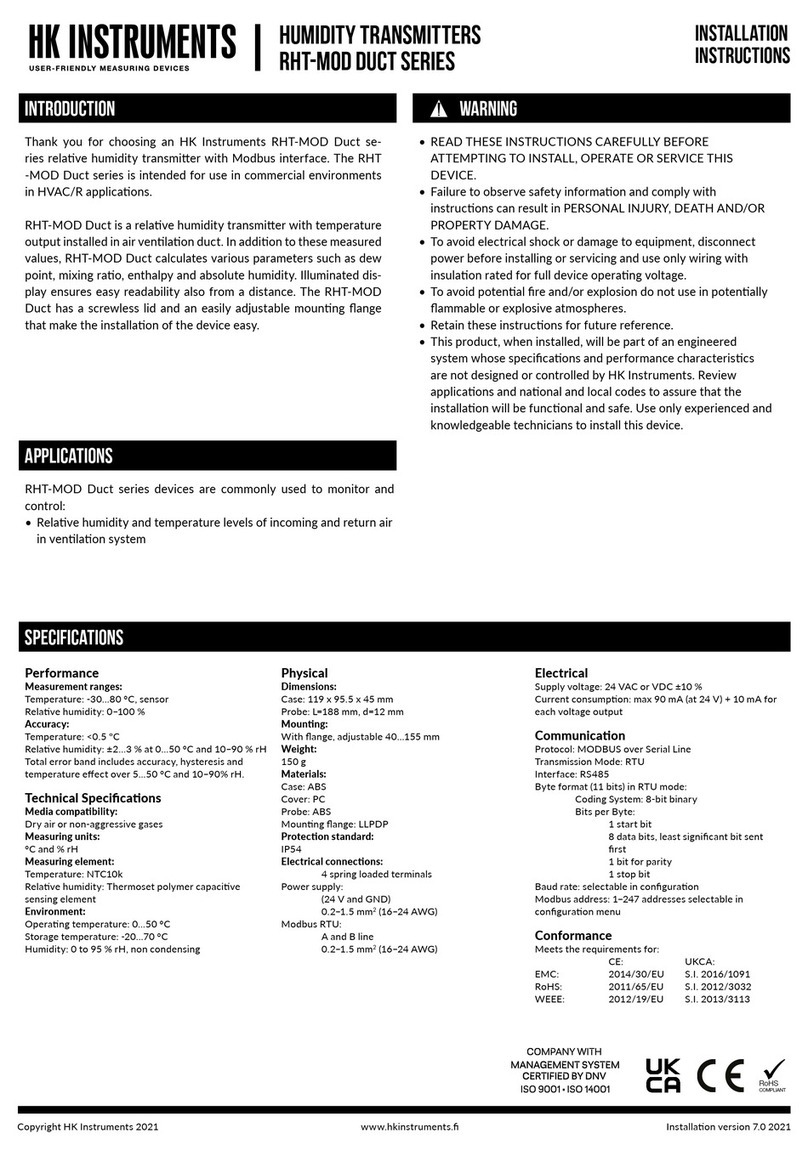

HK Instruments RHT Series User manual

Other HK Instruments Transmitter manuals

HK Instruments

HK Instruments RHT-MOD Duct Series User manual

HK Instruments

HK Instruments DPT-Dual-MOD Series User manual

HK Instruments

HK Instruments CDT2000 Series User manual

HK Instruments

HK Instruments CDT-MOD-2000 Series User manual

HK Instruments

HK Instruments DPT-Priima Series User manual

HK Instruments

HK Instruments DPT-Ctrl-MOD Series User manual

HK Instruments

HK Instruments DPT-2W- 100-R2 User manual

HK Instruments

HK Instruments DPT-R8 Series User manual

HK Instruments

HK Instruments CDT-MOD-2000 Duct Series User manual

HK Instruments

HK Instruments DPT-Flow Series User manual

HK Instruments

HK Instruments RHT-MOD Duct Series User manual

HK Instruments

HK Instruments DPT-IO-MOD Series User manual

HK Instruments

HK Instruments AVT Series User manual

HK Instruments

HK Instruments SIRO Series User manual

HK Instruments

HK Instruments DPT-Flow-1000 Quick start guide

HK Instruments

HK Instruments CMT Series User manual

HK Instruments

HK Instruments AVT Series User manual

HK Instruments

HK Instruments RHT-MOD Series User manual

HK Instruments

HK Instruments DPT-Dual-MOD Series User manual

HK Instruments

HK Instruments RHT-MOD Duct Series User manual

Popular Transmitter manuals by other brands

Camille Bauer

Camille Bauer KINAX 2W2 operating instructions

Emerson

Emerson Micro Motion 4700 installation manual

SICK STEGMANN

SICK STEGMANN MRA-F Series operating instructions

FISCHER

FISCHER DE61 instruction manual

Omega Engineering

Omega Engineering PHTX-11 Operator's manual

Xantech

Xantech HDTXSG01 installation instructions