Copyright HK Instruments 2014 www.hkinstruments. Installation version 2.0 2014

The seller is obligated to provide a warranty of 24 months for the de-

livered goods regarding material and manufacturing. The warranty

period is considered to start on the delivery date of the product. If

a defect in raw materials or a production flaw is found, the seller is

obligated, when the product is sent to the seller without delay or be-

fore expiration of the warranty, to amend the mistake at his/her dis-

cretion either by repairing the defective product or by delivering free

of charge to the buyer a new flawless product and sending it to the

buyer. Delivery costs for the repair under warranty will be paid by the

buyer and the return costs by the seller. The warranty does not com-

prise damages caused by accident, lightning, flood or other natural

phenomenon, normal wear and tear, improper or careless handling,

abnormal use, overloading, improper storage, incorrect care or re-

construction, or changes and installation work not done by the seller

or his/her authorized representative. The selection of materials for de-

vices prone to corrosion is the buyer’s responsibility, unless otherwise

is legally agreed upon. Should the manufacturer alter the structure of

the device, the seller is not obligated to make comparable changes to

devices already purchased. Appealing for warranty requires that the

buyer has correctly fulfilled his/her duties arisen from the delivery and

stated in the contract. The seller will give a new warranty for goods

that have been replaced or repaired within the warranty, however only

to the expiration of the original product’s warranty time. The warranty

includes the repair of a defective part or device, or if needed, a new

part or device, but not installation or exchange costs. Under no cir-

cumstance is the seller liable for damages compensation for indirect

damage.

2) Autozero calibration

If the device includes the optional autozero circuit, no action is re-

quired.

Autozero calibration (-AZ) is an autozero function in the form of an au-

tomatic zeroing circuit built into the PCB board. The autozero calibra-

tion electronically adjusts the transmitter zero at predetermined time

intervals (every 10 minutes). The function eliminates all output signal

drift due to thermal, electronic or mechanical effects, as well as the

need for technicians to remove high and low pressure tubes when

performing initial or periodic transmitter zero point calibration. The au-

tozero adjustment takes 4 seconds after which the device returns to

its normal measuring mode. During the 4 second adjustment period,

the output and display values will freeze to the latest measured value.

Transmitters equipped with the autozero calibration are virtually

maintenance free.

