Change No. Created Responsible Released Version Rev. Sheet Page

C056927-05 Name Schäfer Schäfer Bauer D1215163 - 00 -

-01 10/

Serie Date 25.04.2017 25.04.2017 25.04.2017 Document no. 12

The reproduction, distribution and utilization of this document as well as the communication of its

contents to others without express authorization is prohibited. Offenders will be held liable for the

payment of damages. All rights reserved in the event of the grant of a patent, utility model or design.

The following values are to be checked and/or set:

Signal values Initial operation Fine adjustment Typical values*1)

Signal levels MA, MB(0°, 90°)*2) 0.8 …1.2 Vpp Not possible 0.6 …1.2 Vpp

Amplitude ratio MA / MB0.8 … 1.25 0.95 … 1.05 0.95 … 1.05 P5

Phase angle PHA 90° 10° 90° 5° 90° 3° P4

On-off ratio TVAand TVB

TV = 2 arcsin (|P - N| / M) 0° 15 ° 0° 5 ° 0° 3 ° P2 *3)

P3 *3)

Usable component G 0.2 …0.85 Vpp 0.2 …0.85 Vpp 0.2 …0.85 Vpp

Switching threshold E 0.2·G … 0.7·G 0.2·G … 0.7·G 0.2·G … 0.7·G

Zero crossovers K, L 180° 90° el. 180° 45° el. 180° 45° el. P1

(K-L) / 2 < 90° < 60° < 60° S1 *3)

*1) Typically, these values can be achieved by accurate mechanical mounting and fine adjustment by

potentiometers and DIP-switch. The values are valid up to 20% of the -3dB cut-off frequency in

permissible ranges of temperature, supply voltage and, mounting tolerances.

*2) Recommended signal level for lower fault detection limit 0.3 Vpp / upper fault detection limit 1.35 Vpp

*3) S1 is shifting the reference signal position in 90° steps. In consideration of the tolerance of the

Ref. signal, this allows to adjust the value |(K-L) / 2| < 60°. Depending on the setting of S1,

the Ref. signal is shifted and the allocation of TV1and TV2to P2 and P3 is as follows:

S1 setting

Ref. signal shift 0° -90° +90° 180°

TVx/ Px

allocation TV1= P2

TV2= P3 TV1= P3

TV2= P2 TV1= P3

TV2= P2 TV1= P2

TV2= P3

When reassembling the adapter connector, ensure that no cable wires are crimped.

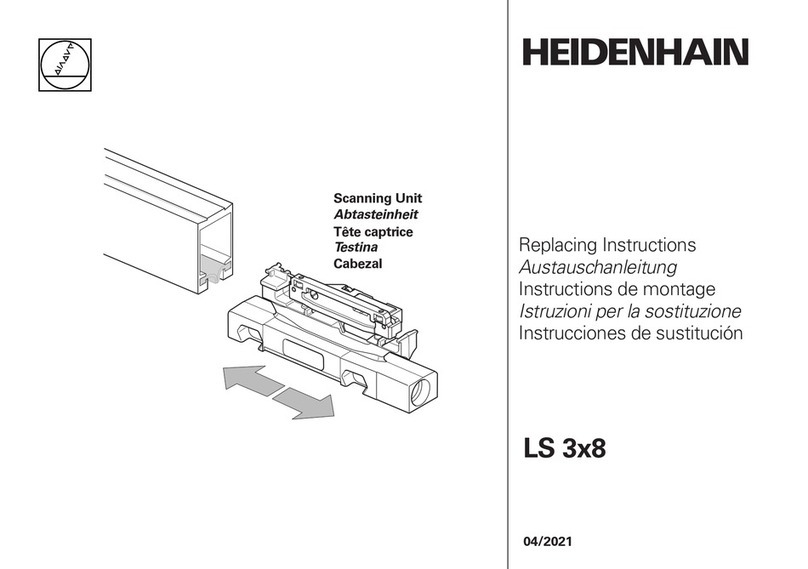

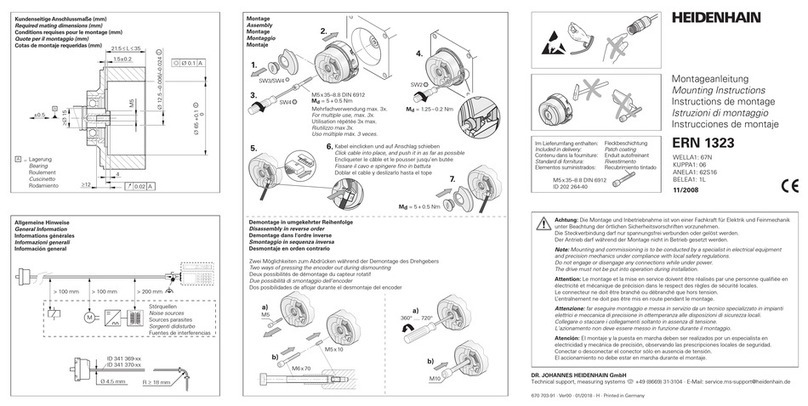

Figure 24: Assembly of the connector