Copyright HK Instruments 2014 www.hkinstruments. Installation version 1.0 2014

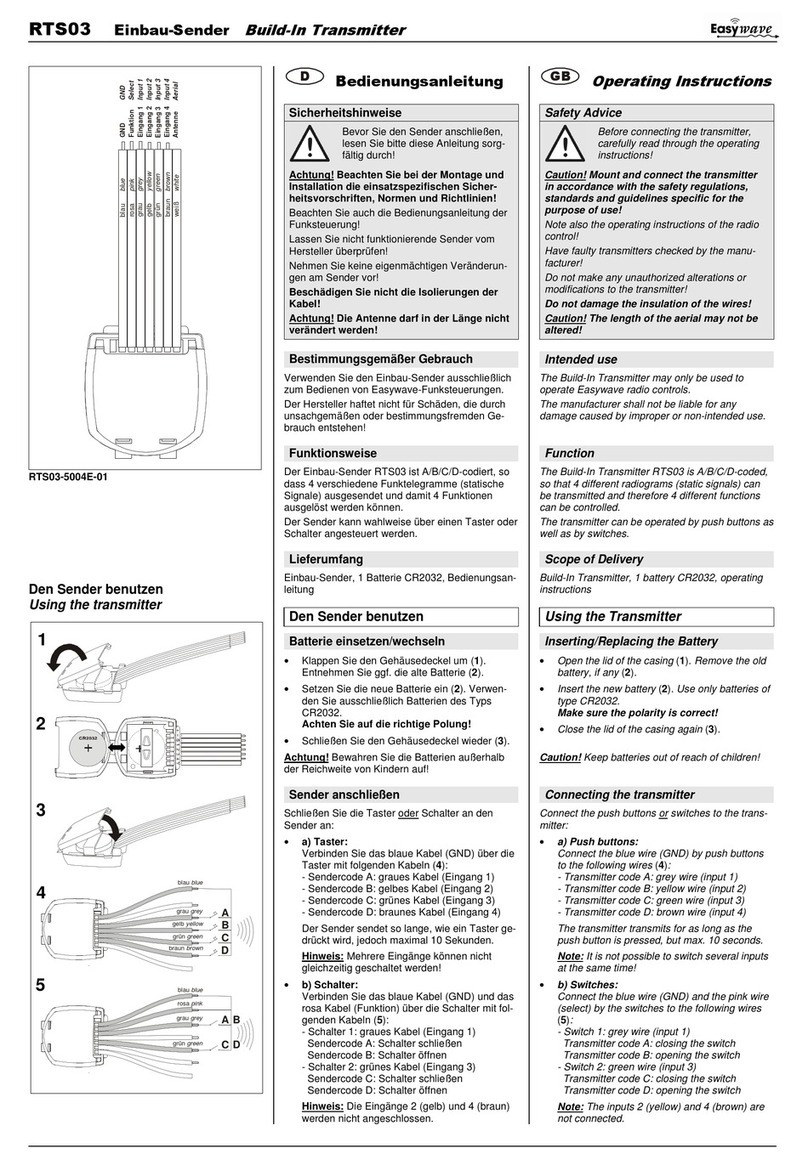

INSTALLATION

INSTRUCTIONS

DIFFERENTIAL PRESSURE TRANSMITTERS

DPT-Dual-MOD Series

WARNING

• READTHESEINSTRUCTIONSCAREFULLYBEFORE

ATTEMPTINGTOINSTALL,OPERATEORSERVICETHIS

DEVICE.

• Failuretoobservesafetyinformationandcomplywith

instructionscanresultinPERSONALINJURY,DEATHAND/OR

PROPERTYDAMAGE.

• Toavoidelectricalshockordamagetoequipment,disconnect

powerbeforeinstallingorservicinganduseonlywiringwith

insulationratedforfulldeviceoperatingvoltage.

• Toavoidpotentialreand/orexplosiondonotuseinpotentially

ammableorexplosiveatmospheres.

• Retaintheseinstructionsforfuturereference.

• Thisproduct,wheninstalled,willbepartofanengineered

systemwhosespecicationsandperformancecharacteristics

arenotdesignedorcontrolledbyHKInstruments.Review

applicationsandnationalanlocalcodestoassurethatthe

installationwillbefunctionalandsafe.Useonlyexperienced

andknowledgeabletechnicianstoinstallthisdevice.

