9

RTN/M2

A1867-2.0 en/de/fr/es HBM

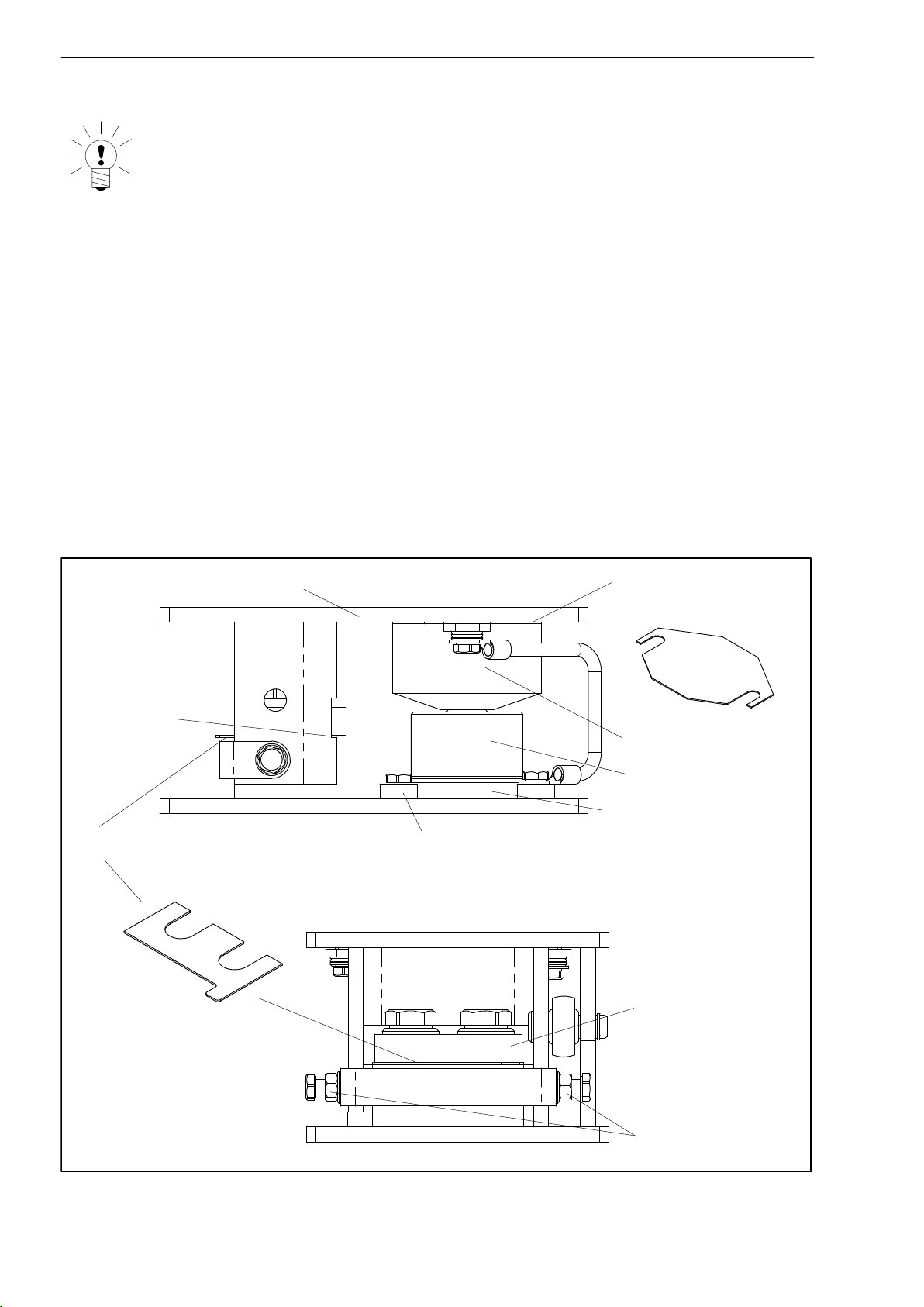

2 Mounting preparation

Caution:

The weighing modules are delivered completely assembled , however,

without a load cell. Instead of the load cell, a dummy has been assembled

into the weighing module, which is capable of taking up the specified loads.

Before the weighing module is mounted underneath the tank, vessel or silo,

check whether dummy replacement through the load cell will still be possible

even if the tank is placed on the weighing module. In order to effect the re-

placement, a suitable lifting device is necessary that is capable of lifting the

tank by at least 10 mm. Pipe connections mounted on the tank or the feed‐in

or discharge systems have to be vertically movable or separable.

NOTE

If this is not the case, the dummy must be replaced by an appropriate

RTN load cell already before the weighing module is mounted.

General mounting preparations

Ensure that the assembly/siting areas provided are clean, level and hori-

zontally aligned. Any askew positions can be compensated for, depending

on the assembly situation, for example by appropriate wedges and com-

pensation plates (weld in position) or by grinding down the assembly area.

However, module plates must not be ground down under any circum-

stances.

The foundations / basic construction and the connection of the

superstructure must be sufficiently rigid in order to avoid deformations (e.g.

deflections) under load.

In order to provide for fitting and assembly free from any constraining

forces, the mounting bores on the basic construction and the tank connec-

tion must be sufficiently aligned.

An even loading on the bearing points is to be sought. To this end, in par-

ticular for statically indefinite bearings, ensure that the height level setting

at the bearing points is correct (provide spacer plates, 5 x 1 mm included

in scope of delivery).

Undo transport protection device and stops, fit height adjustment plates

(dependent on maximum capacity, see Dimensions).