HP 11729B

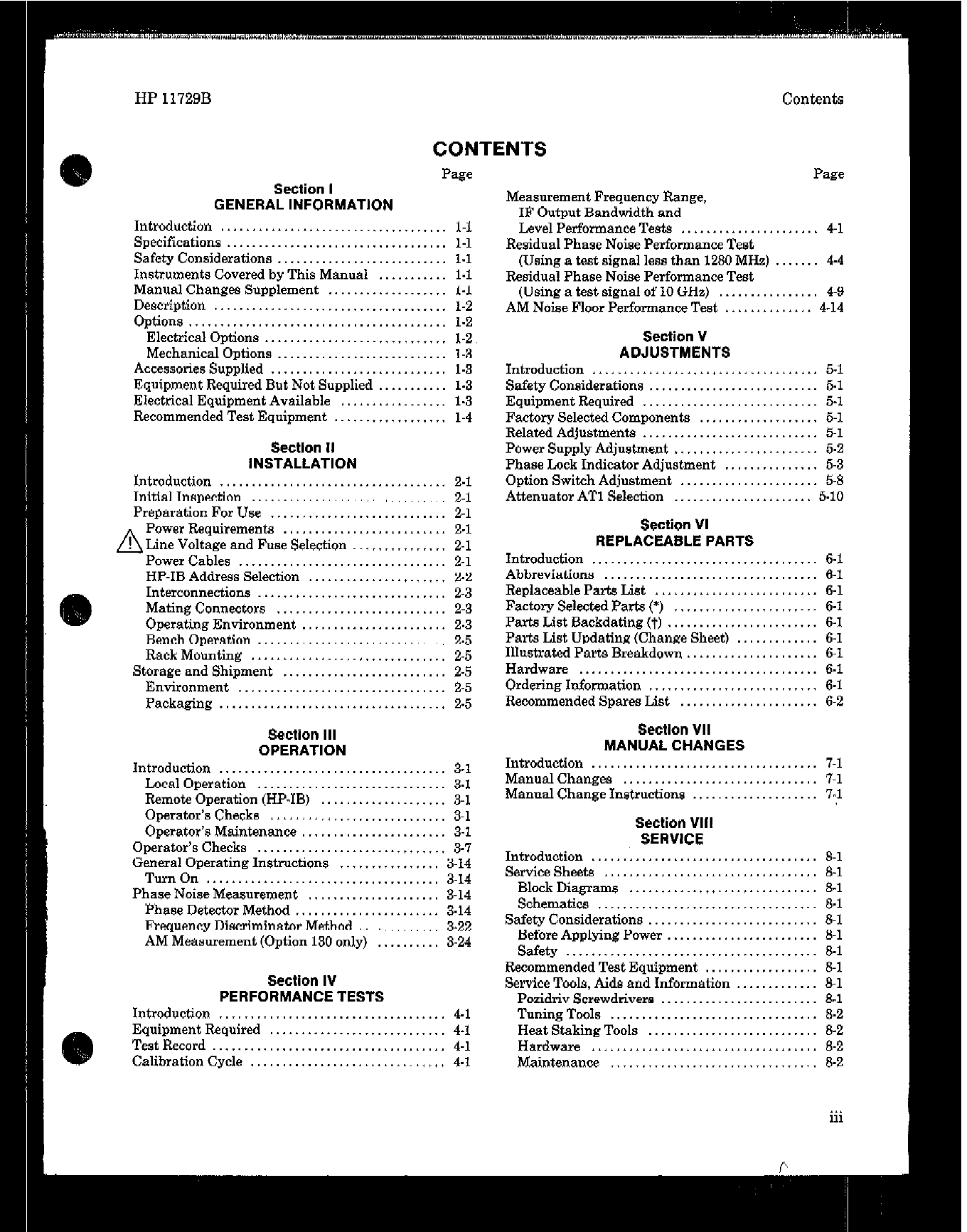

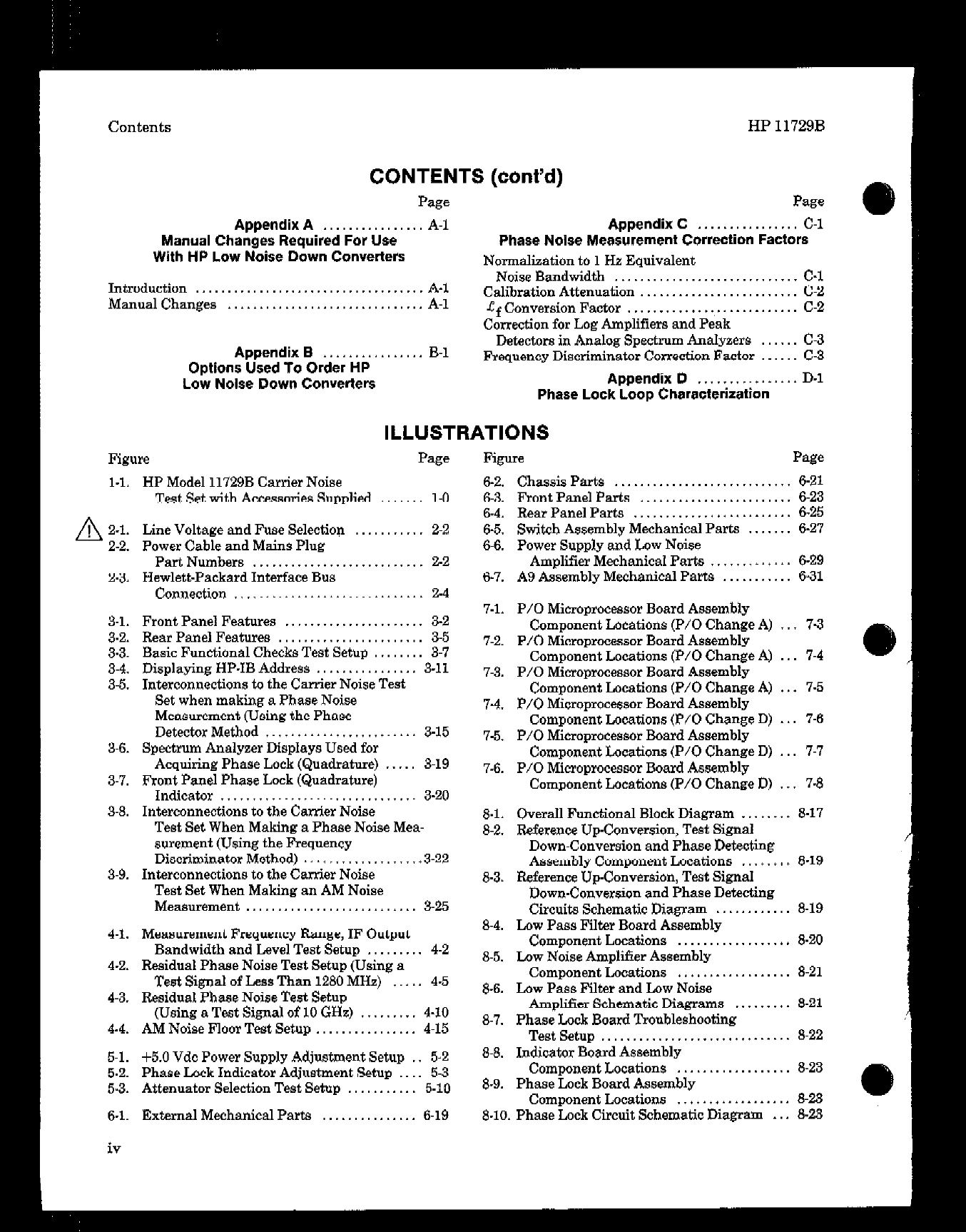

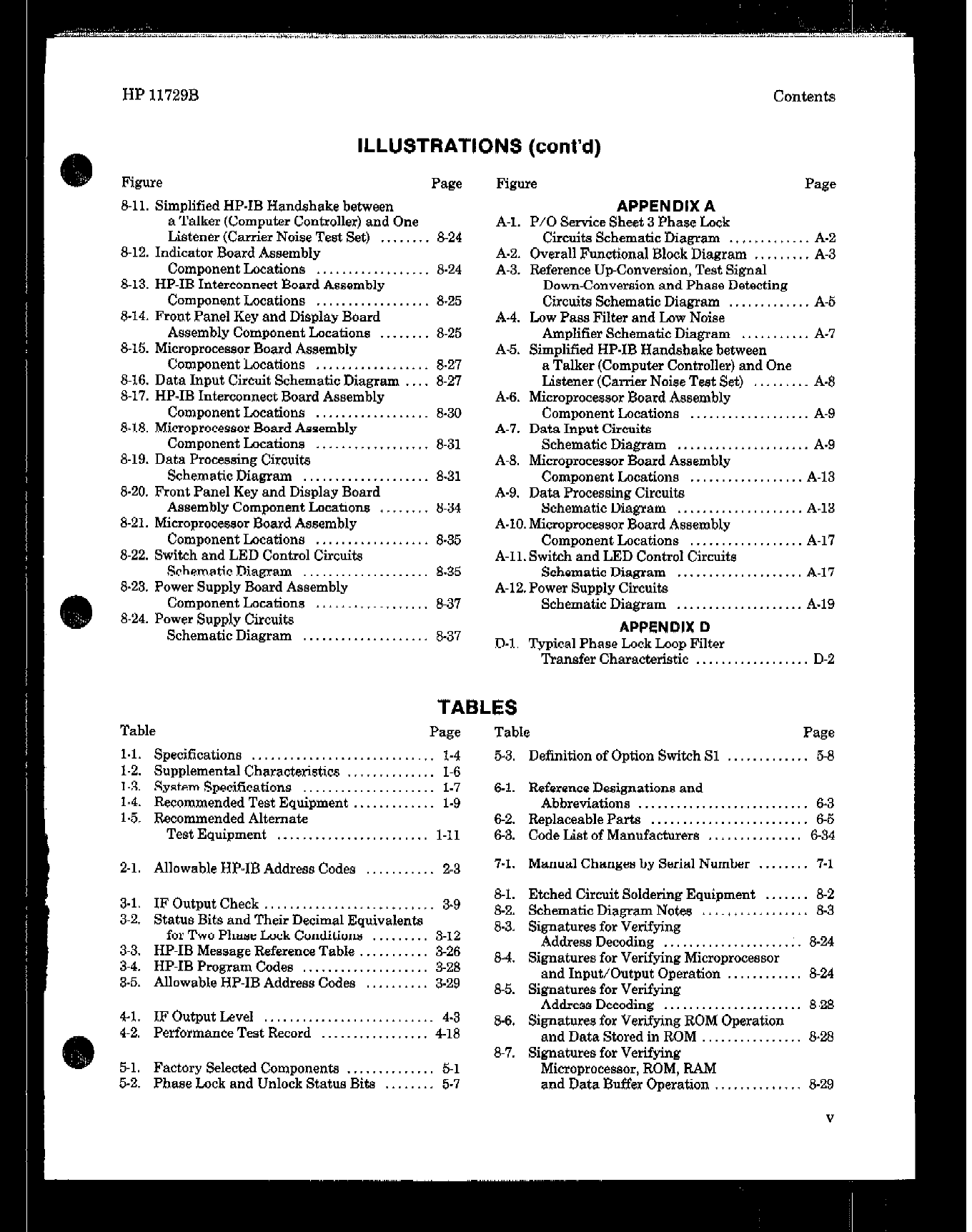

CONTENTS

Contents

Pam

Section I

GENERAL INFORMATION

Introduction .................................... l-l

Specifications ................................... 1-l

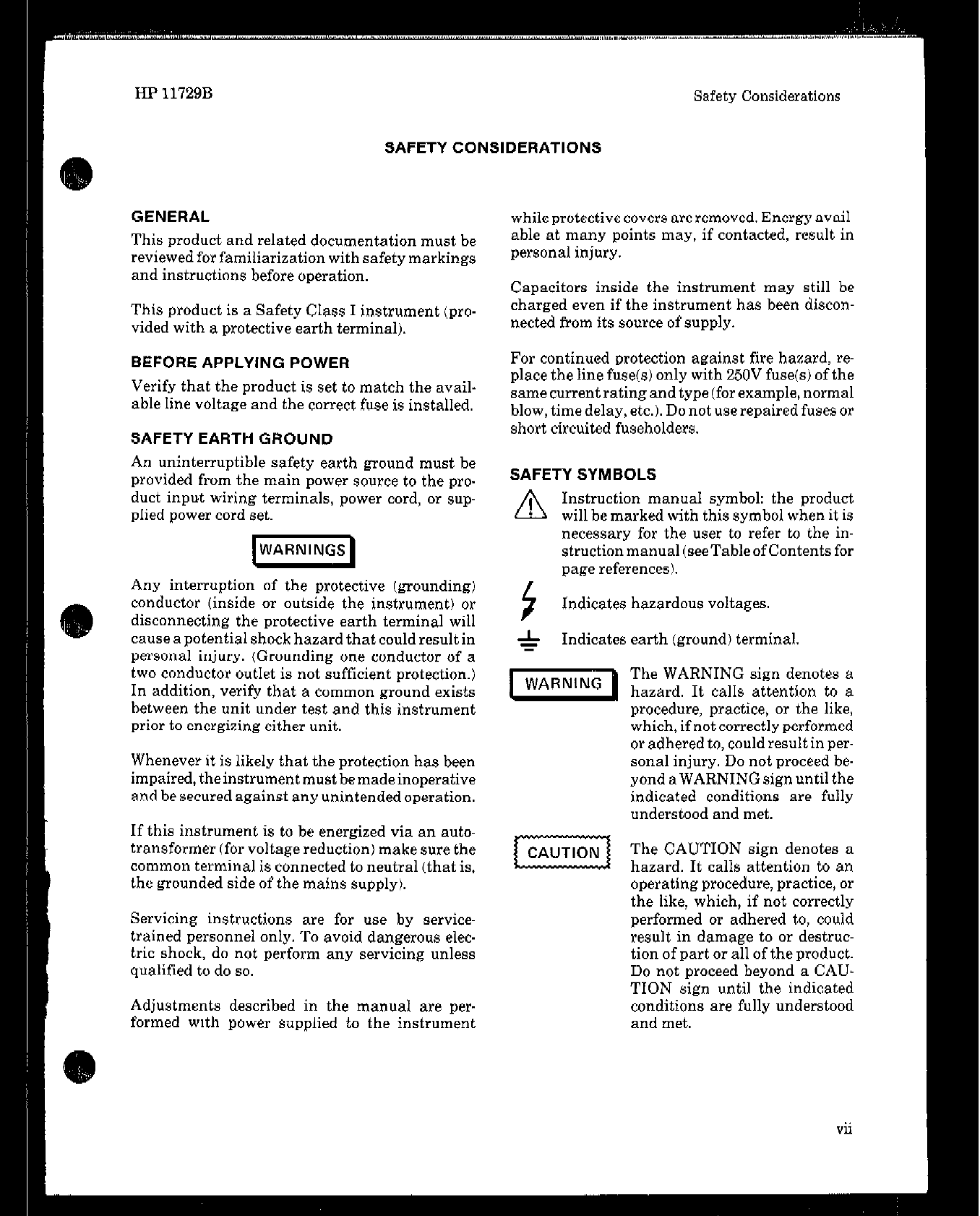

Safety Considerations ........................... 1.1

Instruments Covered by This Manual ........... 1.1

Manual Changes Supplement ................... I-1

Description ..................................... l-2

Options ......................................... 1.2

Electrical Options ............................. l-2

Mechanical Options ........................... 1-3

Accessories Supplied ............................ 1.3

Equipment Required But Not Supplied ........... l-3

Electrical Equipment Available ................. 1-3

Recommended Test Equipment .................. l-4

Section II

INSTALLATION

