Copyright HK Instruments 2019 www.hkinstruments. Installaon version 8.0 2019

INSTALLATION

INSTRUCTIONS

DIFFERENTIAL PRESSURE TRANSMITTERS

DPT-IO-MOD Series

• READ THESE INSTRUCTIONS CAREFULLY BEFORE

ATTEMPTING TO INSTALL, OPERATE OR SERVICE THIS

DEVICE.

• Failuretoobservesafetyinformaonandcomplywith

instruconscanresultinPERSONALINJURY,DEATHAND/OR

PROPERTY DAMAGE.

• Toavoidelectricalshockordamagetoequipment,disconnect

powerbeforeinstallingorservicinganduseonlywiringwith

insulaonratedforfulldeviceoperangvoltage.

• Toavoidpotenalreand/orexplosiondonotuseinpotenally

ammableorexplosiveatmospheres.

• Retaintheseinstruconsforfuturereference.

• Thisproduct,wheninstalled,willbepartofanengineered

systemwhosespecicaonsandperformancecharacteriscs

arenotdesignedorcontrolledbyHKInstruments.Review

applicaonsandnaonalandlocalcodestoassurethatthe

installaonwillbefunconalandsafe.Useonlyexperiencedand

knowledgeabletechnicianstoinstallthisdevice.

