Subject to change without notice

8

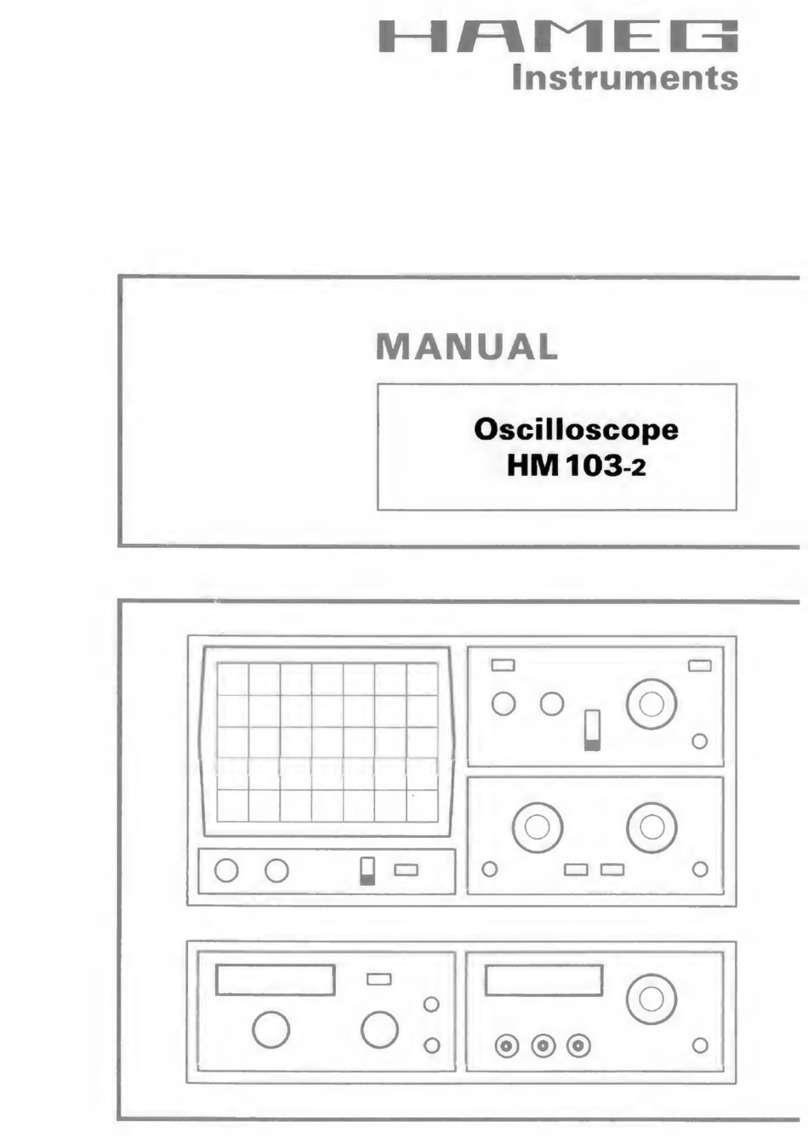

Voltage values of a sine curve

Vrms = effective value; Vp= simple peak or crest value;

Vpp = peak to peak value; Vmom = momentary value.

The minimum signal voltage which must be applied to the Y input

for a trace of 1div height is 1mVpp (± 5%) with this deflection

coefficient displayed on the screen (readout) and the vernier

switched off (VAR-LED dark). However, smaller signals than this

may also be displayed. The deflection coefficients are indicated

in mV/div or V/div (peak to peak value).

The magnitude of the applied voltage is ascertained by multiplying

the selected deflection coefficient by the vertical display height

in div. If an attenuator probe x10 is used, a further multiplication

by a factor of 10 is required to ascertain the correct voltage value.

This factor can be entered into the oscilloscope’s memory for

automatic calculation.

For exact amplitude measurements, the variable control (VAR)

must be set to its calibrated detent CAL position.

