ii

Table of Contents

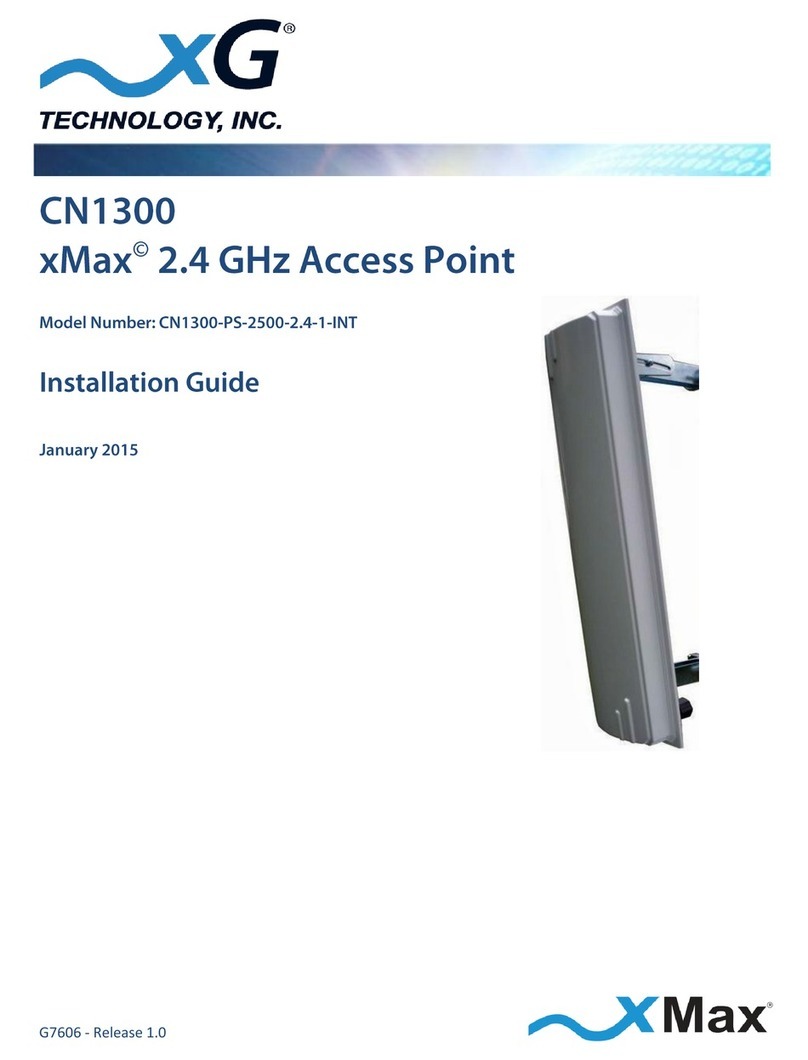

1Product overview··············································································································· 4

Introduction·································································································································4

Hardware configuration················································································································5

Leds········································································································································5

Interfaces································································································································7

2Installation preparations·····································································································10

Unpacking and inspection ·········································································································· 10

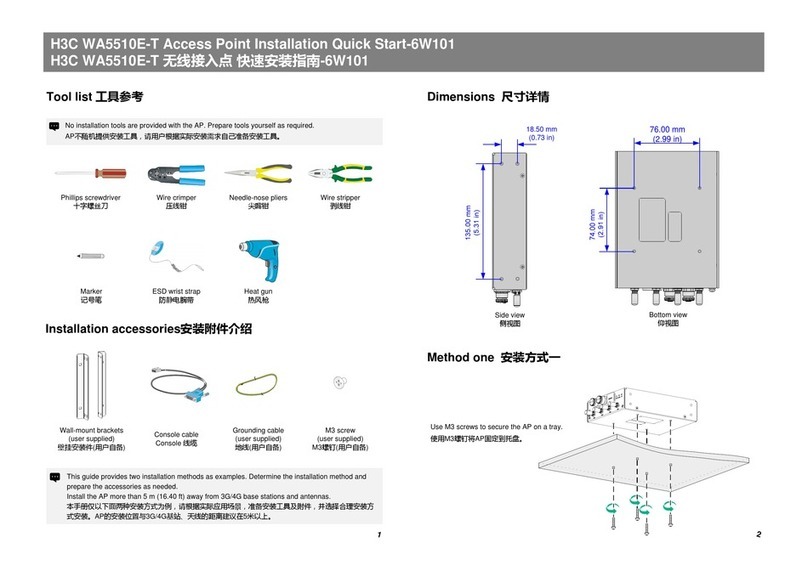

Installation tools·························································································································· 11

Installation site examination ········································································································ 11

Temperature and humidity requirements ················································································· 11

Power supply························································································································· 11

Grounding and lightning protection························································································ 13