SPECIFICATIONS

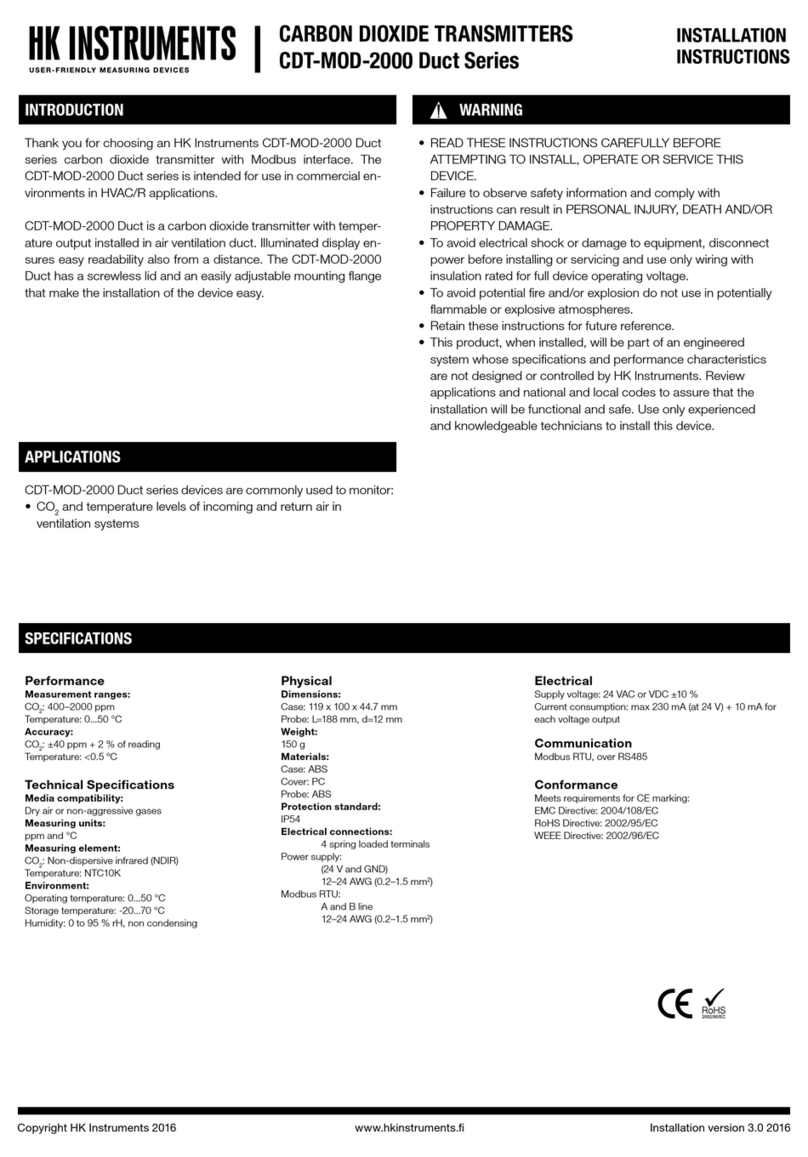

ThankyouforchoosinganHKInstrumentsDPT-IO-MODseriesdif-

ferenalpressure transmier. TheDPT-IO-MODdierenalpres-

suretransmierforairconformstoModbusoverseriallineprotocol,

usingRTUtransmissionmodeandRS485interface.Thedigitalout-

putsignalissentoverModbusenablingtheDPT-IO-MODtocon-

nectdirectlytoaeldcommunicaonsnetwork.

DPT-IO-MODrequireslesswiringthantradional3-wiretransmit-

ters,sincemulpledevicescanbeconnectedonserialline.

TheDPT-IO-MODincludesanInputterminalthatenablesreading

ofmulpleothersignalssuchastemperatureorcontrolrelaysover

Modbus.TheInputterminalhastwoinputchannelsdesignedtoac-

cept0−10V,NTC10k,Pt1000,Ni1000/(-LG),andBININ(potenal

free contact) signals. For example, DPT-IO-MOD can read values

fromonedierenalpressuremeasurementpointandtwotempera-

turemeasurementpoints.

DPT-IO-MODseriesdevicesarecommonlyusedinHVAC/R

systems for:

•fan,blowerandltermonitoring

•pressureandowmonitoring

•valveanddampercontrol

•pressuremonitoringincleanrooms

SPECIFICATIONS

Performance

Accuracy (from applied pressure):

Model2500:

Pressure<125Pa=1%+±2Pa

Pressure>125Pa=1%+±1Pa

Model7000:

Pressure<125Pa=1.5%+±2Pa

Pressure>125Pa=1.5%+±1Pa

(Including:generalaccuracy,linearity,hysteresis,long

termstabilityandrepeonerror)

Input accuracy:

<0,5%

Response me:

1...20sselectableviamenu

Overpressure:

Proofpressure:25kPa

Burstpressure:30kPa

Communicaon

Protocol:MODBUSoverSerialLine

TransmissionMode:RTU

Interface:RS485

Byteformat(11bits)inRTUmode:

CodingSystem:8-bitbinary

BitsperByte:

1startbit

8databits,leastsignicantbitsent

rst

1bitforparity

1stopbit

Baudrate:selectableinconguraon

Modbusaddress:1−247addressesselectablein

conguraonmenu

Zeropointcalibraonopons:

•Manualpushbuonautozero

•ViaModbuswritecoil

Technical Specicaons

Media compability:

Dryairornon-aggressivegases

Measuring units:

Selectableviamenu(Pa,mbar,inchWC,mmWC,psi)

Measuring element:

MEMS,noow-through

Environment:

Operangtemperature:-20...+50°C

Temperaturecompensatedrange0...+50°C

Storagetemperature:-40...+70°C

Humidity:0to95%rH

Physical

Dimensions:

Case:102.0x71.5x36.0mm

Weight:

150g,withaccessories290g

Mounng:

2each4.3mmscrewholes,onesloed

Materials:

Case: ABS

Lid:PC

Pressure inlets: Brass

Ductconnectors:ABS

Tubing:PVC

Protecon standard:

IP54

Display:

2-linedisplay(12characters/line)

Line1:acvemeasurement

Line2:units

Electrical Connecons:

4+3springloadterminals,max1.5mm2

CableEntry:M20

Pressure ngs:

Maleø5,0mmand6,3mm

Electrical

Supply voltage:

24VACorVDC±10%

Power consumpon:

<1.3W

Output signal:

viaModbus

Input signals:

2xinput(0...10v,NTC10k,Pt1000,NI1000/(-LG),or

BININ)

Conformance

MeetsrequirementsforCEmarking:

EMCdirecve2014/30/EU

RoHSDirecve2011/65/EU

WEEEDirecve2012/19/EU

INTRODUCTION

APPLICATIONS

WARNING

COMPANY WITH

MANAGEMENT SYSTEM

CERTIFIED BY DNV GL

RoHS 2