-8-

RECOGNIZE SAFETY INFORMATION

This is the safety-alert symbol. When you see this

symbol on your machine or in this manual, be alert to the

potential for personal injury.

Follow recommended precautions and safe operating

practices.

UNDERSTAND SIGNAL WORDS

A single word; DANGER, WARNING, or CAUTION is used

with the safety-alert symbol. DANGER identifies the most

serious hazards.

Safety signs with signal word DANGER or WARNING are

typically near specific hazards.

General precautions are listed on CAUTION safety signs.

FOLLOW SAFETY INSTRUCTIONS

Carefully read all safety messages in this manual, and all safety signs on your machine. Follow all

recommended precautions and safe operating procedures.

SAFETYINFORMATION

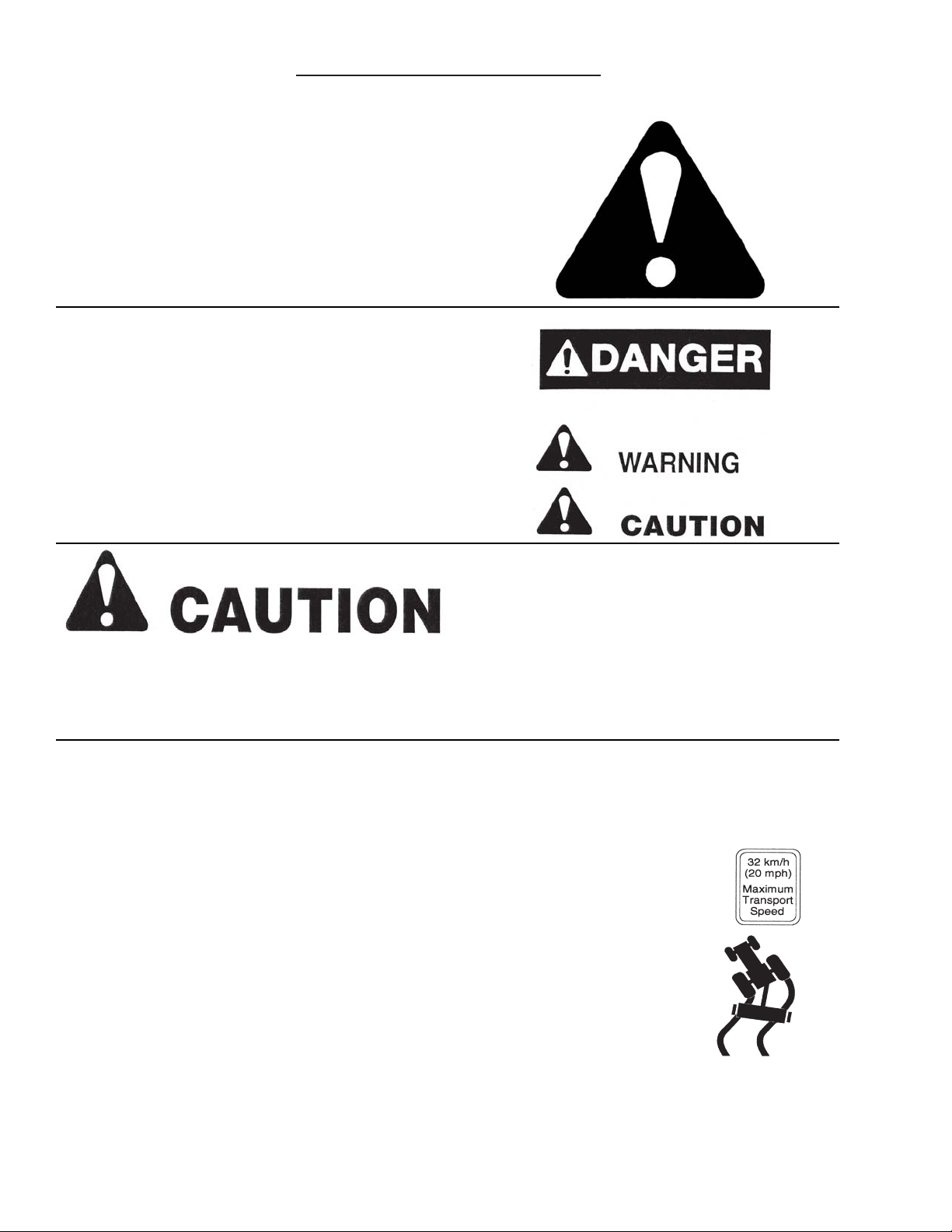

OBSERVE MAXIMUM TRANSPORT SPEED

The maximum transport speed for this implement is 32 km/h (20 m.p.h.).

Some tractors are capable of operating at speeds that exceed the maximum

transport speed of this implement. Regardless of the maximum speed capability

of the tractor being used to tow this implement, do not exceed the implement’s

maximum transport speed.

Exceeding the implements maximum transport speed can result in:

* Loss of control of the tractor/implement combination

* Reduced or no ability to stop during braking

* Implement tire failure

* Damage to the implement structure or its components

Use additional caution and reduce speed when towing under adverse surface

conditions, when turning, and when on inclines.

Do not attempt transport if the fully loaded implement weighs more than 1.5 times

the weight of the tractor.

Keep signs in good condition. Immediately replace any missing or damaged signs.