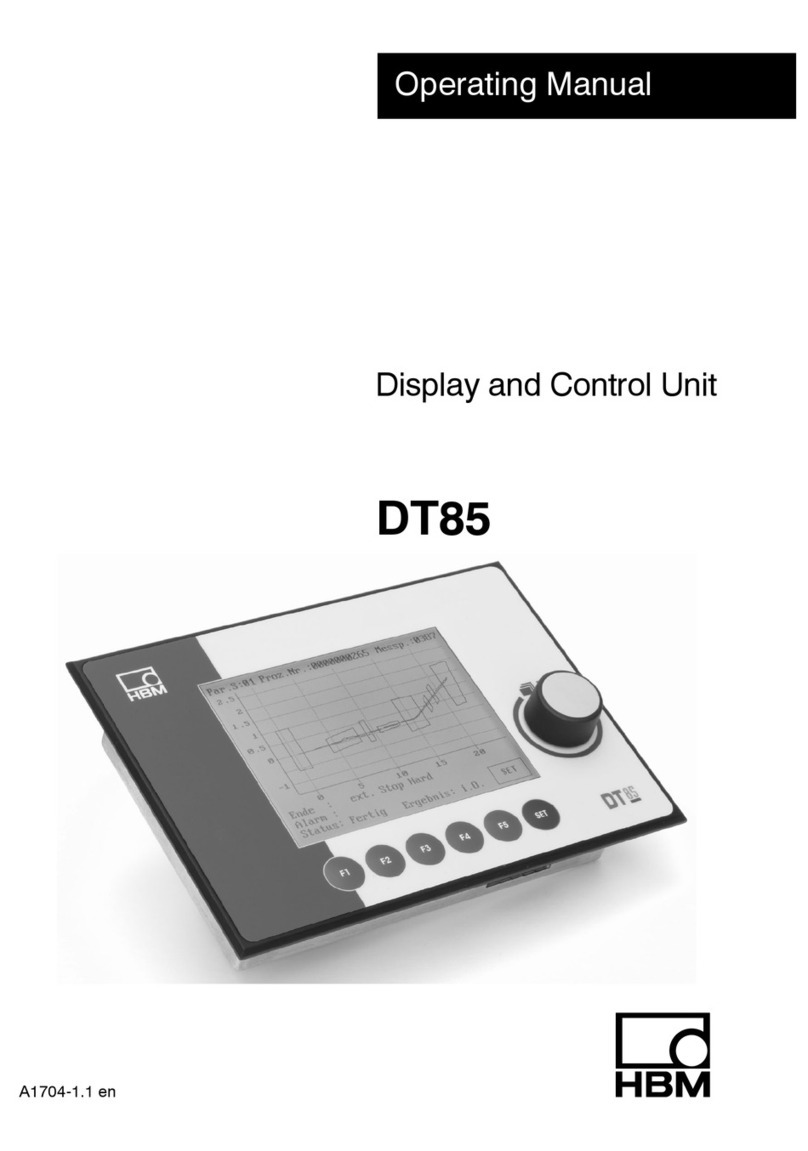

6DT85

HBM A1704−3.3 en/de

Working safely

Error messages must only be acknowledged once the cause of the error has

been eliminated and the danger no longer exists.

The device complies with the safety requirements of DIN EN 61010 Part 1

(VDE 0411 Part 1).

To ensure adequate immunity from interference, the bus lines must be

shielded cables.

The power supply connection cables always need to be shielded.

When connecting the cables (attaching and detaching terminals), action must

be taken to prevent electrostatic discharge which could damage the

electronics.

The DT85 must be operated on a safety extra−low voltage (supply voltage

18...30 V DC), which usually supplies power to one or more consumers within

a control cabinet.

Should the device be operated on a dc voltage network1), additional

precautions must be taken to discharge excess voltages.

The supply connection, as well as the signal and sense leads, must be

installed in such a way that electromagnetic interference does not adversely

affect device functionality (HBM recommendation: ”Greenline shielding

design”, downloadable from the Internet at http://www.hbm.com/Greenline).

Automation equipment and devices must be covered over in such a way that

adequate protection or locking against unintentional actuation is provided

(such as access checks, password protection, etc.).

When devices are working in a network, these networks must be designed in

such a way that malfunctions in individual nodes can be detected and shut

down.

Safety precautions must be taken both in terms of hardware and software, so

that a line break or other interruptions to signal transmission, such as via the

bus interfaces, do not cause undefined states or loss of data in the

automation device.

Conversions and modifications

The DT85 display must not be modified from the design or safety engineering

point of view except with our express agreement. Any modification shall

exclude all liability on our part for any damage resulting there from. In

particular, any repair or soldering work on motherboards is prohibited. When

exchanging complete modules, use only original parts from HBM.

1) Distribution system for electrical energy with greater spatial expansion (e.g. over a number of control

cabinets) that may even supply consumers with large nominal currents.