With the variable control activated the deflection sensitivity can

be reduced up to a ratio of 2.5 to 1 (

please note ”controls and

readout”

). Therefore any intermediate value is possible within

the 1-2-5 sequence of the attenuator(s).

With direct connection to the Y input, signals up to 400 Vpp

may be displayed (attenuator set to 20 V/div, variable

control to 2.5:1).

With the designations

H = display height in div,

U = signal voltage in Vpp at the Y input,

D = deflection coefficient in V/div at attenuator switch,

the required value can be calculated from the two given quantities:

However, these three values are not freely selectable. They have

to be within the following limits (trigger threshold, accuracy of

reading):

H between 0.5 and 8div, if possible 3.2 to 8div,

U between 0.5 mVpp and 160 Vpp,

D between 1 mV/div and 20 V/div in 1-2-5 sequence.

Examples:

Set deflection coefficient D = 50 mV/div 0.05 V/div,

observed display height H = 4.6 div,

required voltage U = 0.05x4.6 = 0.23 Vpp.

Type of signal voltage

The oscilloscope HM504-2 allows examination of DC voltages

and most repetitive signals in the frequency range up to at least

50 MHz (–3 dB).

The Y amplifiers have been designed for minimum overshoot and

therefore permit a true signal display.

The display of sinusoidal signals within the bandwidth limits

causes no problems, but an increasing error in measurement due

to gain reduction must be taken into account when measuring

high frequency signals. This error becomes noticeable at approx.

14 MHz. At approx. 30 MHz the reduction is approx. 10% and the

real voltage value is 11% higher. The gain reduction error can not

be defined exactly as the –3 dB bandwidth of the Y amplifiers

differs between 50 MHz and 55 MHz.

When examining square or pulse type waveforms, attention

must be paid to the harmonic content of such signals. The

repetition frequency (fundamental frequency) of the signal must

therefore be significantly smaller than the upper limit frequency

of the Y amplifiers.

Displaying composite signals can be difficult, especially if they

contain no repetitive higher amplitude content that can be used

for triggering. This is the case with bursts, for instance. To obtain

a well triggered display in this case, the assistance of the variable

holdoff function or the delayed time base may be required.

Television video signals are relatively easy to trigger using the

built in TV Sync Separator (TV).

For optional operation as a DC or AC voltage amplifier, each Y

amplifier input is provided with a DC/AC switch. DC coupling should

only be used with a series connected attenuator probe or at very

low frequencies, or if the measurement of the DC voltage content

of the signal is absolutely necessary.

When displaying very low frequency pulses, the flat tops may be

sloping with AC coupling of the Y amplifier (AC limit frequency

approx. 1.6 Hz for 3dB). In this case, DC operation is preferred,

provided the signal voltage is not superimposed on too high a DC

level. Otherwise a capacitor of adequate capacitance must be

connected to the input of the Y amplifier with DC coupling. This

capacitor must have a sufficiently high breakdown voltage rating.

DC coupling is also recommended for the display of logic and

pulsesignals,especiallyifthepulsedutyfactorchangesconstantly.

Otherwise the display will move upwards or downwards at each

change. Pure direct voltages can only be measured with DC

coupling.

Amplitude Measurements

In general electrical engineering, alternating voltage data normally

refers to effective values (rms = root mean square value).

However, for signal magnitudes and voltage designations in

oscilloscope measurements, the peak to peak voltage (Vpp) value

is applied. The latter corresponds to the real potential difference

between the most positive and most negative points of a signal

waveform.

If a sinusoidal waveform, displayed on the oscilloscope screen,

is to be converted into an effective (rms) value, the resulting peak

to peak value must be divided by 2 x √2 = 2.83. Conversely, it

should be observed that sinusoidal voltages indicated in Vrms

(Veff) have 2.83 times the potential difference in Vpp. The

relationship between the different voltage magnitudes can be

seen from the following figure.

Type of signal voltage