To reduce the risk of electrical shock, do not use on wet surfaces or expose to rain.

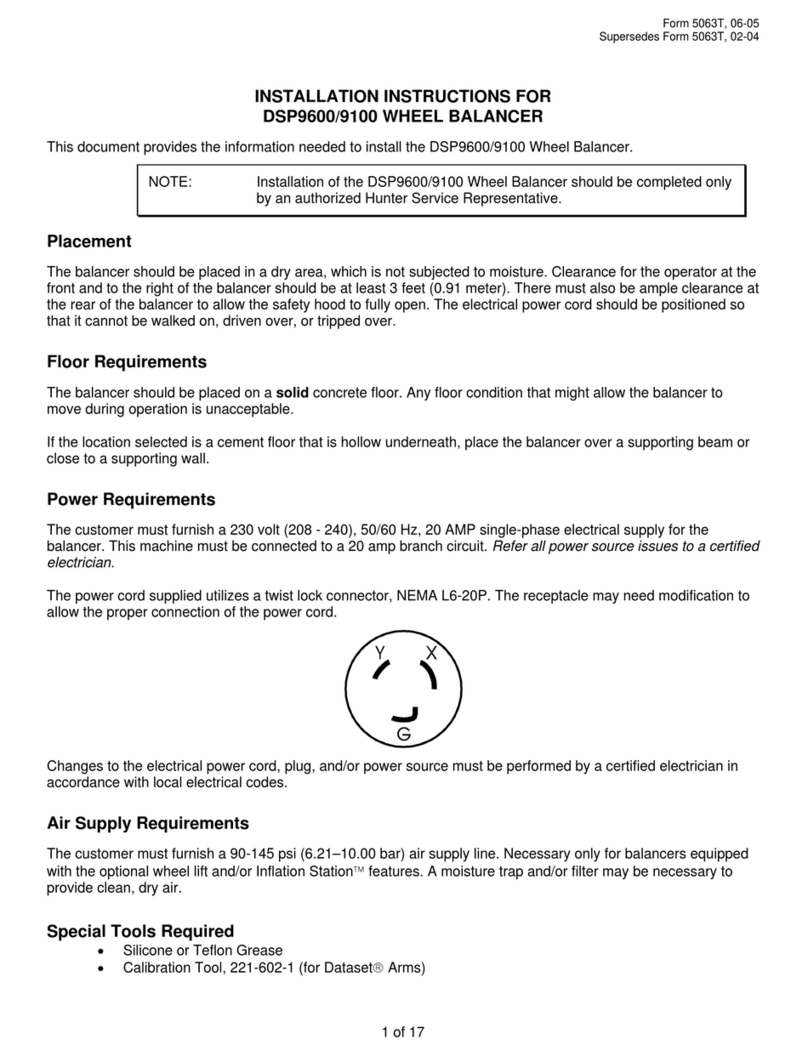

Verify the appropriate electrical supply circuit is the same voltage and amperage rangs as marked on the equipment

before operang.

WARNING

DO NOT ALTER THE ELECTRICAL PLUG. Plugging the electrical plug into an unsuitable supply circuit will

damage the equipment and may result in personal injury.

When servicing the SmartWeight® Pro, power must be disconnected by removing the power cord from the electrical

outlet. Ensure that the SmartWeight® Pro power switch is in the o posion ("O" posion) before plugging the power cord

into the electrical power outlet.

2.2.3. Important Safety Instructions - Operation

To reduce the risk of re, do not operate equipment near open containers of ammable liquids (gasoline). Read and follow

all cauon and warning labels axed to your equipment and tools. Misuse of this equipment can cause personal injury

and shorten the life of the equipment. Keep all instrucons permanently with the unit. Keep all decals, labels, and noces

clean and visible. To prevent accidents and/or damage to the Balancerrecommended accessories. Use equipment only as

described in this manual. Never stand on the Balancer. Wear non-slip safety footwear when operang the Balancer. Keep

hair, loose clothing, neckes, jewelry, ngers, and all parts of body away from all moving parts. ALWAYS WEAR OSHA

APPROVED SAFETY GLASSES. Eyeglasses that have only impact resistant lenses are NOT safety glasses.

2.2.4. Important Safety Instruction - Balancers

Keep the safety hood and its safety interlock system in good working order.

Do not place any tools, weights, or other objects on the safety hood while operang the balancer.

Verify that the wheel is mounted properly and that the wing nut is rmly ghtened before spinning the wheel.

