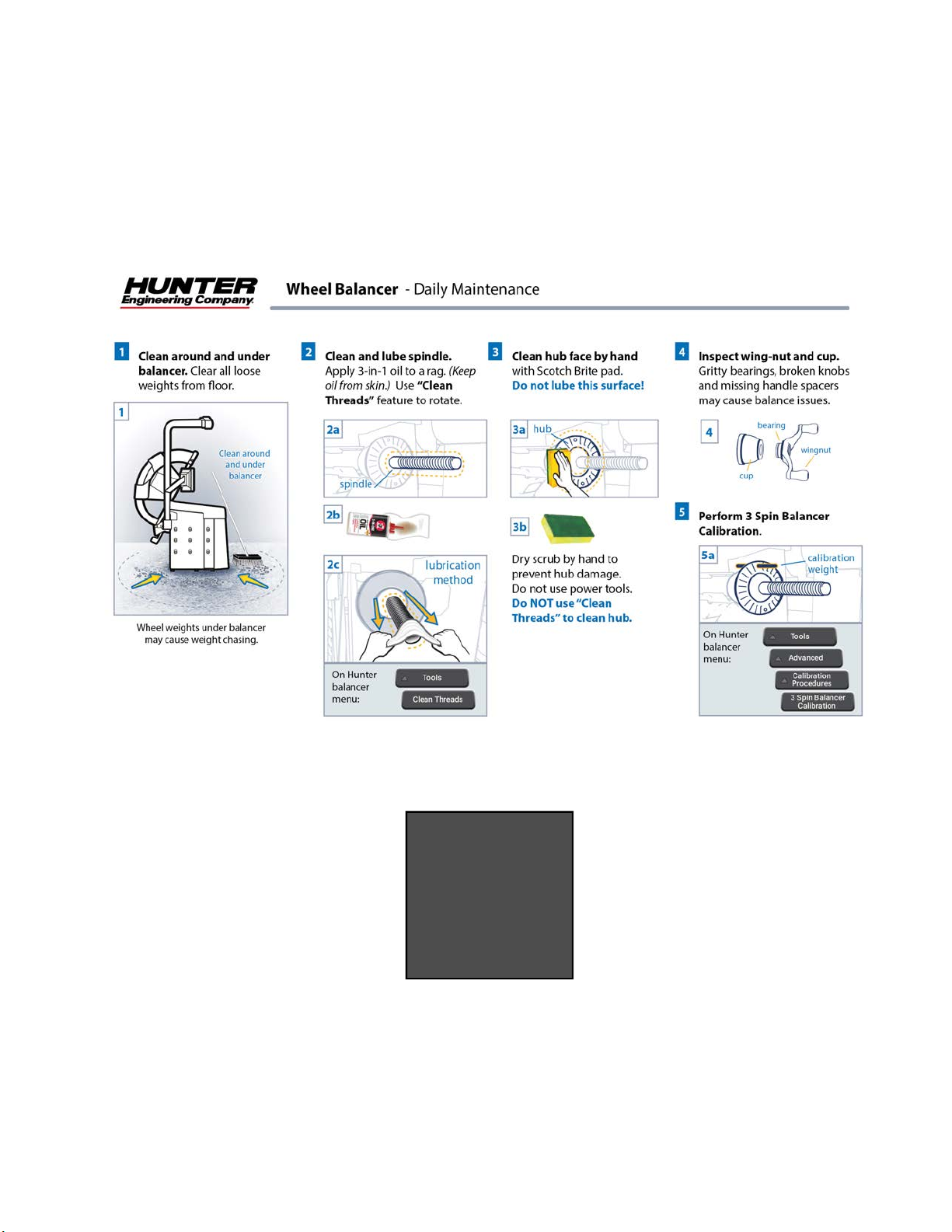

Getting Started 5

1. Getting Started

1.1 Introduction

Read this manual prior to operating. Equipment owner is

responsible for training. Equipment is meant to be use by

trained operator and this manual assumes the technician

has been trained.

Corporate Information

• Hunter Engineering Company: 11250 Hunter Drive

Bridgeton, MO 63044 U.S.A.

• Phone: 314-731-3020 / Fax: 314-731-1776

Web: www.hunter.com

1.2 For Your Safety

Hazard Definitions:

These symbols identify situations that could be detrimen-

tal to your safety and/or cause equipment damage.

Important Safety Instructions - Electrical

• Do not operate equipment with a damaged cord or

damaged until examined by a Hunter Service Repre-

sentative.

• An extension cord must use current rating equal to or

better than that of the equipment.

• Never use cord to pull plug from the outlet.

• Balancer requires a properly grounded electrical sup-

ply.

• Verify electrical supply circuit match’s balancer volt-

age and amperage ratings.

• Do not alter electrical plug.

• Don’t plug into unsuitable supply circuit as equipment

damage or injury may result.