Introduction .................................... z-1

Initial Inspection ............................... 2-l

Preparation For Use ............................ 2-1

Power Requirements ..

A Line Voltage and Fuse Selection

....................................... 2-l

2-l

Power Cables ................................. 2-1

HP-IB Address Selection ...................... 2-2

Interconnections .............................. 2-3

Mating Connectors ........................... 2-3

Operating Environment ....................... 2.3

Bench Operation .............................. 2-5

Rack Mounting ............................... 2.6

Storage and Shipment .......................... 2-5

E

nvironment .................................

2-5

Packaging .................................... 2.5

Section Ill

OPERATION

Introduction 3-1

Local Operation 3.1

Remote Operation (HP-I@ t 3-l

Operator’s Checks t . 3-1

Operator’s Maintenance 3.1

Operator’s Checks . tt

3.1

General Operating Instructions 3-14

TurnOn . . . .. . . .. .. .. .. . . . . . . . . . . . . .. .. .. .. . .

3.14

Phase Noise Measurement 3.14

Phase Detector Method 3.14

Frequency Discriminator Method 3.22

AM Measurement (Option 130 only) 8-24

SectIon IV

PERFORMANCE TESTS

Introduction .................................... 4-1

Equipment Required ............................ 4-I

Teat Record ..................................... 4-1

Calibration Cycle ............................... 4.1

Page

Measurement Frequency Range,

IF Output Bandwidth and

Level Performance Tests 4-l

Residual Phase Noise Performance Test

(Using a test signal less than 1280 MHz) ....... 4-4

Residual Phase Noise Performance Test

(Using a test signal of 10 GHz) ................ 4-9

AM Noise Floor Performance Test .............. 4-14

Section

V

AOJUSTMENTS

Introduction .................................... 5-1

Safety Considerations ........................... 5.1