The safety hood must be closed before touching the green “START” buon, to spin the wheel.

Raise safety hood only aer wheel has come to a complete stop. If safety hood is raised before the spin is com-pleted, the

weight values will not be displayed.

The red “STOP” buon, can be used for emergency stops.

2.2.5. Decal Information & Placement - SWP

• Decal 128-1244-2 cauons the operator that spindle rotaon may occur with foot pedal depression and to keep clear of

clamping components during sha rotaon.

• Decal gives the maximum wheel diameter and maximum wheel weight for the SW Pro.

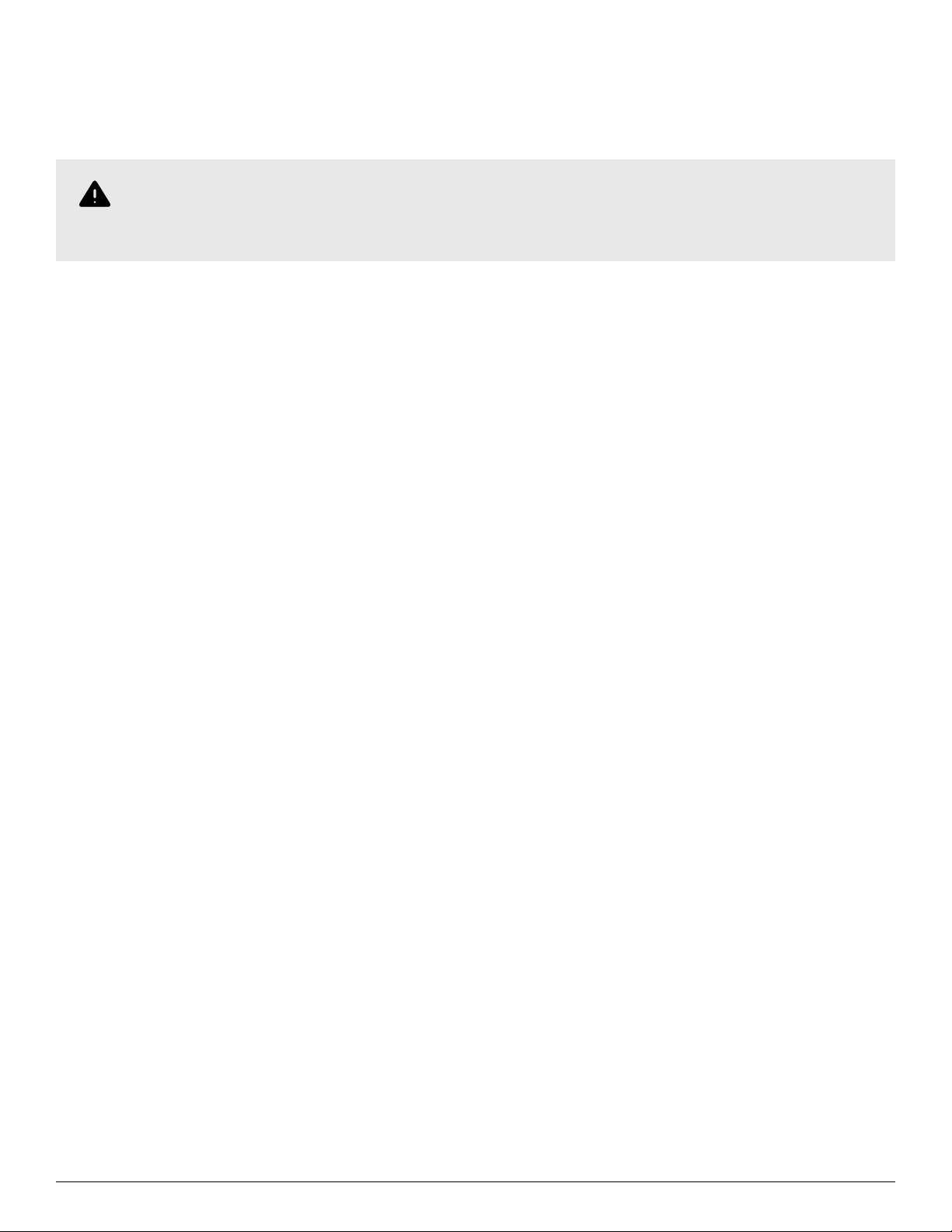

• EN/IEC Class 3R Laser Product Cercaon is shown on Decal 128-2016-2-08. This label shows the EN/IEC standards

for a Class 3R Laser Product.

