Copyright HK Instruments 2014 www.hkinstruments. Installation version 2.0 2014

INSTALLATION

INSTRUCTIONS

AIR FLOW AND VELOCITY TRANSMITTERS

AVT Series

INTRODUCTION

Thank you for choosing an HK Instruments AVT series air veloc-

ity transmitter. The AVT series is intended for use in commercial

environments. It is designed with a duct mount probe and adjust-

able collar suitable for round or rectangular ducts. The AVT series

provides separate readings for air velocity and temperature.

The AVT series comes with three measurement ranges in a single

device (0–2, 0–10, 0–20 m/s). The AVT series is available with op-

tional display and relay.

APPLICATIONS

AVT series devices are commonly used in HVAC/R systems for:

• in-duct air flow and velocity monitoring

• in-duct temperature monitoring

• VAV applications

WARNING

• READ THESE INSTRUCTIONS CAREFULLY BEFORE

ATTEMPTING TO INSTALL, OPERATE OR SERVICE THIS

DEVICE.

• Failure to observe safety information and comply with

instructions can result in PERSONAL INJURY, DEATH AND/OR

PROPERTY DAMAGE.

• To avoid electrical shock or damage to equipment, disconnect

power before installing or servicing and use only wiring with

insulation rated for full device operating voltage.

• To avoid potential fire and/or explosion do not use in potentially

flammable or explosive atmospheres.

• Retain these instructions for future reference.

• This product, when installed, will be part of an engineered

system whose specifications and performance characteristics

are not designed or controlled by HK Instruments. Review

applications and national and local codes to assure that the

installation will be functional and safe. Use only experienced

and knowledgeable technicians to install this device.

Performance

Measurement ranges:

Velocity: Range: 0–2 m/s

Range: 0–10 m/s

Range: 0–20 m/s

Temperature: 0−50 °C

Accuracy:

Velocity: Range: 0...2 m/s:

<0.1 m/s + 5 % from reading

Range: 0...10 m/s:

<0.5 m/s + 5 % from reading

Range: 0...20 m/s:

<1.0 m/s + 5 % from reading

Temperature: <0,5 ºC (velocity > 0,5 m/s)

Technical Specifications

Media compatibility:

Dry air or non-aggressive gases

Measuring units:

m/s and °C

Measuring element:

Temperature: ntc10k

Velocity: Pt1000

Environment:

Operating temperature: 0...50 °C

Storage temperature: -20...70 °C

Humidity: 0 to 95 % rH, non-condensing

Physical

Dimensions:

Case : 90.0 x 95.0 x 36.0 mm

Probe: OD 10 mm, length 210 mm from bottom of the

cover

Immersion Length with Flange: Adjustable 50–180 mm

Weight:

220 g

Mounting:

2 screw holes, 4.0 mm

Materials:

Case: ABS

Lid: PC

Probe: Stainless steel 304

Mounting flange: LLPDP

Protection standard:

IP54

Display

3 1/2 digit LCD backlit display

Size: 45.7 x 12.7 mm

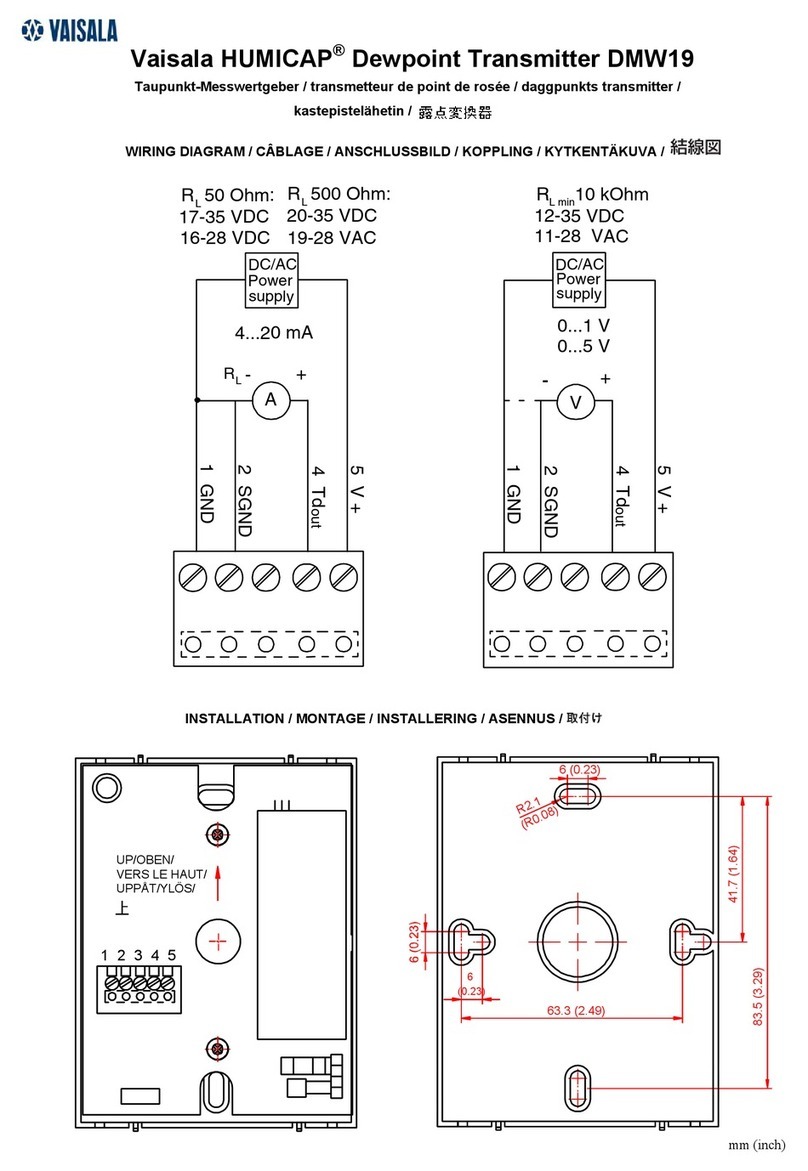

Electrical connections:

Power supply & signal out: 4-screw terminal block

12–24 AWG (0.2–1.5 mm2)

Relay Out: 3-screw terminal block

12-24 AWG (0.2–1.5 mm2)

Cable entry:

M16

Electrical

Input: 24 VDC / 24 VAC ± 10 %

Current consumption 35 mA (50 mA with relay)

+ 40 mA with mA-outs

Output signal 1: (T out)

0–10 V (linear to temperature)

L min 1 kΩ

4–20 mA (linear to temperature)

L max 400 Ω

Output signal 2: (v out)

0–10 V (linear to m/s)

L min 1 kΩ

4–20 mA (linear to m/s)

L max 400 Ω

Relay Out: 3-screw terminal block

(NC, COM, NO)

12–24 AWG (0.2–1.5 mm2)

Potential free SPDT

250 VAC, 6A / 30 VDC, 6 A adjustable switching point

and hysteresis

Conformance

Meets the requirements for CE marking:

EMC Directive 2004/108/EC

RoHS Directive 2002/95/EC

LVD Directive 2006/95/EC

WEEE Directive 2002/96/EC

SPECIFICATIONS