7

Subject to change without notice

Field of application

The instrument is specified for operation in industry, light industry,

commercial and residential environments.

The instrument has been designed for indoor use. The permissible

ambient temperature range during operation is +10°C (+50°F) ...

+40°C (+104°F). It may occasionally be subjected to temperatures

between +10°C (+50°F) and -10°C (+14°F) without degrading its

safety. The permissible ambient temperature range for storage or

transportation is -40°C (-40°F) ... +70°C (+158°F). The maximum

operating altitude is up to 2200m (non-operating 15000m). The

maximum relative humidity is up to 80%.

If condensed water exists in the instrument it should be

acclimatized before switching on. In some cases (e.g. extremely

cold oscilloscope) two hours should be allowed before the

instrument is put into operation. The instrument should be kept

in a clean and dry room and must not be operated in explosive,

corrosive, dusty, or moist environments. The oscilloscope can be

operated in any position, but the convection cooling must not be

impaired. The ventilation holes may not be covered. For continuous

operation the instrument should be used in the horizontal position,

preferably tilted upwards, resting on the tilt handle.

The specifications stating tolerances are only valid if the instrument

has warmed up for 30minutes at an ambient temperature between

+15°C (+59°F) and +30°C (+86°F). Values without tolerances are

typical for an average instrument.

EMC

This instrument conforms to the European standards regarding

the electromagnetic compatibility. The applied standards are:

Generic immunity standard EN50082-2:1995 (for industrial

environment) Generic emission standard EN50081-1:1992 ( for

residential, commercial and light industry environment).

This means that the instrument has been tested to the highest

standards. Please note that under the influence of strong

electromagnetic fields, such signals may be superimposed

on the measured signals.

Under certain conditions this is

unavoidable due to the instrument’s high input sensitivity, high

input impedance and bandwidth. Shielded measuring cables,

shielding and earthing of the device under test may reduce or

eliminate those effects.

Warranty

HAMEG warrants to its Customers that the products it

manufactures and sells will be free from defects in materials

and workmanship for a period of 2 years. This warranty shall

not apply to any defect, failure or damage caused by improper

use or inadequate maintenance and care. HAMEG shall not be

obliged to provide service under this warranty to repair damage

resulting from attempts by personnel other than HAMEG

representatives to install, repair, service or modify these products.

In order to obtain service under this warranty, Customers must

contact and notify the distributor who has sold the product. Each

instrument is subjected to a quality test with 10 hour burn-in

before leaving the production. Practically all early failures are

detected by this method. In the case of shipments by post, rail

or carrier the original packing must be used. Transport damages

and damage due to gross negligence are not covered by the

guarantee.

In the case of a complaint, a label should be attached to the

housing of the instrument which describes briefly the faults

observed. If at the same time the name and telephone number

(dialing code and telephone or direct number or department

designation) is stated for possible queries, this helps towards

speeding up the processing of guarantee claims.

Maintenance

Various important properties of the oscilloscope should be

carefully checked at certain intervals. Only in this way is it largely

certain that all signals are displayed with the accuracy on which

the technical data are based. Purchase of the HAMEG scope

tester HZ 60, which despite its low price is highly suitable for

tasks of this type, is very much recommended. The exterior of

the oscilloscope should be cleaned regularly with a dusting brush.

Dirt which is difficult to remove on the casing and handle, the

plastic and aluminum parts, can be removed with a moistened

cloth (99% water +1% mild detergent). Spirit or washing benzene

(petroleum ether) can be used to remove greasy dirt. The screen

may be cleaned with water or washing benzene (but not with

spirit (alcohol) or solvents), it must then be wiped with a dry

clean lint-free cloth. Under no circumstances may the cleaning

fluid get into the instrument. The use of other cleaning agents

can attack the plastic and paint surfaces.

Protective Switch Off

This instrument is equipped with a switch mode power supply. It

has both over voltage and overload protection, which will cause

the switch mode supply to limit power consumption to a

minimum. In this case a ticking noise may be heard.