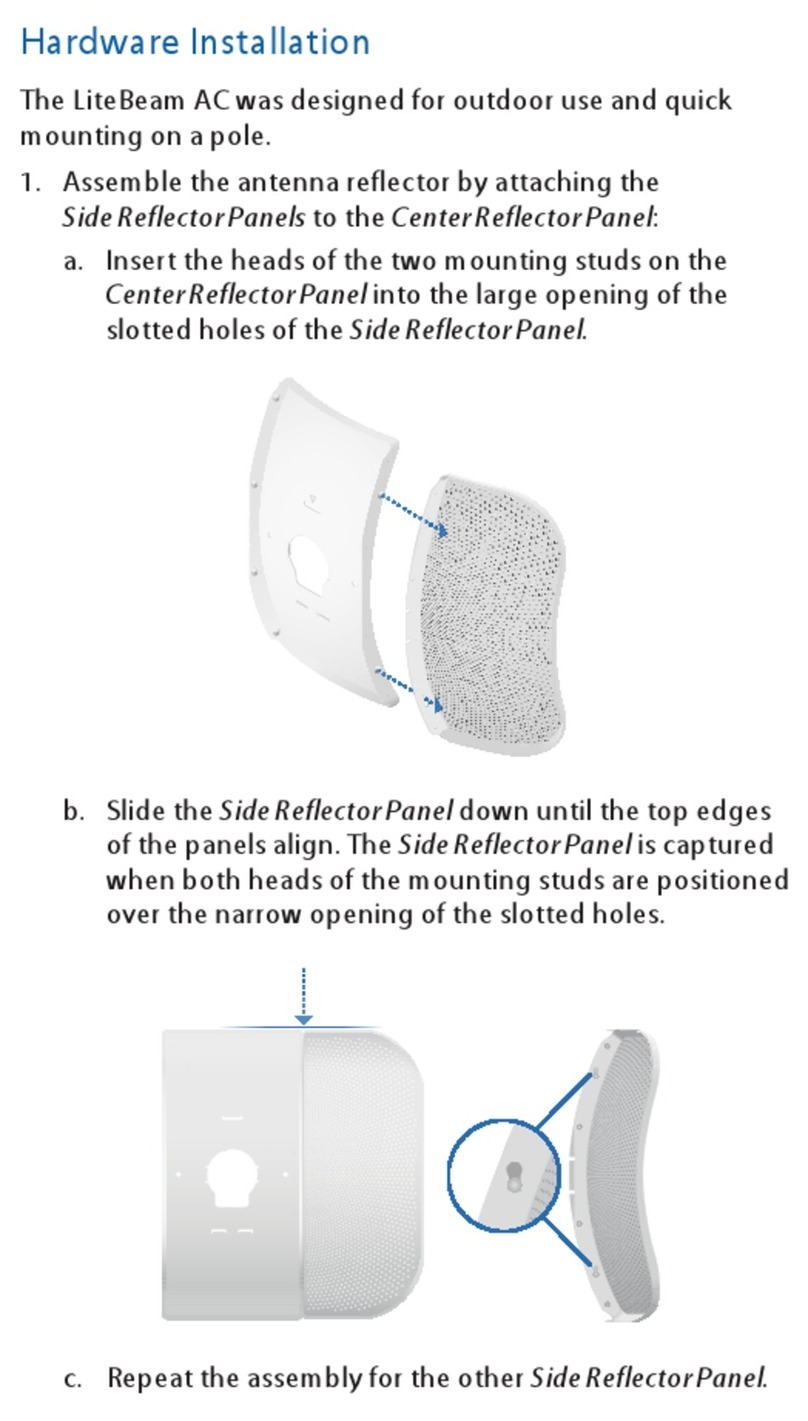

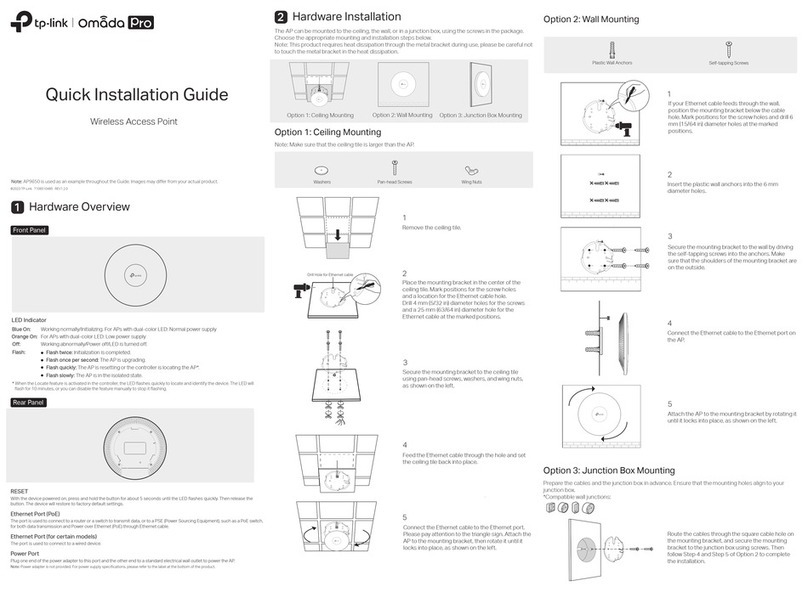

3Installing the AP ················································································································15

Determining the installation position····························································································· 15

Installing the AP on a wall ··········································································································· 15

Installing the wall-mounting bracket on the wall······································································· 15

Installing the AP on the wall-mounting bracket ········································································ 17

Optional: locking the AP onto the wall-mounting bracket························································· 18

Connecting the power supply····································································································· 20

Local power supply················································································································ 20

Power over Ethernet (PoE)······································································································ 20

Connecting the AP to the network ······························································································ 21

4Support and other resources ······························································································22

Related documentation ············································································································· 22

Obtaining documentation ·········································································································· 22

Technical Support ······················································································································ 23

Documentation feedback ····································································································· 23