No.A1560

English

No.A1560

English

Be sure to remove the nut before removing the nipple. Removing the nipple

first could cause the heater leads to twist and cause a short circuit.

Resistance

value of

heating element

Resistance value

of sensor

NOTE :

1

2

3

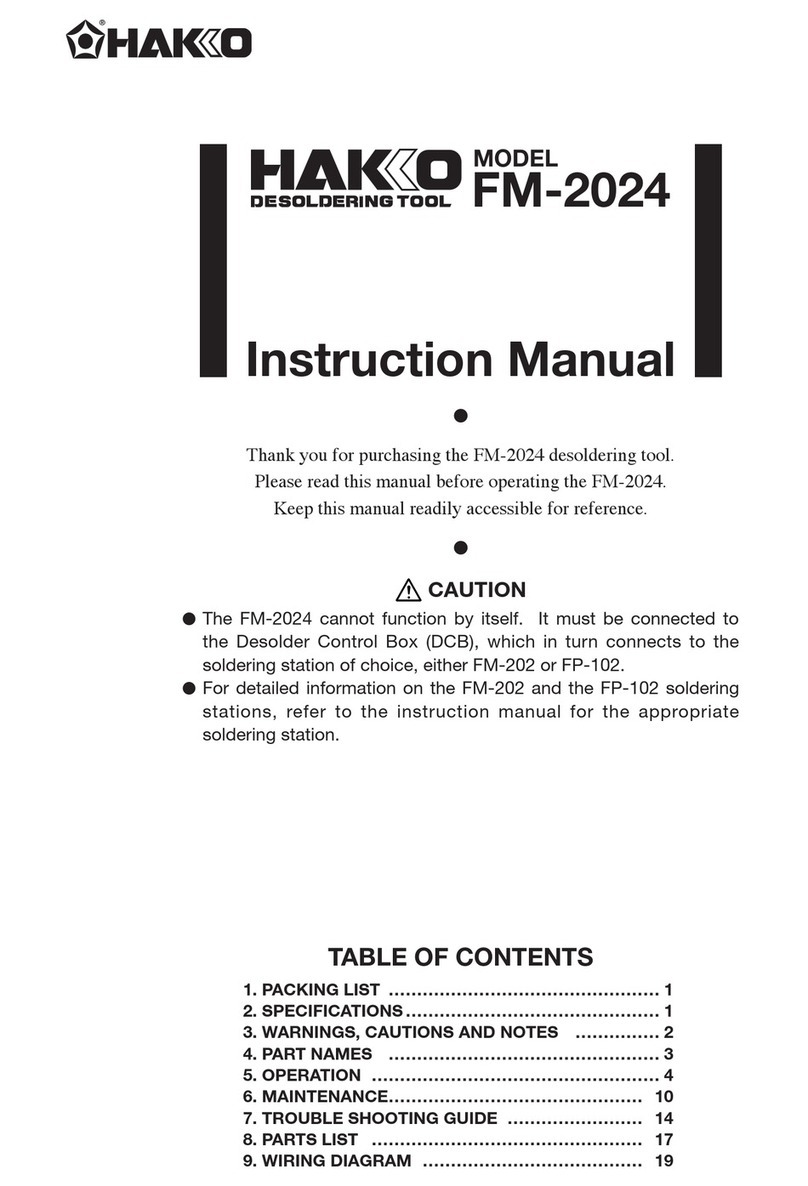

Part Names

Replacing the Heating Element

2

3

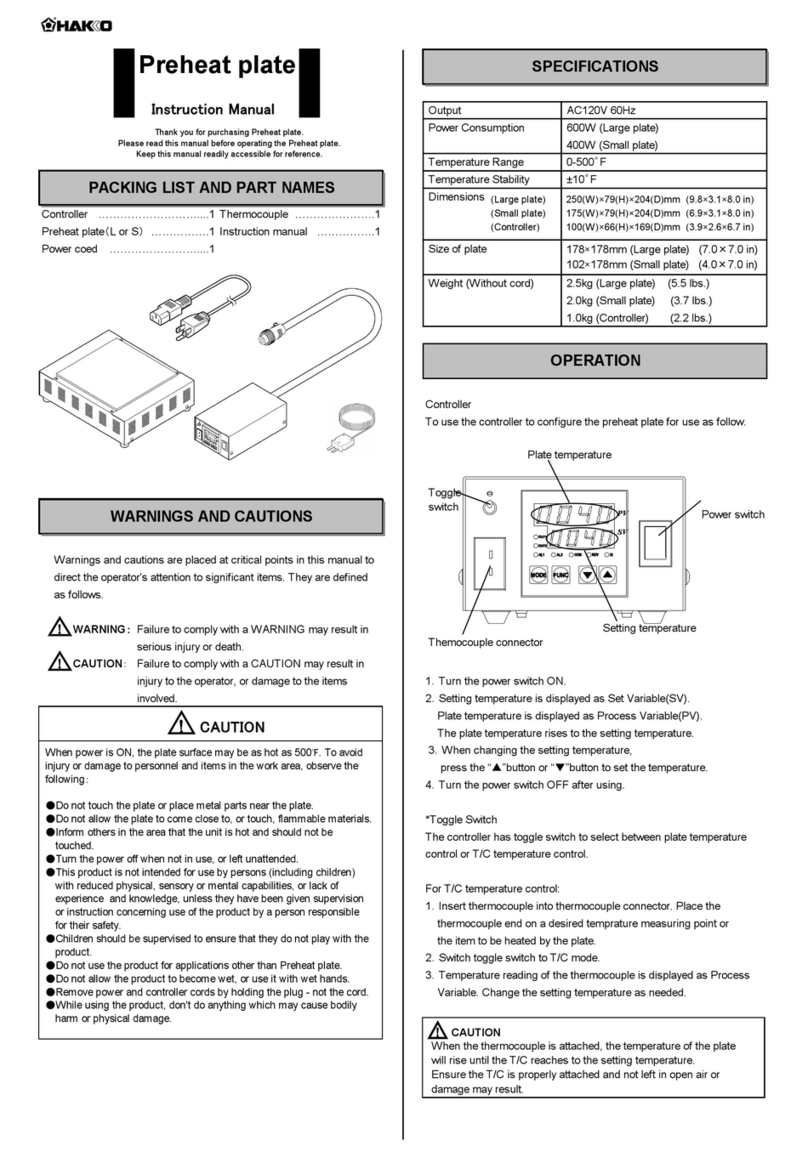

Recalibrate the temperature

To ensure accurate soldering temperatures, always calibrate

the temperature after replacing the heating element.

Connect your iron/gun to the station for calibration.

* Turn the temperature calibrator clockwise to increase the

temperature and counterclockwise to reduce the temperature.

* Remove the CAL pot plug before calibrating HAKKO FX-888.

* We recommend the Thermometer or Soldering tester for

measuring the tip temperature.

