6PME-MP70DP

HBM A0658−7.2 en

Appropriate use

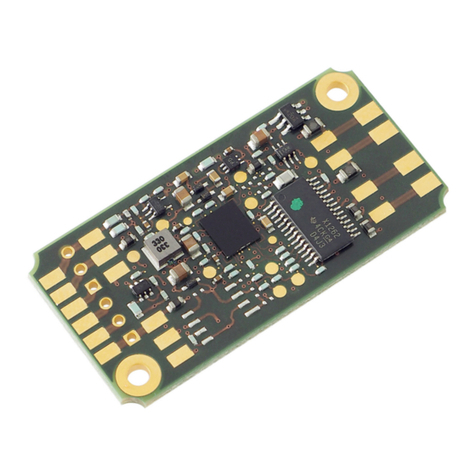

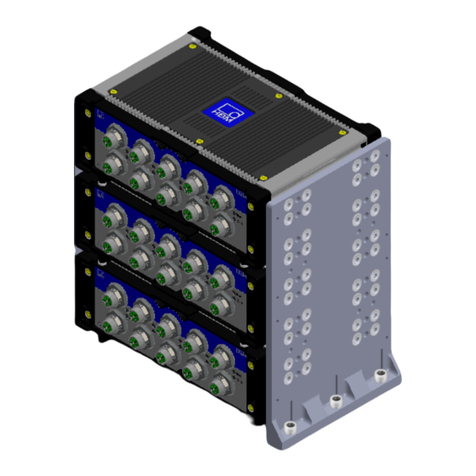

The MP70DP module and its connected transducers may be used for mea-

surement tasks only and directly related control tasks. To ensure safe opera-

tion, the transducer may only be used as specified in the operating manual. It

is also essential to follow the respective legal and safety regulations for the

application concerned during use. The same applies to the use of accesso-

ries.

Each time, before starting up the equipment, you must first run a project

planning and risk analysis that takes into account all the safety aspects of

automation technology. This particularly concerns personal and machine

protection.

Additional safety precautions must be taken in plants where malfunctions

could cause major damage, loss of data or even personal injury. In the event

of a fault, these precautions establish safe operating conditions.

This can be done, for example, by mechanical interlocking, error signaling,

limit value switches, etc.

General dangers due to non-observance of the safety instructions

The MP70DP module complies with the state of the art and is safe to operate.

If the equipment is used and operated inappropriately by untrained personnel,

residual dangers may arise.

Anyone responsible for installing, starting up, maintaining or repairing the

equipment needs to have read and understood the operating manual and in

particular the safety instructions.

Conditions on site

Protect the devices from moisture or atmospheric influences such as rain,

snow, etc.

Protect the device from direct sunlight. Ensure sufficient ventilation.

Maintenance and cleaning

The MP70DP module is maintenance-free. Please note the following points

when cleaning the housing:

−Before cleaning, disconnect the devices from the power supply.

−Clean the housing with a soft, slightly damp (not wet!) cloth. You should

never use solvent, since this could damage the labelling on the front panel

and the display.

−When cleaning, ensure that no liquid gets into the device or connections.