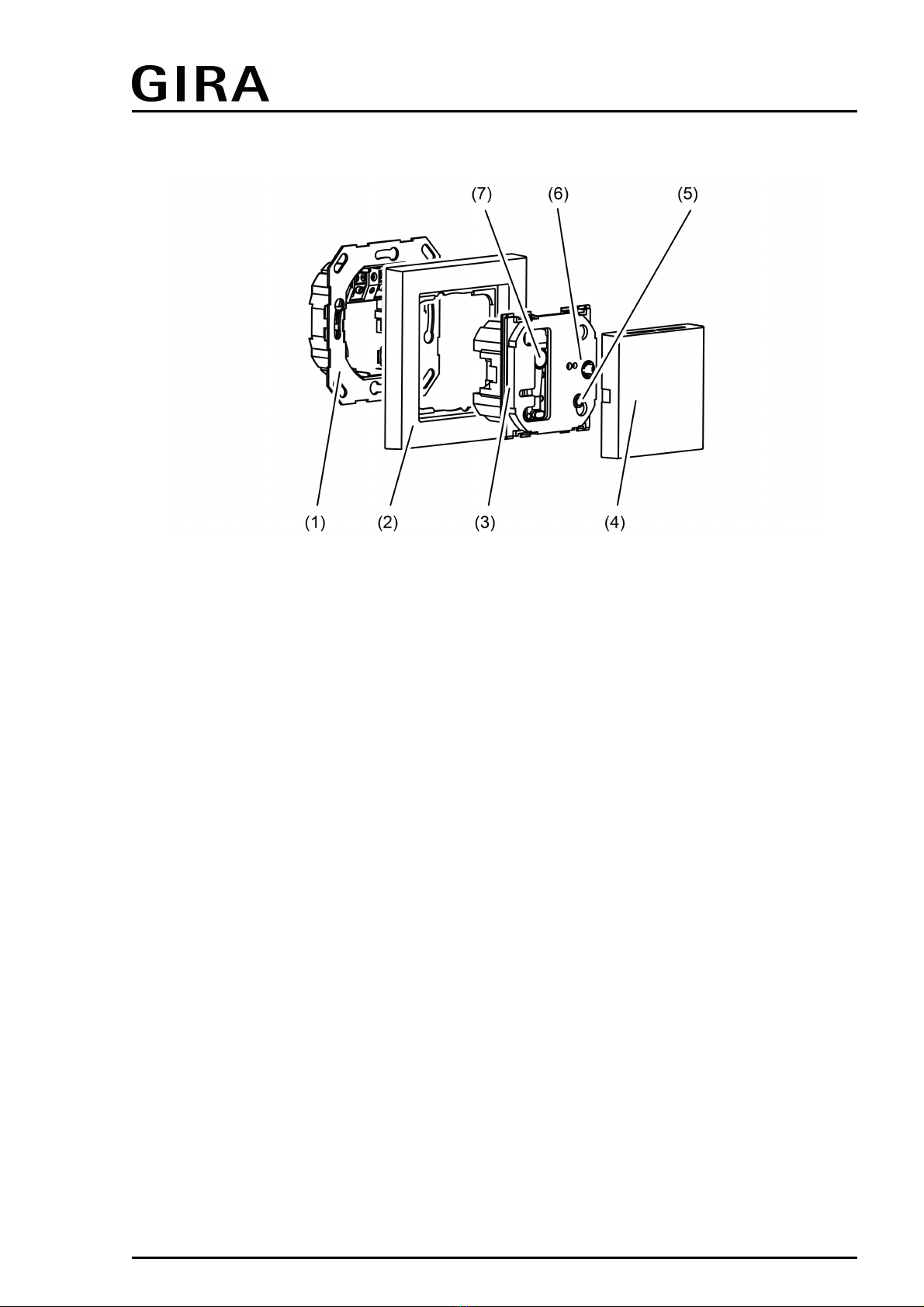

Device components2.2 7........................................................................................................

