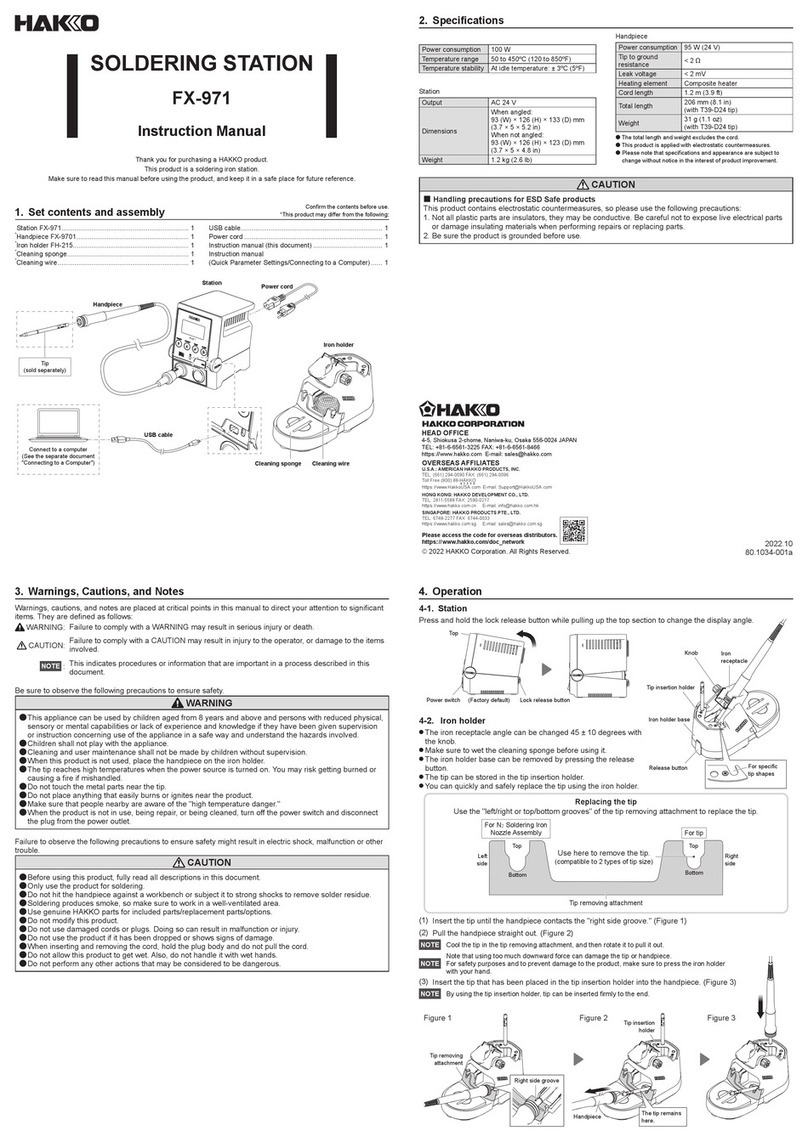

4. OPERATION

7 8

First, plug the power cord into a grounded wall socket,

then open the rear panel of the unit and turn on the Circuit

Breaker.

Check the breaker switch by depressing the test button,

approximately once a month.

Turn on the power switch on the front panel, and set

key switch to MANUAL or AUTO. The unit will begin heating.

Adjust temperature (0-300℃, 32-570℉) with the temperature

control meter. When operating in AUTO, adjust the Digital

solder flow duration meter

(standard setting:250℃・482℉ 4sec.)

When temperature reaches the pre-set one, the temperature

control lamp turns from ▼to ■.

Shortly after, the “READY” lamp will turn on.

The unit is now ready to use.