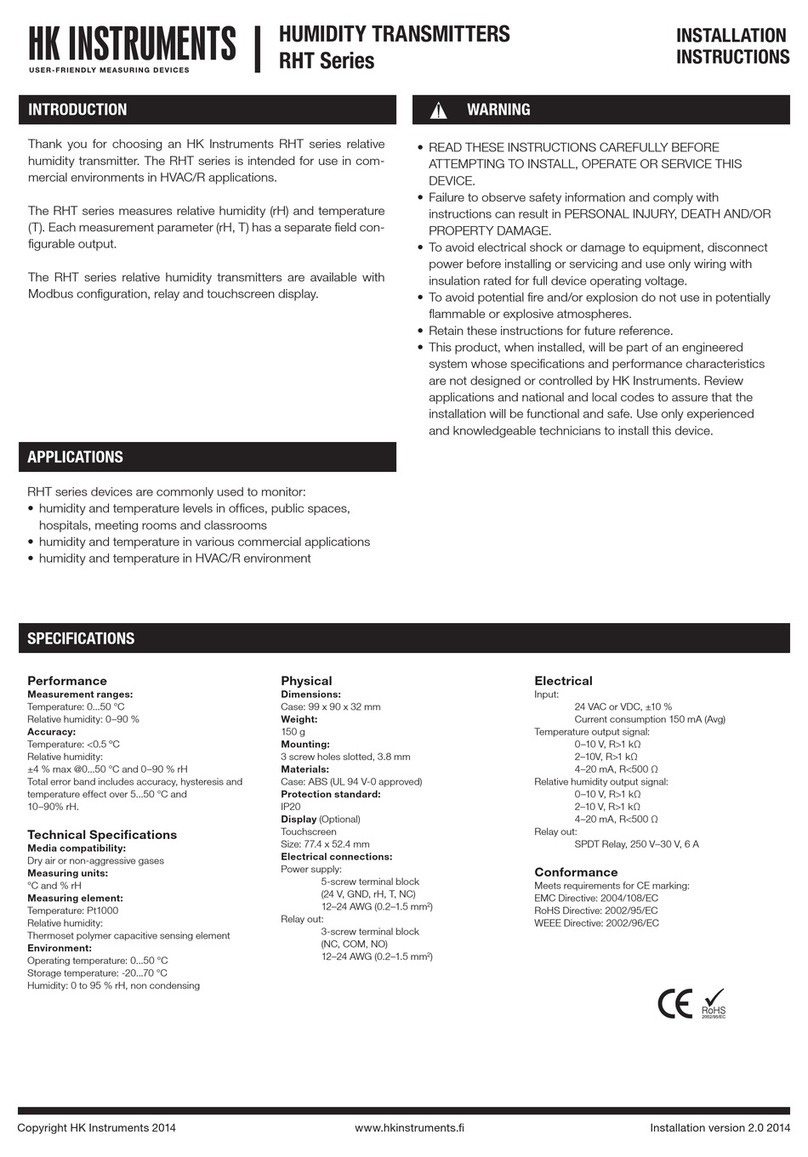

SPECIFICATIONS

INTRODUCTION

Thank you for choosing an HK Instruments DPT-Dual-MOD se-

ries differential pressure transmitter. DPT-Dual-MOD combines

two differential pressure transmitters into one device. It offers a

possibilitytomeasurepressurefromtwodifferentpoints.Ithasa

ModbusinterfaceandanInputterminal.WhenusingtheInputter-

minal,temperaturetransmitterscanbereplacedwithtemperature

sensors.Asaresultyouwillsaveincostsofthedevicesandinthe

installationcosts.

APPLICATIONS

DPT-Dual-MODseriesdevicesarecommonlyusedinHVAC/R

systemsfor:

•fan,blowerandltermonitoring

•pressureandowmonitoring

•valveanddampercontrol

•pressuremonitoringincleanrooms

SPECIFICATIONS

Performance

Accuracy(fromappliedpressure):

±1.5%+1Pa

(Including:generalaccuracy,temperaturedrift,linearity,

hysteresis,longtermstabilityandrepetitionerror)

Response time:

1...20sselectableviamenu

Max pressure:

400kPa

Communication

Protocol:MODBUSoverSerialLine

TransmissionMode:RTU

Interface:RS485

Byteformat(11bits)inRTUmode:

CodingSystem:8-bitbinary

BitsperByte:

1startbit

8databits,leastsignicantbitsentrst

1bitforparity

1stopbit

Baudrate:selectableinconguration

Modbusaddress:1−247addressesselectablein

congurationmenu

Zero point calibration options:

•Manualpushbuttonautozero

•ViaModbuswritecoil

ResponseTime:

0.8sec,2.0sec,or10secselectableinconguration

menu

Technical Specifications

Media compatibility:

Dryairornon-aggressivegases

Measuring units on display:

Selectableviamenu(Pa,mbar,inchWC,mmWC,psi)

Measuring element:

Piezoresistive

Environment:

Operatingtemperature:-10...+50°C

Storage temperature: -20...+70 °C

Humidity: 0 to 95 % rH

Physical

Dimensions:

Case: 102.0x71.5x36.0mm

Weight:

150g,withaccessories290g

Mounting:

2each4.3mmscrewholes,oneslotted

Materials:

Case:ABS

Lid:PC

Protection standard:

IP54

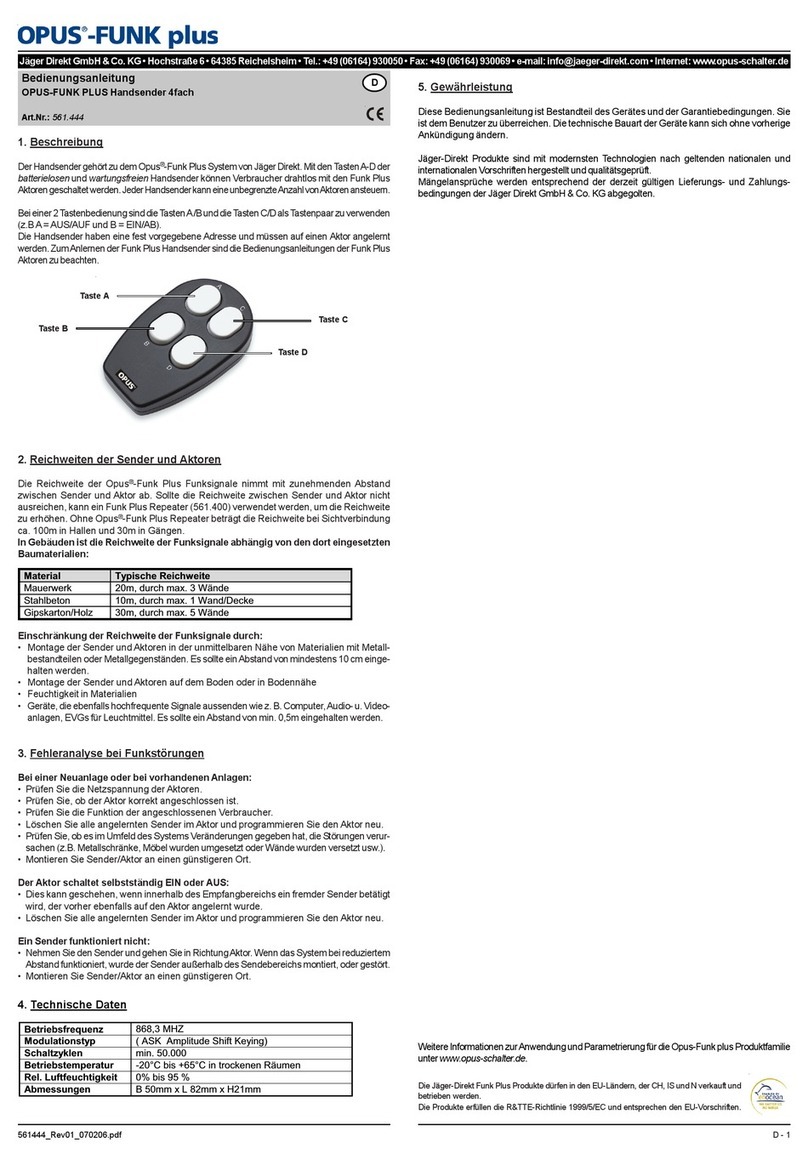

Display:

2-line display (12 characters/line)

Line 1: active measurement, inlet A

Line 2: active measurement, inlet B

Electrical Connections:

4+3springloadterminals,max1.5mm2

CableEntry:M20

Pressure connections:

Male 5,0 mm and 6,3 mm

Electrical

Supply voltage:

24VACorVDC±10%

Power consumption:

<1.3W

Output signal:

viaModbus

Conformance

MeetsrequirementsforCEmarking:

EMCdirective2004/108/EC

RoHSDirective2002/95/EC