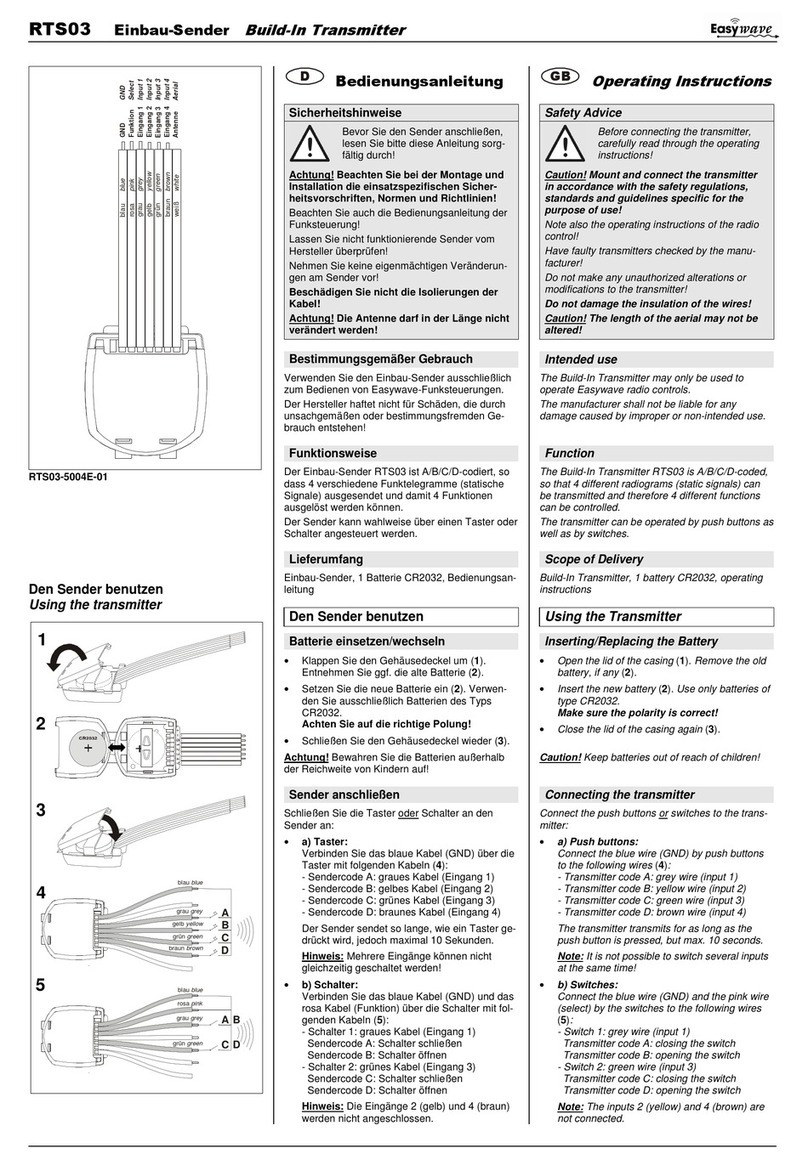

a) Disconnect both pressure tubes from the pressure ports labeled

+ and –.

b) Push down the zero button (joystick) until the LED light (red)

turns on and the display reads “zeroing” (display option only). (see

Figure 6)

c) The zeroing of the device will proceed automatically. Zeroing is

complete when the LED turns off, and the display reads 0 (display

option only).

d) Reinstall the pressure tubes, ensuring the High pressure tube is

connected to the port labeled +, and the Low pressure tube is

connected to the port labeled −.

Press down button

LED turns ON

Display reads “Zeroing”

LED

Figure 4

To zero the device two options are available:

1) Manual Pushbutton zero point calibration

2) Autozero calibration

Does my transmitter have an autozero calibration? See the product

label. If it shows -AZ in the model number, then you have the au-

tozero calibration.

1) Manual Pushbutton zero point calibration

NOTE: Supply voltage must be connected at least one hour prior to

zero point adjustment.

a) Disconnect both pressure tubes from the pressure ports labeled

+ and –.

b) Push down the zero button until the LED light (red) turns on and

the display reads “zeroing” (display option only). (see Figure 4)

c) The zeroing of the device will proceed automatically. Zeroing

is complete when the LED turns off, and the display reads 0

(display option only).

d) Reinstall the pressure tubes ensuring that the High pressure

tube is connected to the port labeled +, and the Low pressure

tube is connected to the port labeled −.

STEP 7: ZEROING THE DEVICE

The response time affects how fast the transmitter reacts to changes

in the system. The response time is the time the device takes to

reach half of the change in the measured value. To smooth out

unstable pressure fluctuations in airflow applications, select longer

response time.

Example:

Selected response time: 4.0 seconds

Selected measurement unit: inWC

Change in the system: increase of ∆P1= 2

Result: Output signal = ∆P2= 1, in 4.0 seconds after the change in

the system (½ ∆P1= ∆P2= 1)

To change response time, install or remove jumper on J4.

(see Figure 5)

1) Install jumper on J4 for 4.0 second response time.

2) Remove jumper from J4 for 0.8 second response time.

SELECTING THE MEASUREMENT RANGE CONTINUED

WARRANTY POLICY

STEP 6: SELECTING THE RESPONSE TIME

ZEROING THE DEVICE CONTINUED

Range 7 Range 8Range 1 Range 2 Range 3 Range 4 Range 5 Range 6

Jumper J1

Jumper J2

Jumper J3

(Grey colour indicates that a jumper is installed. Reference Figure 3 and Schematics for jumper installation.)

Chart 2