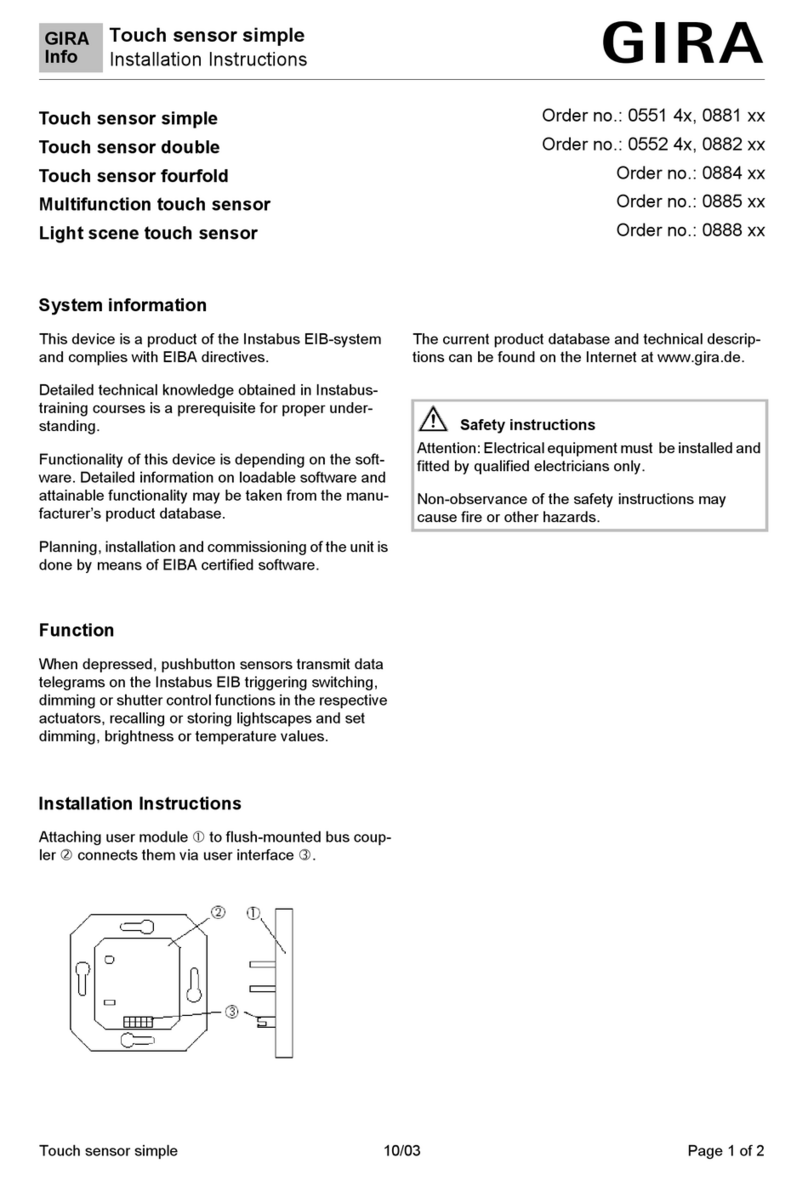

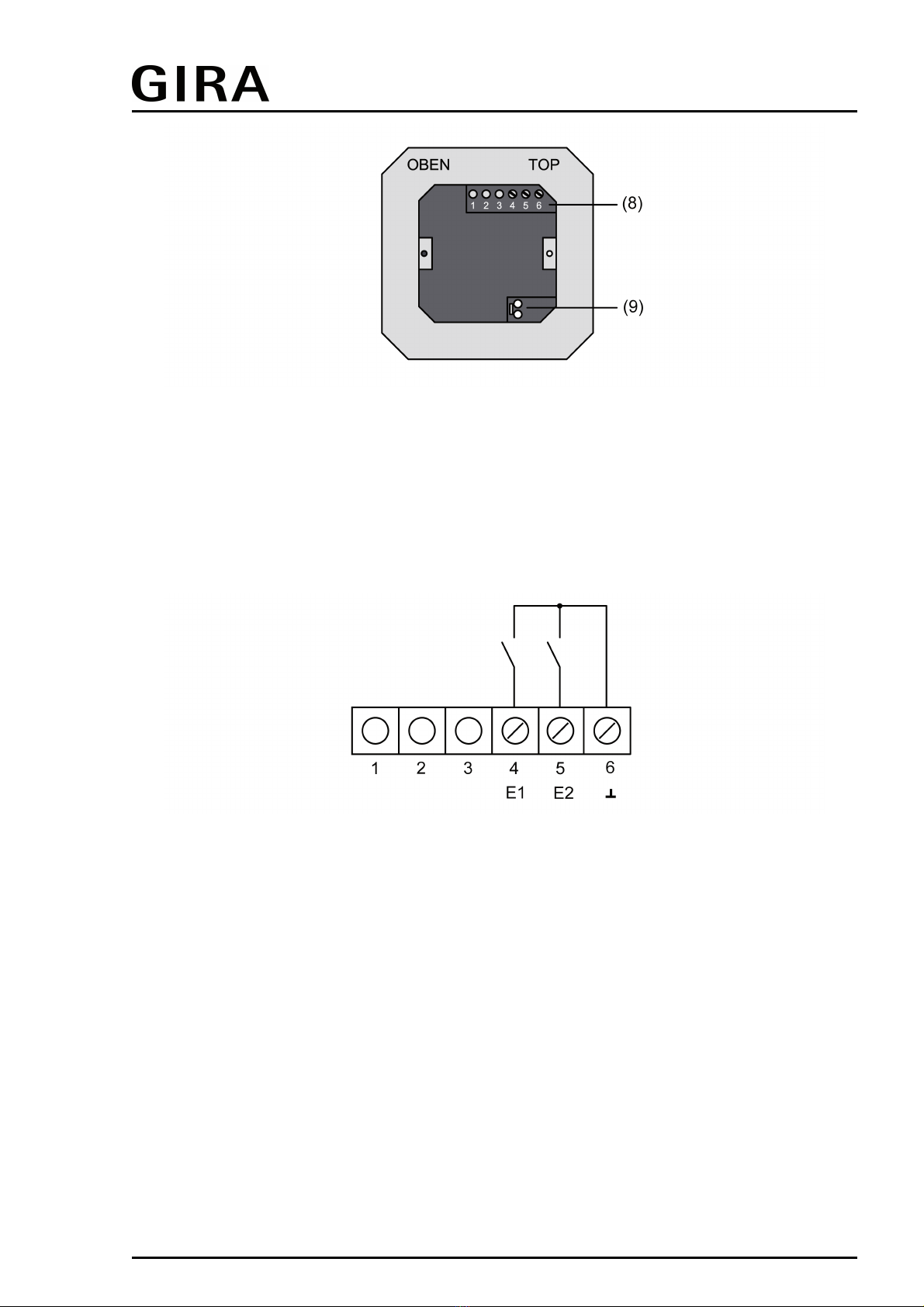

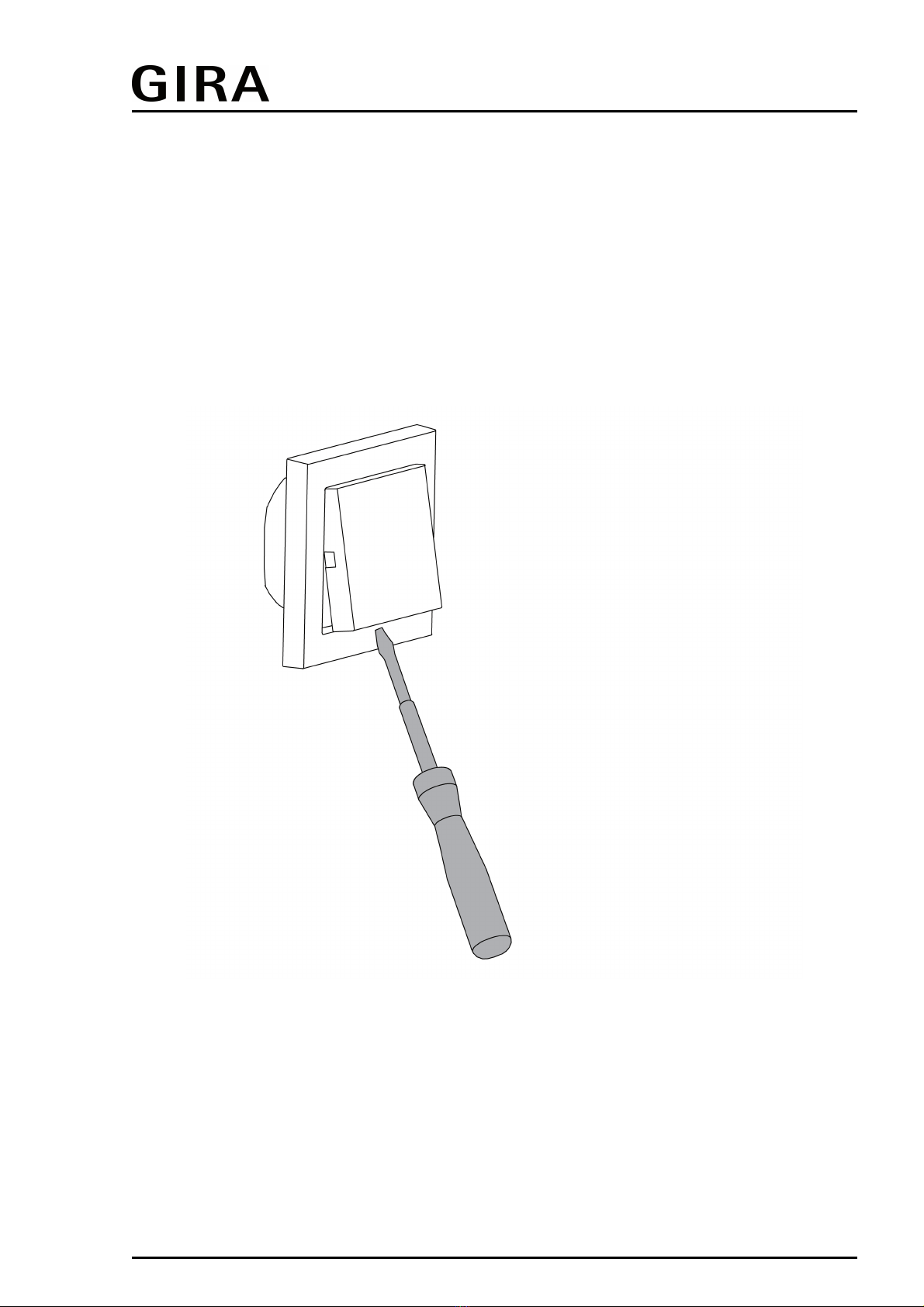

Fitting and electrical connection2.3 8......................................................................................

Commissioning2.4 12.............................................................................................................

Technical data3 13....................................................................................................................

Software description4 14..........................................................................................................

Software specification4.1 14...................................................................................................

Software "KNX CO2 sensor"4.2 15.........................................................................................

Scope of functions4.2.1 15.................................................................................................

Notes on software4.2.2 18..................................................................................................

Object table4.2.3 19...........................................................................................................

Object table push button interface4.2.3.1 19.................................................................

Object table room temperature controller4.2.3.2 22......................................................

Object table sensors4.2.3.3 36......................................................................................

Object table logic gates4.2.3.4 40..................................................................................

Functional description4.2.4 41............................................................................................

Application basics4.2.4.1 41..........................................................................................

Push button interface4.2.4.2 43.....................................................................................

Introduction4.2.4.2.1 43.............................................................................................

Function "no function"4.2.4.2.2 44.............................................................................

"Switching" function4.2.4.2.3 45................................................................................

"Dimming" function4.2.4.2.4 46.................................................................................

"Venetian blind" function4.2.4.2.5 47.........................................................................

Function"Value transmitter 1 byte / 2 byte"4.2.4.2.6 49............................................

Function "Light scene extension with/without memory function"4.2.4.2.7 51............

Response to bus voltage return4.2.4.2.8 52..............................................................