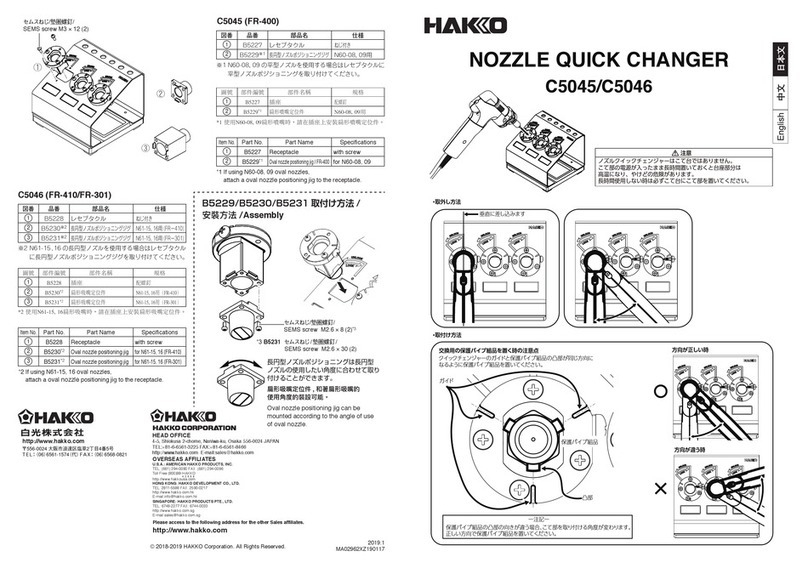

Select the appropriate flow nozzle for your IC and fix it

to the solder flow outlet. Turn the locator light on and

set it to the center of the IC.

NOTE : As a safety feature, the locator light will not

operate until the temperature reaches the pre-set one,

regardless if the switch is turned on.

CAUTION

Mode - AUTO

Before selecting AUTO mode, turn the key switch to MANUAL.

Depress the foot switch and adjust the solder flow as desired

using the solder flow dial. Then turn the key switch to

AUTO mode.

Set the solder flow duration according to your needs.

Put a P.W.B. on the table, then set the locator light

to the center of the IC.

Depress the foot switch. Watch carefully to see when

the solder has become molten. At that time remove the IC.

Should it not remove easily, depress the foot switch once

more. The solder will flow only for the duration set on the

flow timer.

Connect the HAKKO 486(AIR UNIT) to the unit with 3P

metal connector. Turn the AIR UNIT switch to ON in order

to prepare for cleaning. Next, switch the MODE key on

the unit to AUTO, then, using a P.W.B. to test, set the solder

flow duration according to your needs.

Adjust Slow down control dial, Air pressure dial, Air blow

duration dial and Air blow timing dial.

Put a P.W.B. on the table and set the locator light where

the IC had been. Then place the hood of the air cleaning

hose over the section to be cleaned and lightly depress

the foot switch. Be especially careful not to press the P.W.B.

too much with your hands, as the solder will overflow through

the holes. After the solder has run out, compressed air from

the air hood cleans IC holes for the pre-set time period.

Other Uses

If an IC is defective or does not operate properly, it may

be replaced with a new IC. Remove defective IC, spray

flux on backside of board, and attach new IC using the

same procedure as above.

Excessive solder on the leads of the IC or other components

can be removed easily. Depress the foot switch and briefly

dip the leads into the solder bath.

It is also possible to attach various sized connects by

special ordering separate nozzle attachments from us.

NOTE :

After finishing the work, turn off the power switch.

Mode - MANUAL

Compressed air cleaning - after removal of IC

For safety reasons, be sure to ground the unit

by connecting the ground wire to a grounded terminal.

NOTE :

Without setting the key switch

to MANUAL or AUTO, the heater

will not begin heating.

Turn the key switch to MANUAL mode.

Depress the foot switch and adjust the solder flow as

desired using the solder flow dial.

Put a P.W.B. on the table, and set locator light to

the center of IC.

Depress the foot switch. Watch carefully to see when

the solder has become molten. At that time remove the IC.

NOTE :

As solder continues to flow while the foot switch

is depressed, remove your foot from switch just before

removing IC from the table.

An inter-locking device prevents the motor, the foot switch,

and the locator lamp from operating until the “READY”

lamp is lit.