- page 2 -

ITIC (CBEMA) curve

The ITIC curve judges the allowable level of

voltage RMS fluctuation from the voltage swell,

voltage dip and interruption events.

The analysis is made by the period and depth of

each event according to the limit value of the ITIC

curve.

The ITIC (Information Technology Industry

Council) curve is the most recent version of the

older CBEMA (Computer and Business

Equipment Manufacturers Association) curve.

Both were created by CBEMA. The original

CBEMA curve was widely used in the U.S.A.

Main Power Quality Parameters

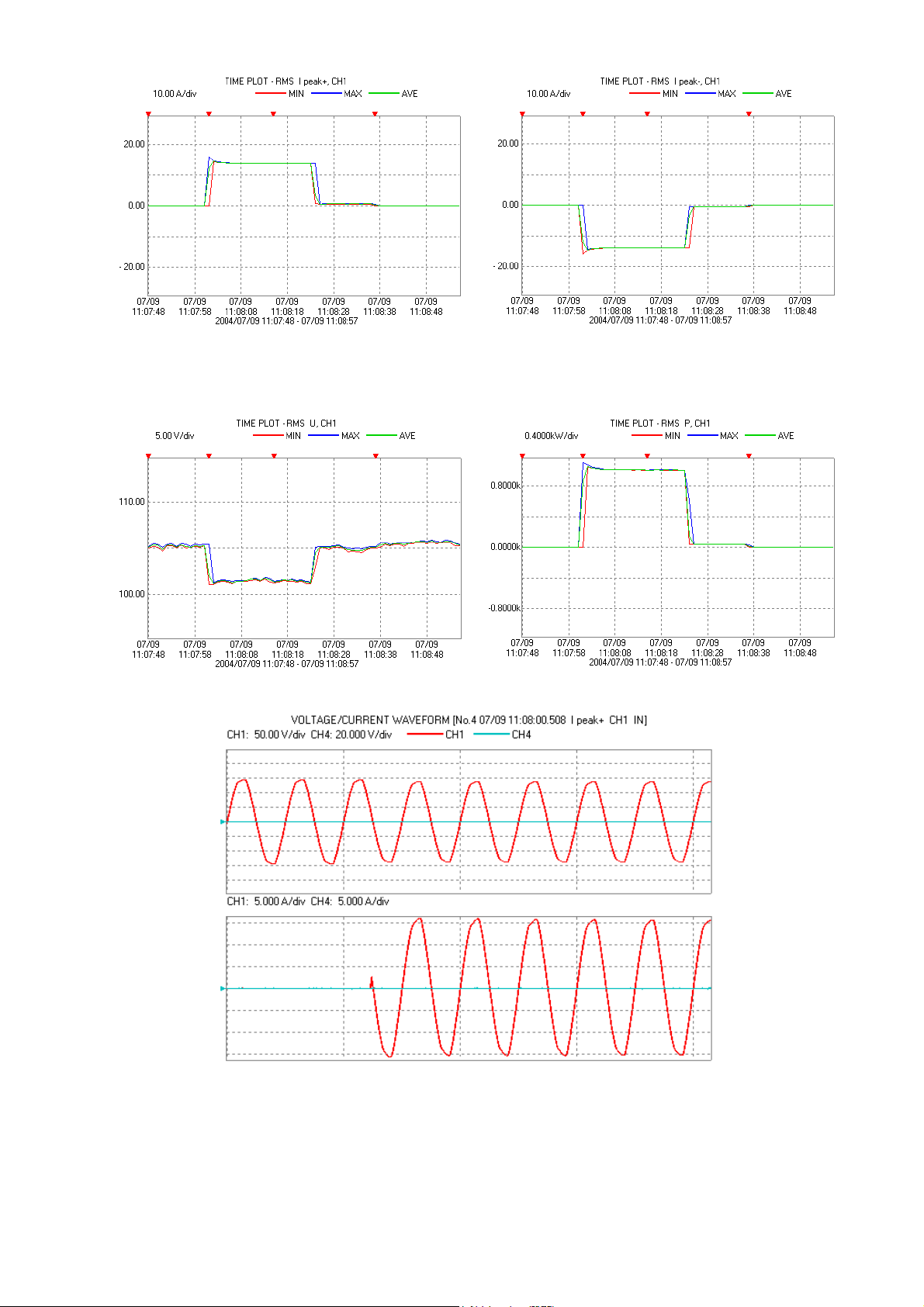

1. Transient overvoltage (impulse)

1) Phenomenon

Radical changes in voltage with high voltage

peaks

2) Cause

3) Damage

4) Analysis

Lightning strikes

Power circuit switching

Closure of inductive circuits

Arc to the ground

Load switching

Contact of a bouncing relay

Destruction of power supplies of

equipment

Equipment reset

Waveform (Maximum voltage level, Rise

time, Phase angle, Fluctuation,

Repeatability)

The faster rise time means a closer

occurring point.