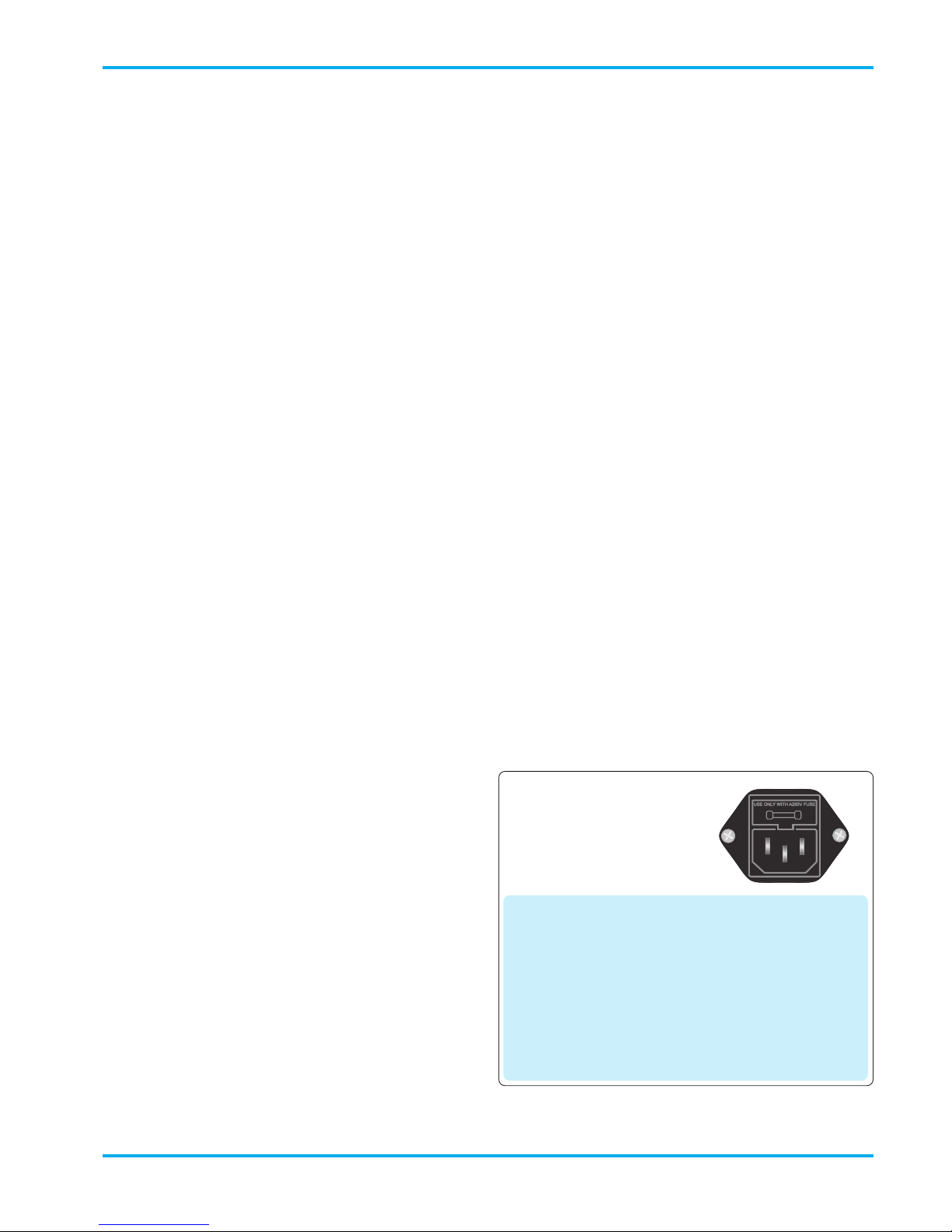

Power supply

The instrument operates on mains/line voltages between 100VAC

and 240VAC. No means of switching to different input voltages

has therefore been provided.

The power input fuse is externally accessible. The fuse holder

and the 3 pole power connector is an integrated unit. The power

input fuse can be exchanged after the rubber connector is

removed. The fuse holder can be released by lever action with

the aid of a screwdriver. The starting point is a slot located on

contact pin side. The fuse can then be pushed out of the mounting

and replaced.

The fuse holder must be pushed in against the spring pressure

and locked. Use of patched fuses or short circuiting of the fuse

holder is not permissible; HAMEG assumes no liability whats-

oever for any damage caused as a result, and all warranty claims

become null and void.

Fuse type:

Size 5x20mm; 0.8A, 250V AC fuse;

must meet IEC specification 127,

Sheet III (or DIN 41 662

or DIN 41 571, sheet 3).

Time characteristic: time lag.

Attention!

There is a fuse located inside the instrument within

the switch mode power supply:

Size 5x20mm; 0.8A, 250V AC fuse;

must meet IEC specification 127,

Sheet III (or DIN 41 662

or DIN 41 571, sheet 3).

Time characteristic: fast (F).

The operator must not replace this fuse!

Important hints