• An explanaon of FDA compliance standards is shown on Decal 128-2016-2-08. FDA performance standards compli-

ance is shown on the decal.

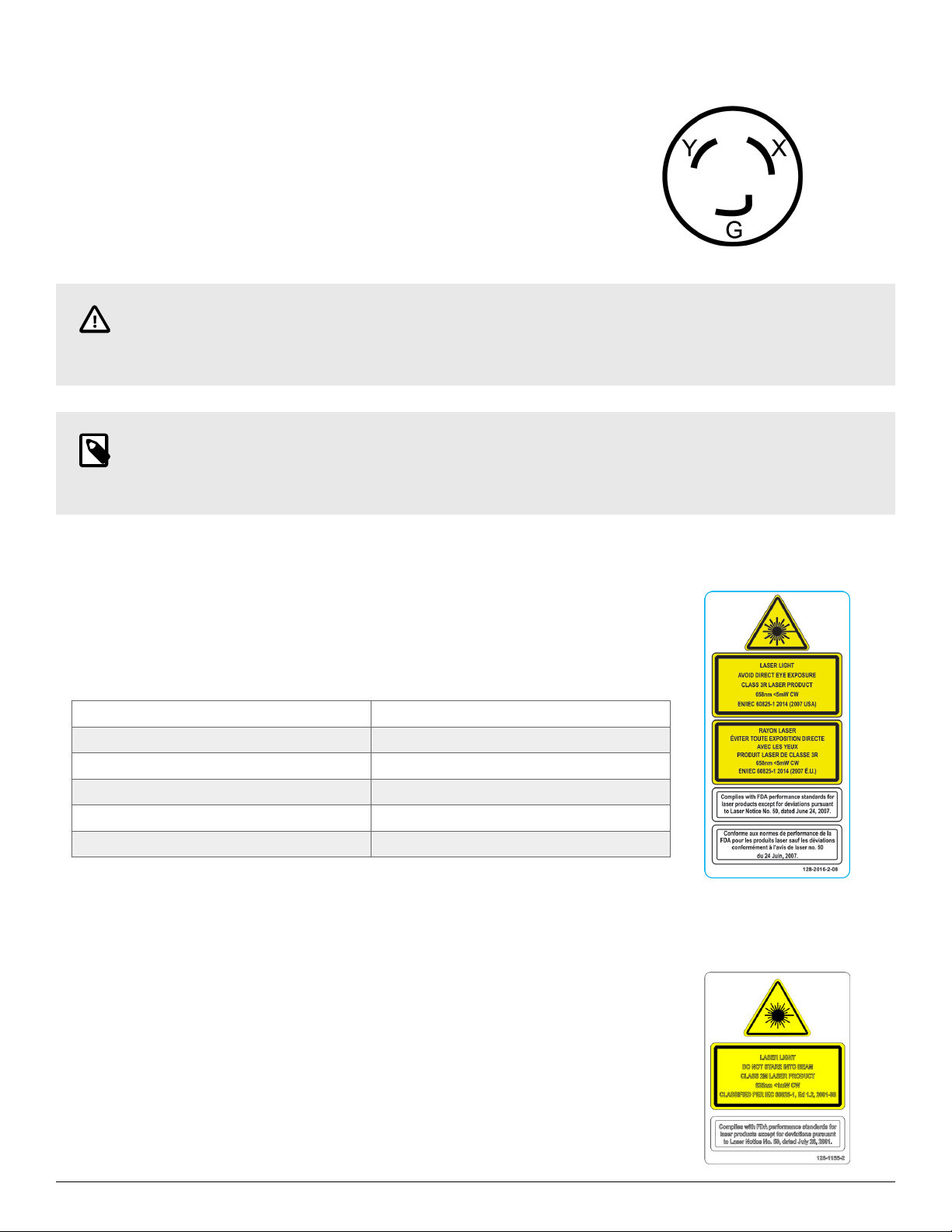

• For units with TDC Laser, FDA standards for Class 2M laser compliance are shown on Decal 128-1155-2.

• Decal 128-381-2 warns the operator not to remove the covered of the SW Pro because of the risk of the electrical shock

and not to use below garage oor level.

• ETL cercaon standards are outlined on Decal 128-1120-2. Users are cauoned not to use the balancer below garage

level.

• A manufacturer's idencaon is also on the rear of the balancer.

SmartWeight® Pro Operations Manual

Page 5 of 11