• Ensure power switch is in the off position("O" posi-

tion) before plugging equipment into electrical outlet.

Important Safety Instructions - Operation

• Do not operate equipment near open containers of

flammable liquids (gasoline).

• Read and follow all caution and warning labels

affixed to your equipment and tools. Misuse of this

equipment can cause personal injury and shorten the

life of the balancer.

• Keep all instructions permanently with the unit.

• Keep all decals, labels, and notices clean and visible.

• To prevent accidents and/or damage to the balancer,

use only Hunter recommended accessories.

• Use equipment only as described in this manual.

• Never stand on the balancer.

• Wear non-slip safety footwear when operating the

balancer.

• Keep hair, loose clothing, neckties, jewelry, fingers,

and all parts of body away from all moving parts.

• Do not use on wet surfaces or expose to rain.

• Wear OSHA approved safety glasses.

Important Safety Instructions - Balancers

• Keep the safety hood and its safety interlock system

in good working order.

• Do not place any tools, weights, or other objects on

the safety hood while operating the balancer.

• Verify wheel is mounted properly and wing nut is

firmly tightened before operation.

• The safety hood must be closed before touching the

green “START” button, to spin the wheel.

• Hood Autostart will cause the balancer shaft to spin

automatically upon hood closure. .

• Raise safety hood only after wheel has come to a

complete stop.

• The red “STOP” button, can be used for emergency

stops.

• Never reach under the hood while wheel is in motion.

