- 4 -

16. Before traveling on public roads, put the machine into its transport position as instructed in this operators

manual.

17. Never leave the tractor seat while the machine is operating.

18. Drive speed must be adapted to ground conditions as well as to roads and paths.

Always avoid abrupt changes of direction.

19. Precision steering, tractor adherence, road holding and efficient braking are influenced by the type of

implement, weight, ballast of front axle, ground or road conditions. It is therefore of utmost importance to

be cautious in every given situation.

20. Be particularly cautious when turning corners, paying attention to machine overhang, length, height and

weight.

21. Before operating the machine, ensure that all safety guards are firmly in place and in good condition. If worn

or damaged, replace immediately.

22. Before operating the machine, check the tightness of all nuts and bolts, particularly on fixing elements

(blades, tines, knives, spades ...)

23. Keep clear of the machine operating area.

24. WARNING ! Danger of crushing and shearing can exist when components are operated by hydraulic or

pneumatic controls.

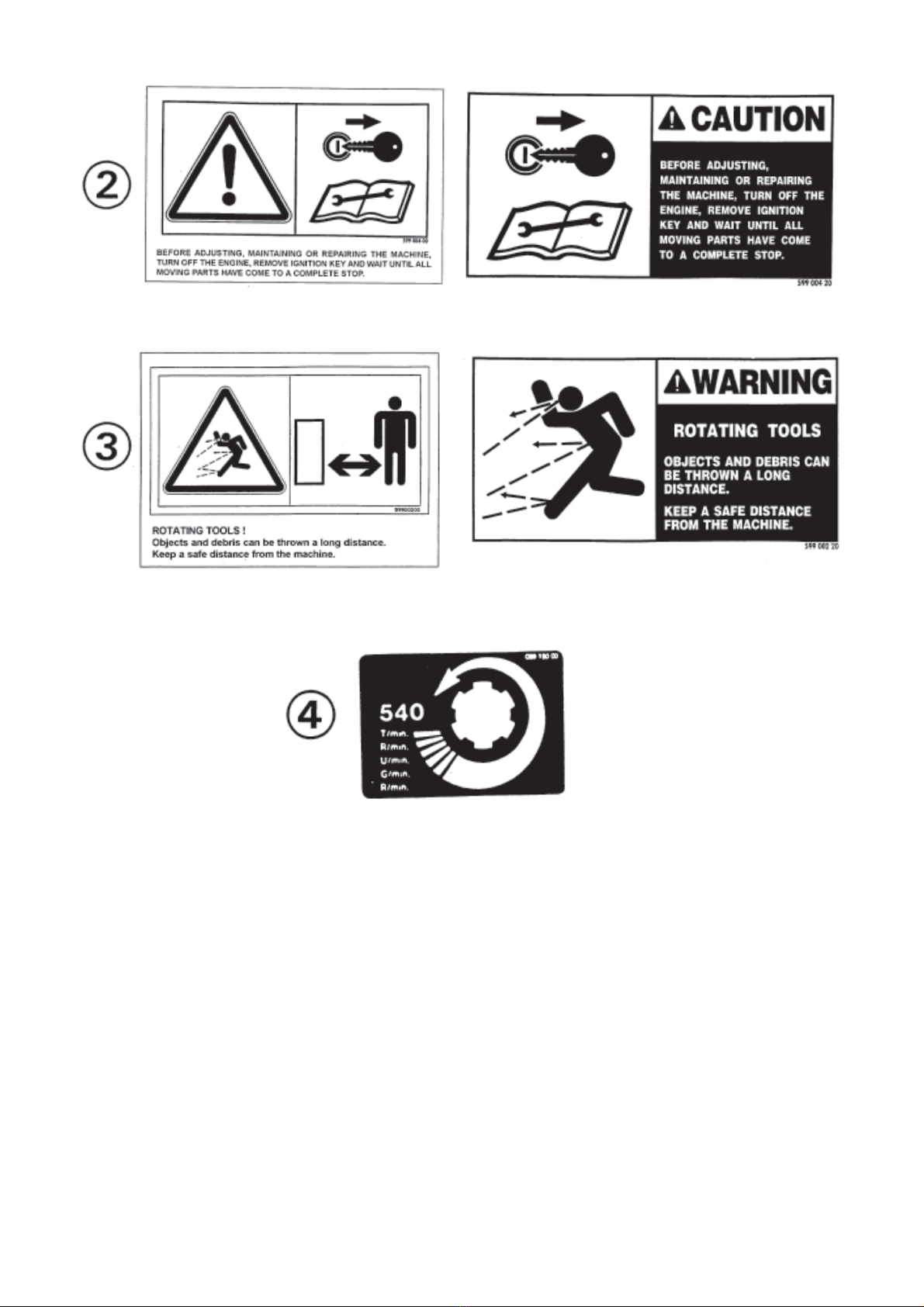

2 . Before leaving the tractor or before adjusting, maintaining or repairing the machine, turn off the engine,

remove the ignition key and wait until all moving parts have come to a complete stop.

26. Do not stand between the tractor and the machine unless the hand brake is tight and/or stops have been

placed under the wheels.

27. Before any adjustments, maintenance or repairs are carried out, ensure that the machine cannot be started

up accidentally.

ATTACHMENT

1. When attaching or removing the machine from the tractor, position hydraulic lift control lever in such a way that

it cannot be set off accidentally.

2. When attaching the machine to the tractor hydraulic linkage, ensure that diameter of the link pins correspond

to the diameter of the ball joints.

3. WARNING ! Danger of crushing and shearing can exist in the lifting zone of the tractor hydraulic linkage !

4. Do not stand between the tractor and the machine when operating the outer control lever of the lift mechanism.

. In transport, the machine lift mechanism should be stabilized by tractor tie rods to avoid floatation and side

shifting.

6. When transporting the machine ensure that it can not be lowered accidentally.