HK Instruments RHT-MOD Duct Series User manual

Other HK Instruments Transmitter manuals

HK Instruments

HK Instruments DPT-Dual-MOD Series User manual

HK Instruments

HK Instruments Siro-MOD Series User manual

HK Instruments

HK Instruments DPT-MOD Series User manual

HK Instruments

HK Instruments RHT-MOD Duct Series User manual

HK Instruments

HK Instruments CDT-MOD-2000 Series User manual

HK Instruments

HK Instruments DPT-MOD Series User manual

HK Instruments

HK Instruments CDT Series User manual

HK Instruments

HK Instruments DPT-CR-MOD Series User manual

HK Instruments

HK Instruments CMT Series User manual

HK Instruments

HK Instruments CDT-MOD-2000 Duct Series User manual

HK Instruments

HK Instruments DPT-Ctrl-MOD Series User manual

HK Instruments

HK Instruments DPT-Priima Series User manual

HK Instruments

HK Instruments DPT Series User manual

HK Instruments

HK Instruments DPT-Dual-MOD Series User manual

HK Instruments

HK Instruments DPT-MOD Series User manual

HK Instruments

HK Instruments DPT-2W- 100-R2 User manual

HK Instruments

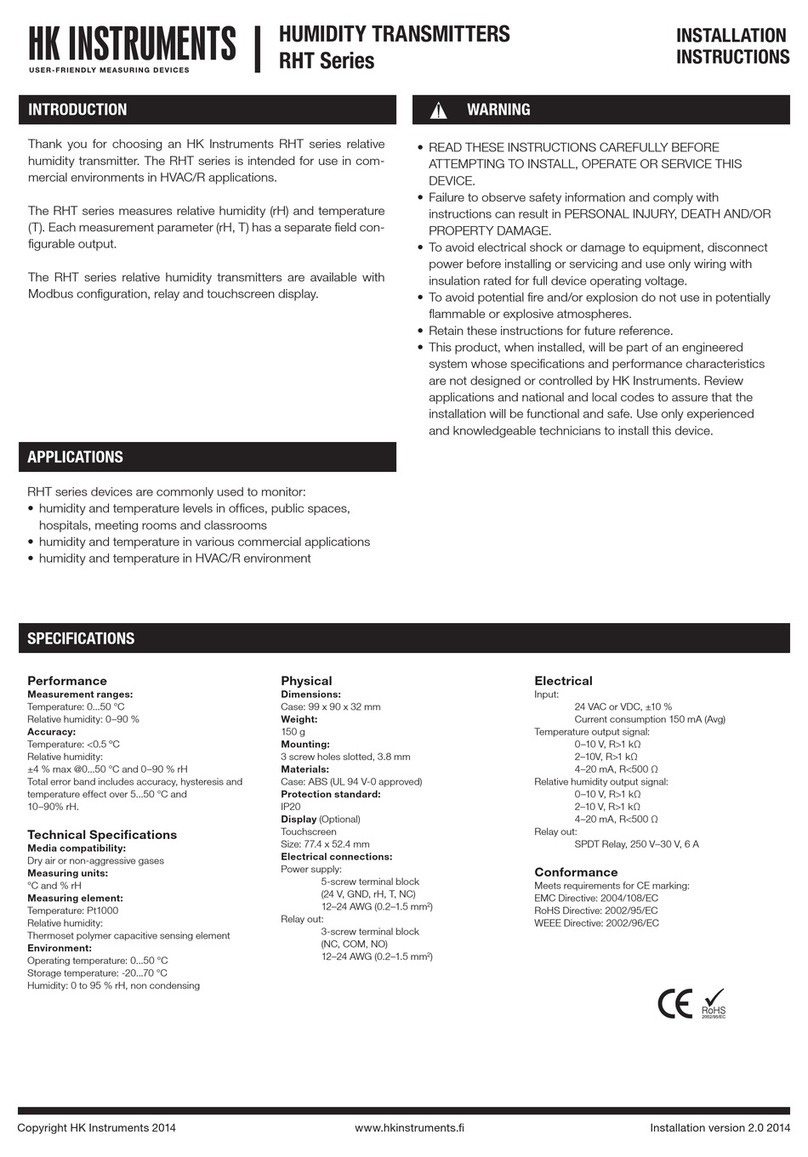

HK Instruments RHT Series User manual

HK Instruments

HK Instruments DPT-Flow-1000 Quick start guide

HK Instruments

HK Instruments DPT-Priima Series User manual

HK Instruments

HK Instruments CDT2000 Series User manual

Popular Transmitter manuals by other brands

MTS Sensors

MTS Sensors Level Plus M Series Operation and installation manual

ABB

ABB 6X1EH operating instructions

YOKOGAWA

YOKOGAWA Dpharp EJ 510 Series user manual

Beyerdynamic

Beyerdynamic Synexis TP8 Product information

ATIM

ATIM Cloud Wireless DINRS user guide

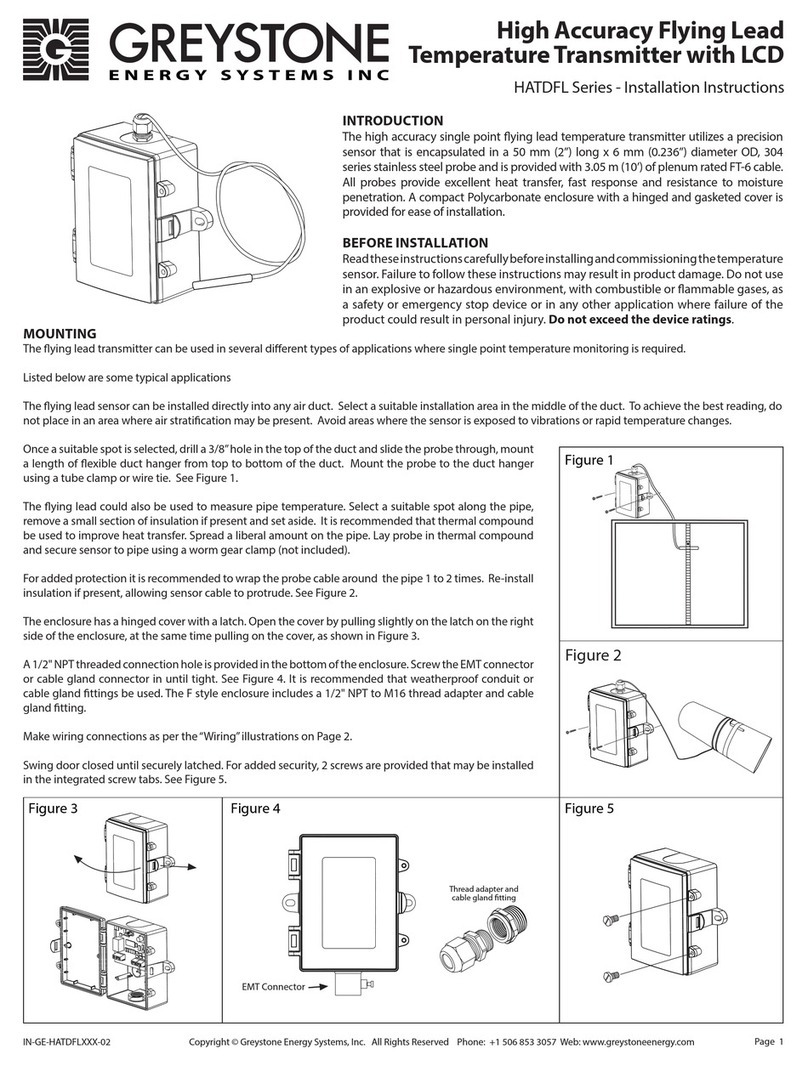

Greystone Energy Systems

Greystone Energy Systems HATDFL Series installation instructions