Disabling function of the Inputs4.2.4.2.9 53..............................................................

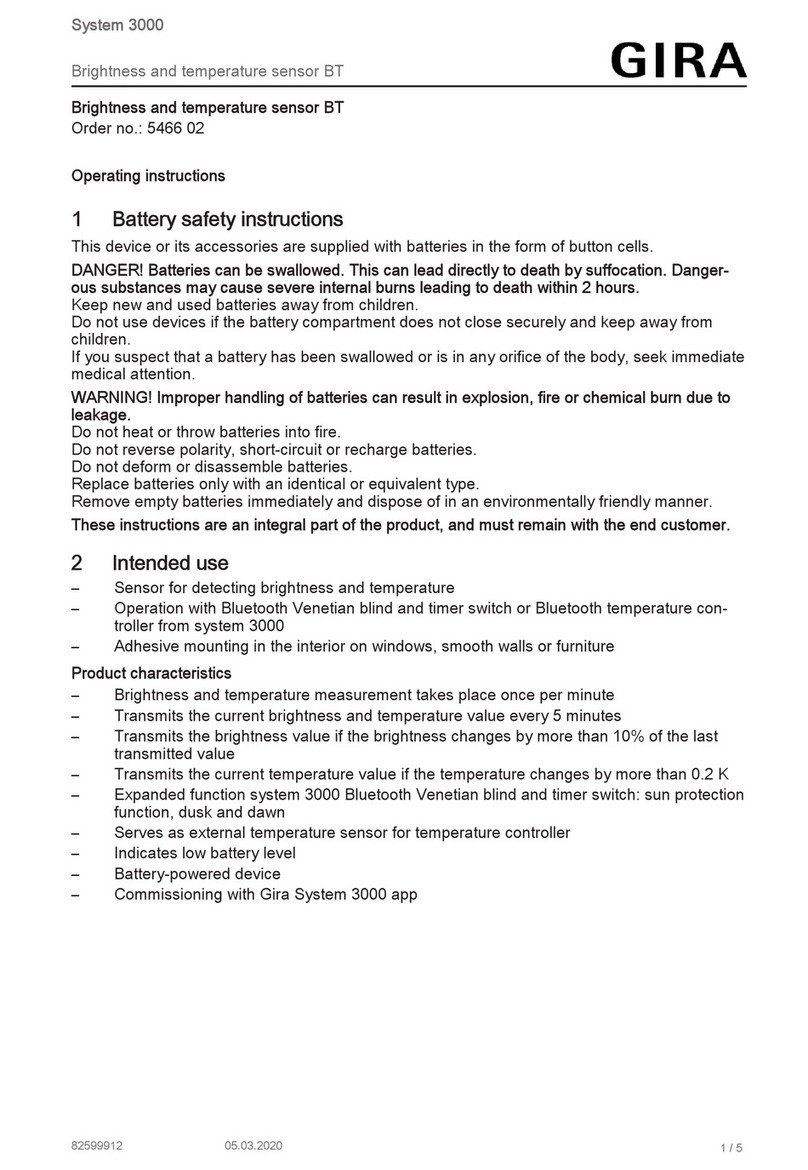

Sensor function4.2.4.3 54..............................................................................................

Temperature sensor4.2.4.3.1 54...............................................................................

Humidity sensor4.2.4.3.2 55......................................................................................

CO2 sensor4.2.4.3.3 56.............................................................................................

Limiting values4.2.4.3.4 58........................................................................................

Room temperature controller4.2.4.4 64.........................................................................

Operating modes and operating mode change-over4.2.4.4.1 64..............................

Control algorithms and calculation of command values4.2.4.4.2 67.........................

Adapting the control algorithms4.2.4.4.3 75..............................................................

Operating mode switchover4.2.4.4.4 78....................................................................

Temperature setpoints4.2.4.4.5 87............................................................................

Room temperature measurement4.2.4.4.6 99...........................................................

Command value and status output4.2.4.4.7 102.......................................................

Disable functions of the room temperature controller4.2.4.4.8 109...........................

KNX

Product documentation

Page 2 of 171