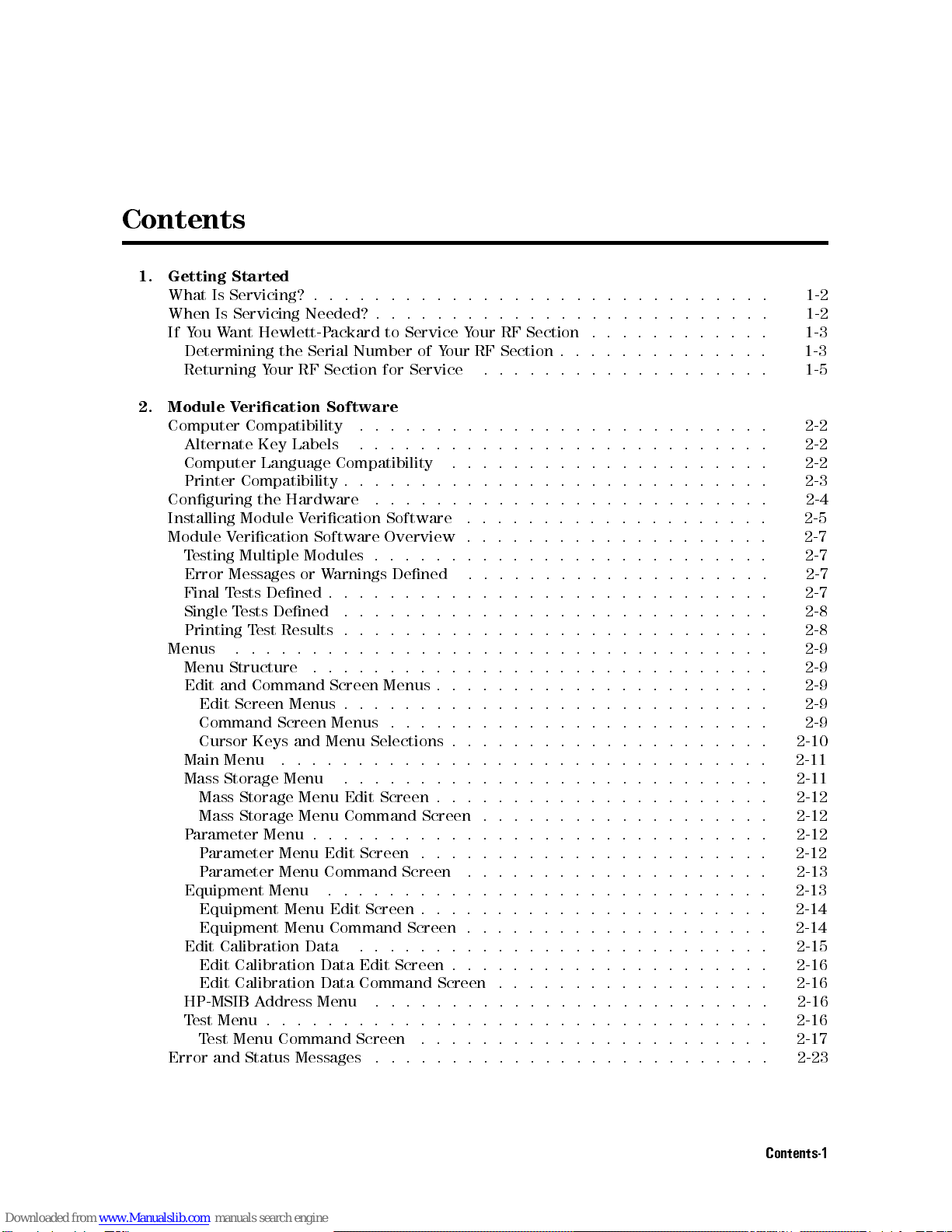

Contents

1. Getting Started

What Is Servicing? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

When Is Servicing Needed? . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

If You Want Hewlett-Packard to Service Your RF Section . . . . . . . . . . . . 1-3

Determining the Serial Number of Your RF Section . . . . . . . . . . . . . . 1-3

Returning Your RF Section for Service ................... 1-5

2. Module Verication Software

Computer Compatibility ........................... 2-2

Alternate Key Labels .. .. .. .. .. .. .. .. .. .. .. .. .. . 2-2

Computer Language Compatibility ..................... 2-2

Printer Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Conguring the Hardware .. .. .. .. .. .. .. .. .. .. .. .. .. 2-4

Installing Module Verication Software .................... 2-5

Module Verication Software Overview . . . . . . . . . . . . . . . . . . . . 2-7

Testing Multiple Modules . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Error Messages or Warnings Dened .... .. .. .. .. .. . .. .. . 2-7

Final Tests Dened . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Single Tests Dened .... .. .. .. .. .. .. .. . .. .. .. .. . 2-8

Printing Test Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Menus ................................... 2-9

Menu Structure .............................. 2-9

Edit and Command Screen Menus . . . . . . . . . . . . . . . . . . . . . . 2-9

Edit Screen Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Command Screen Menus . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Cursor Keys and Menu Selections . . . . . . . . . . . . . . . . . . . . . 2-10

Main Menu ................................ 2-11

Mass Storage Menu .... .. .. .. .. .. .. .. .. .. . .. .. . 2-11

Mass Storage Menu Edit Screen . . . . . . . . . . . . . . . . . . . . . . 2-12

Mass Storage Menu Command Screen . . . . . . . . . . . . . . . . . . . 2-12

Parameter Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Parameter Menu Edit Screen . . . . . . . . . . . . . . . . . . . . . . . 2-12

Parameter Menu Command Screen .... .. .. .. .. .. .. .. .. 2-13

Equipment Menu ............................. 2-13

Equipment Menu Edit Screen . . . . . . . . . . . . . . . . . . . . . . . 2-14

Equipment Menu Command Screen . . . . . . . . . . . . . . . . . . . . 2-14

Edit Calibration Data .... .. .. .. .. .. .. .. . .. .. .. .. 2-15

Edit Calibration Data Edit Screen . . . . . . . . . . . . . . . . . . . . . 2-16

Edit Calibration Data Command Screen . . . . . . . . . . . . . . . . . . 2-16

HP-MSIB Address Menu .......................... 2-16

Test Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

Test Menu Command Screen .... .. .. .. .. .. .. .. .. .. . 2-17

Error and Status Messages .......................... 2-23

Contents-1