Equipment Required ............................ 5-I

Factory Selected Components ................... 6-1

Related Adjustments ............................ 5-l

Power Supply Adjuetment ....................... 5.2

Phase Lock Indicator Adjustment ............... 5-3

Option Switch Adjustment ...................... 5-8

Attenuator AT1 Selection ...................... 5.10

Section

VI

REPLACEABLE PARTS

Introduction .................................... 6-1

Abbreviations .................................. 6-l

Replaceable Parts Liat .......................... 6-l

Factory Selected Parts (*) ....................... 6-1

Parta List Backdating (-,) ........................ 6-1

Parts List Updating (Change Sheet) ............. 6-l

Illustrated Parts Breakdown ..................... 6-l

Hardware ...................................... 6.1

Ordering Information ........................... 6.1

Recommended Spares List ...................... 6-2

Sectlon VII

MANUAL CHANGES

Introduction .................................... 7-l

Manual Changes ............................... 7-l

Manual Change In&ructions .................... 7”l

Section VIII

SERVICE

Introduction .................................... S-l

Service Sheet e .................................. 8-l

Block D’lagTam% .............................. 8-l

Schematics ................................... 8-l

Safety Considerations ........................... 8-l

Before Applying Power ........................ 8-l

safety ........................................ 8-l

Recommended Test Equipment .................. 8-l

Service Tools, Aids and Information ............. 8-l

Pozidriv Screwdrivers ......................... 8-l

TuningTools .................................

8.2

Heat Staking Tools ........................... 8-2

Hardware .................................... 8-2

Ma.intenance .................................

8-2