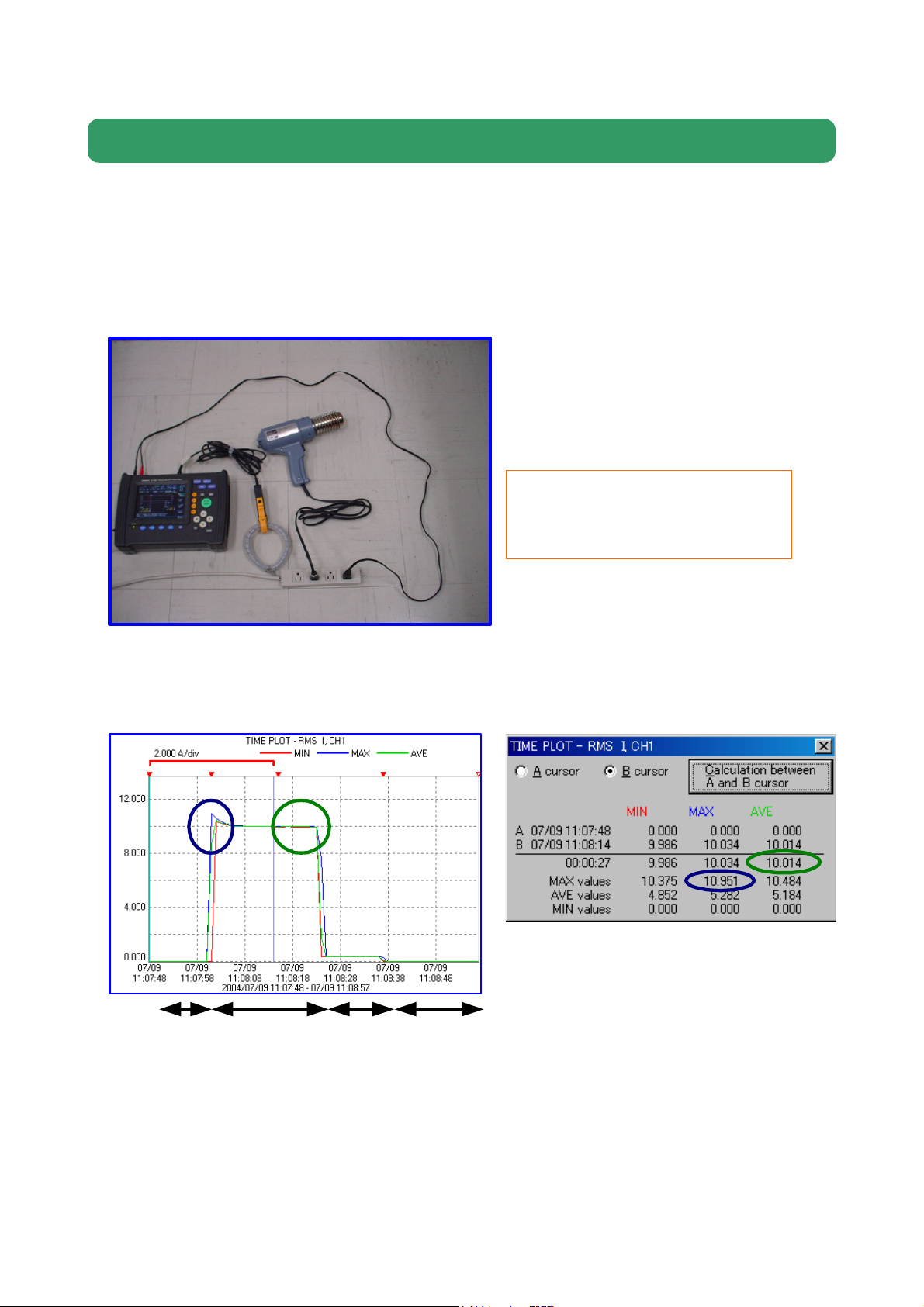

2. Voltage Dip

1) Phenomenon

Instantaneous drop of RMS voltage

2) Cause

3) Damage

Large inrush current by turning on heavy

loads

Accident in the distribution network

(Lightning, snow, ice, contact of birds/

trees, effects of accidents)

Short-circuit

Stop or equipment reset