Handle

Sleeve

Heating element

Glass tube

Terminal board

Nut

Tip enclosure

Tip

Nipple

Grounding spring

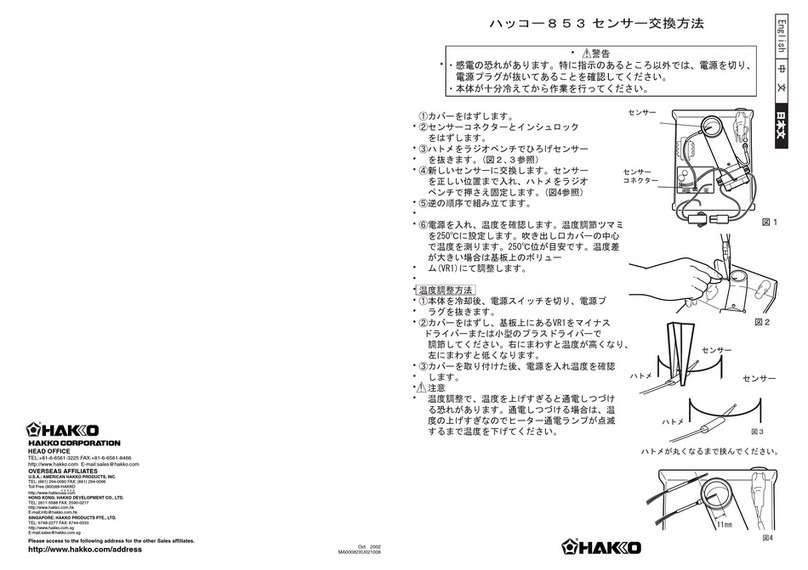

Checking the heating element

Soldering iron

1

Resistance Value

of Heating Element

Resistance Value

of Sensor

Heating Element Leads (Red)

Replacing the heating element

1. Desolder the heating element leads and sensor leads.

Remove the heating element and replace it with a new one.

There is no polarity between leads of the same color.

Adjust the length of the heating element so that length from

end of the terminal board to end of the heating element is 64 mm.

Heating

element

lead

Red

64mm (2.52in)

Straighten the tube. Bend at right angle.

Inspection after replacement

and reassemble

After replacing the heating element,

1. Measure the resistance value between pins 4 & 1, 4 & 2,

pins 5 & 1 and 5 & 2. If it is not ∞, the heating element and

sensor are touching.

2. Measure the resistance value ‘a’, ‘b’, and ‘c’ to confirm that

the leads are not twisted and that the grounding spring is

properly connected.

c

Between pin 3 & Tip

a

Between pins 4 & 5 (Heating Element) 2.5 - 3.5Ω(Normal)

b

Between pins 1 & 2 (Sensor) 43 - 58Ω(Normal)

Under 2Ω

When repairs are needed, please send both the soldering iron

and the station to your sales agent.

*Specifications subject to change without notice.

*This product is protected against electrostatic discharge.

Nut

Tip enclosure

Tip

Nipple

Grounding

spring

Adjusting

screw

Supporting fitting

Glass tube

1. Turn the nut counterclockwise and remove the tip enclosure and the tip.

2. Turn the nipple counterclockwise and remove it from the iron.

3. Pull both the heating element and the cord assembly

out of the handle. (Toward the tip of the iron.)

4. Pull the grounding spring out of the sleeve of the terminal.

1. Remove the adjusting screw and keep the support fitting apart

from the housing.

2. Turn the nut counterclockwise and remove the tip enclosure and tip.

3. Turn the nipple counterclockwise and remove it from the gun.

4. Remove the 4 screws and open the housing.

5. Pull the grounding spring out of the sleeve.

Soldering gun

Measure when the sensor and heating element is at room temperature.

1. Heating element resistance (red) 2.5-3.5 Ω

2. Sensor resistance (blue) 43-58 Ω

If the resistance value is not normal, replace the heating element.

If the resistance value is normal, the cord assembly may be broken.

2. Solder the leads, and then cut extra leads after cooled down.

Pass the leads through the terminal board, push the lead down inside the

terminal board, then solder it. Be sure leads are covered by glass tube.

Cut the wire to leave no more than 1 to 2 mm from the solder joint.

Solder in the joints must be visible from both sides of the terminal board.

1. Set the temperature control knob to 350°C(662°F).

2. Turn the power switch to “ON” and wait until the temperature

stabilizes. Remove the CAL pot plug.

3. When the iron tip temperature stabilizes, measure the tip

temperature using an tip thermometer. As necessary,

fit the included CAL adjustment driver in the hole

in the station indicated by the CAL marking, and

make adjustments so that the tip temperature is 350°C(662°F).

NOTE:

Soldering iron

Soldering gun

A1560_JEC_WIN_200916.indd 2A1560_JEC_WIN_200916.indd 2 2020/09/16 10:34:052020/09/16 10:34:05