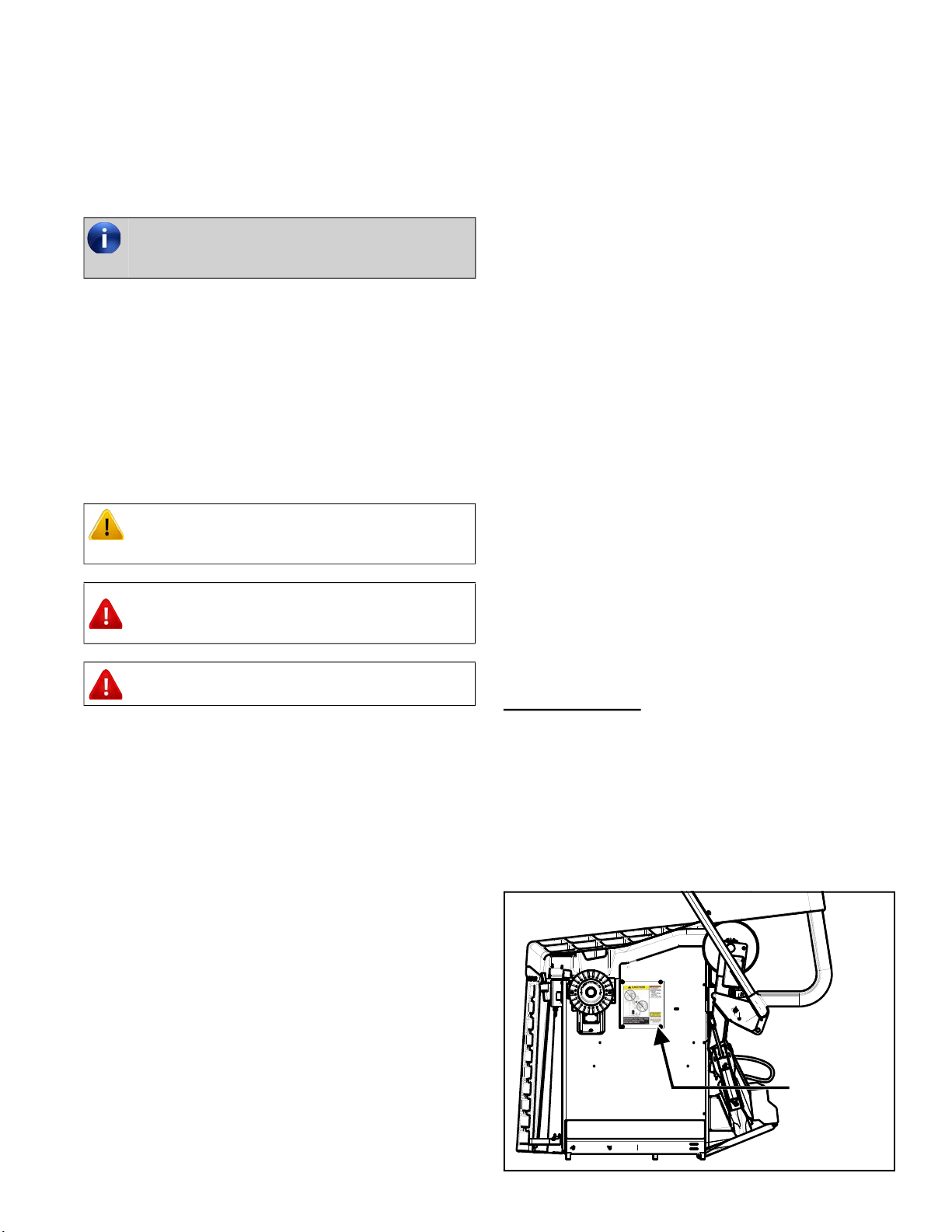

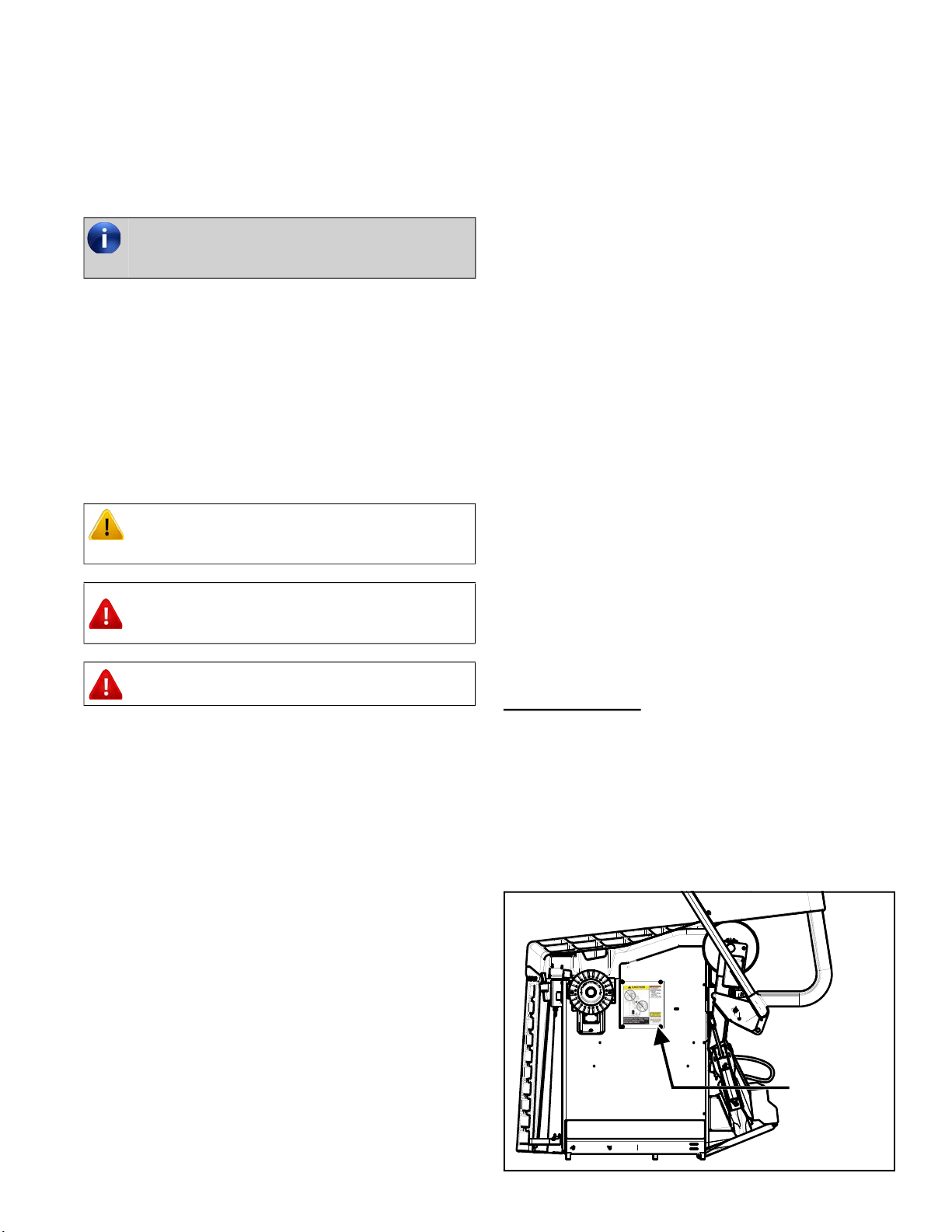

1.3 Decal Information & Placement

Right Side View.

• Decal 128-1244-2 cautions that spindle rotation may

occur with foot pedal depression and to keep clear of

clamping components during shaft rotation.

• Decal 128-964-2 gives the maximum wheel diameter

and maximum wheel weight for balancer

• EN/IEC Class 1 Laser Product Certification is shown

on Decal 128-1638-2.

• An explanation of FDA compliance standards is

shown on Decal 128-1117-2.

Installation of balancer should be completed

only by an authorized Hunter Service

Representative.

CAUTION: Hazards or unsafe practices,

which could result in minor personal injury or

product or property damage.

WARNING: Hazards or unsafe practices,

which could result in severe personal injury

or death.

DANGER: Immediate hazards, which will

result in severe personal injury or death.

128-1244-2

128-1638-2

128-964-2

128-1117-2