ADEMCO 4204 Relay Module – Installation Instructions

GENERAL INFORMATION

The ADEMCO 4204 Relay Module provides from one to four

dry, form-C (SPDT) relay outputs to compatible

control/communicators. It connects to the control’s keypad

wiring terminals.

The 4204 can be mounted inside the control’s cabinet or

mounted remotely depending on the application. Refer to the UL

notes below for certain restrictions.

If mounted remotely, the 4204 has a built-in tamper switch that

allows it to detect and report the removal of its cover to the

control. Second, communication to the 4204 is supervised so

that it cannot be disconnected from the keypad wiring without

detection by the control. If the wiring is cut, a tamper or alarm

signal will result, to indicate that this device (and possibly other

devices connected to the keypad wiring) has become

inoperative.

INSTALLATION

For UL Installations:

When used with controls that do not support cover tamper or

supervise communications wiring to the 4204, mount the 4204

inside the control’s cabinet.

When used with controls that support cover tamper and

supervise communications wiring to the 4204, mount the 4204

may either be mounted inside the control’s cabinet or mounted

remotely.

NOTE: The maintenance instructions shall detail all test

and maintenance instruction codes and software

necessary to provide test and inspection requirements

of CAN/ULC-S536, Standard for the Inspection and

Testing of Fire Alarm Systems

When mounted inside the control’s cabinet, some controls allow

the 4204 to be mounted horizontally as follows: insert the self-

tapping screws (provided) in two adjacent raised tabs on the

back of the cabinet. Leave the heads projecting 1/8”. Hang the

4204 on the screw heads via two of the slotted holes on the

back of its housing. The 4204’s cover need not, in this case, be

tamper-protected. Set DIP switch 1 to “ON” if the cover is not

used (see table). See the control’s instructions for additional

information.

When the 4204 is mounted remotely, it can be mounted

horizontally or vertically and the built-in tamper switch can be

used. Wires can exit from the side or via the breakout on the

back of its housing. The DIP switch must be set with its position

1 “OFF” and when the installation is completed, the unit’s

tamper-protected cover must be replaced.

NOTE: For EN50131-3 compliance a tie-wrap must be secured

around the case of a remotely mounted 4204.

Apply tie-wrap around the case to the right of the large zone

wire opening (4-inch case width). This is in opposition of the

tamper switch and magnet.

NOTE: CE installations require maximum cable length of 30

meters.

Affix the connections label that accompanies the 4204 to the

inside of the 4204’s cover (if the cover is used) or to the inside of

the control’s cover.

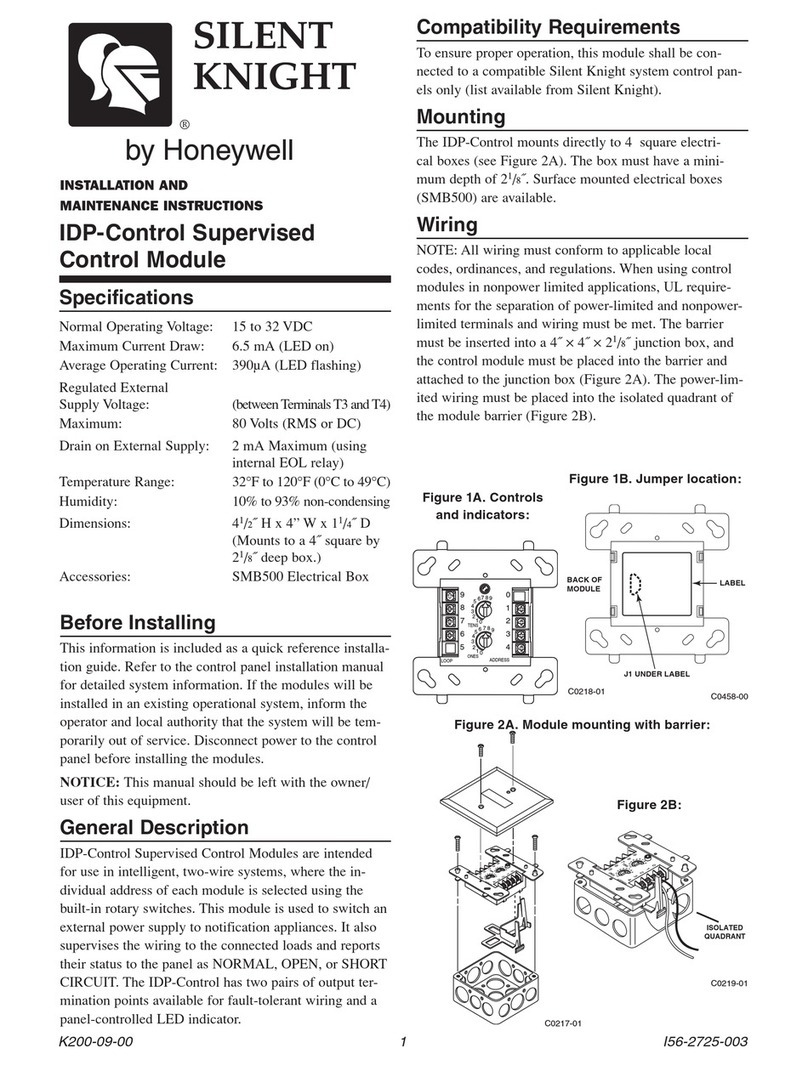

CONNECTIONS AND SETTINGS

Select and set an address for the 4204, using its DIP switch as

shown in the DIP switch table. Each 4204 must be assigned a

unique address so the control can identify and communicate

with the 4204. The address to set is determined by the

particular control to be used. See the control’s installation

instructions. As shipped, the DIP switch is set for address “0”.

UL

For UL fire installations, no more than

one wire per terminal may be

connected.

•Use only 14-22AWG wire.

NOTE: All power-limited wiring must be separated from non-

power limited wiring by ¼”.

Make connections to the 4204’s four relays via 12-position

terminal block TB2. Refer to the control’s installation

instructions for specific information on how to program the

activation options for the relays.

Make connections to the control’s keypad wiring points via 4-

position terminal block TB1, the 4-pin plug, or both (wire color

connections are the same). See the diagram on the other side

of this page.

SPECIFICATIONS

Physical: 6-7/16” W x 4-1/4” H x 1-1/4” D

(163mm x 108mm x 32mm)

Electrical:

control’s remote keypad connection

points)

15mA standby + 40mA per active relay

2A max. at 28VDC/AC (resistive loads)

UL

For dry, indoor use only. Do not install in air-

handling spaces.

•For UL Commercial Burglary installations, the

4204 must be tamper protected or mounted in

a tamper-protected cabinet.

•In Commercial Fire applications, the module

cannot be mounted in the control unit’s

cabinet, but must be mounted in an external

UL864-listed cabinet.