7

Introduction

Designed for applications requiring multi-purpose loading systems, such

as road construction projects in either mobile or fixed labs, educational

institutions and consulting firms, the HM-5030 Master Loader is ideal for

just about any application from road construction to high-volume com-

mercial and educational laboratories.

While the HM-5030 has been specifically designed for soil testing labs

conducting multiple testing operations including: UU, CU and CD tri-

axial, UC, CBR and LBR, it is also perfect for running Marshall, Hveem,

TSR and SCB asphalt tests as well. Its heavy-duty design and precise

stepper-motor control provide a stable platform for years of reliable ser-

vice allowing the HM-5030 to perform any tests required up to its load

capacity of 11000 lbf (50kN).

Like all elite series load frames, the HM-5030 is built around Humboldt's

integral, 4-channel data logger with touch-screen control, which allows

the load frame to be used as a standalone device capable of full test

control and data logging. It can also be controlled by a networked com-

puter at any location with access to the network.

The HM-5030 provides four (4) integral and independent data acquisi-

tion channels, which can be utilized in stand-alone configurations or

accessed through a LAN-networked computer using Humboldt's Next

Software.The HM-5030 load frame is built with durable, high-quality

components and features the use of a stepper motor, precision gears

and gear box to ensure smooth and reliable operation, as well as precise

results.

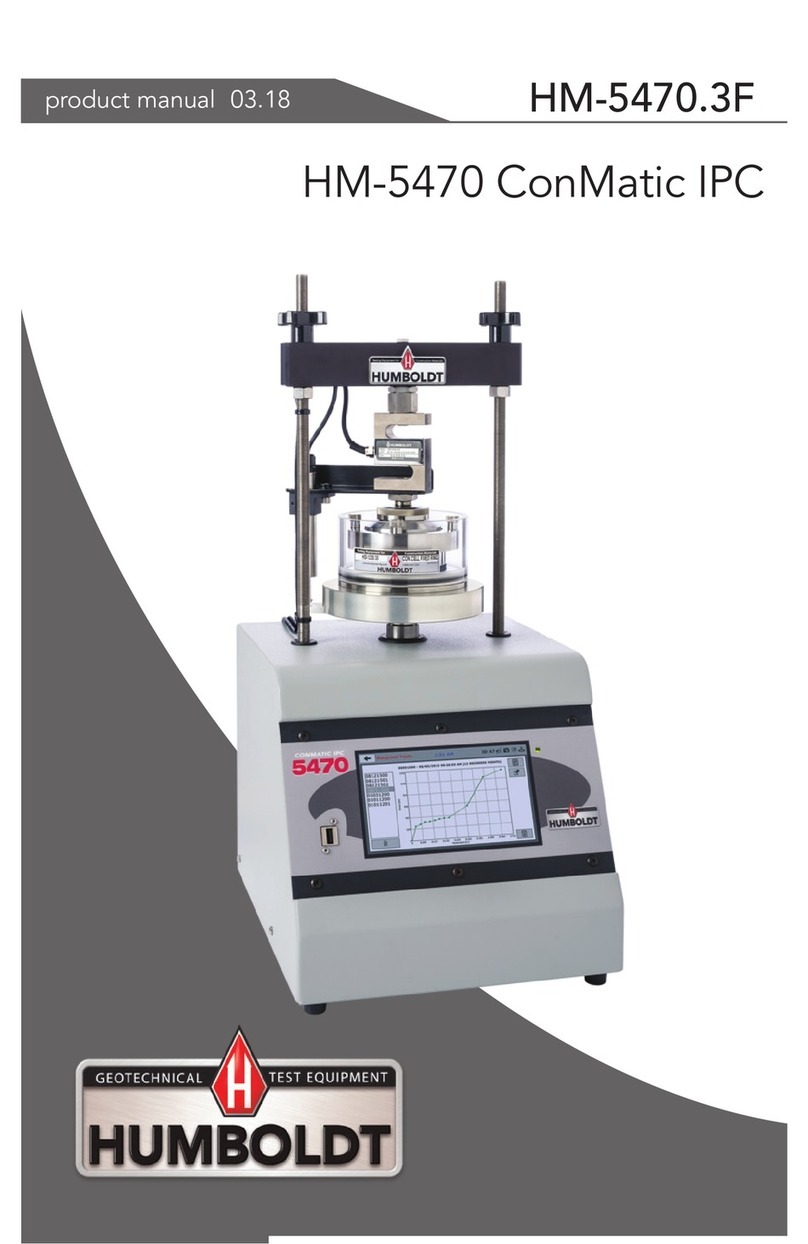

In stand-alone mode, the HM-5030 load frame provides a 7" (178mm)

touch-screen controller, giving you finger-tip control of your testing pro-

cesses, as well as providing real-time, visual views of your data in both

tabular and graphic formats. This waterproof, touch screen provides

colorful, at-a-glance monitoring of testing functions without the use

of a computer. Operators can see all the data in several formats at the

machine while the test is running. Data can then be viewed simultane-

ously or downloaded later to a computer in the lab, in the next room or

at a different location, while also providing report generation capabilities

from within Humboldt's NEXT software or our enhanced test-specific

modules.

Touch-Screen Controller provides:

• 4-channel data acquisition

• Hi-res, 7", waterproof, touch-screen provides total control and real-

time graphical display of tests

• Machine /Test control and data acquisition via touch-screen