MSCON

First Step Guide First Edition

Thank you for purchasing our product.

Make sure to read the Safety Guide and detailed Instruction Manual (CD/DVD) included with the product in addition to

this First Step Guide to ensure correct use.

This Instruction Manual is original.

•Using or copying all or part of this Instruction Manual without permission is prohibited.

•The company names, names of products and trademarks of each company shown in the sentences are registered

trademarks.

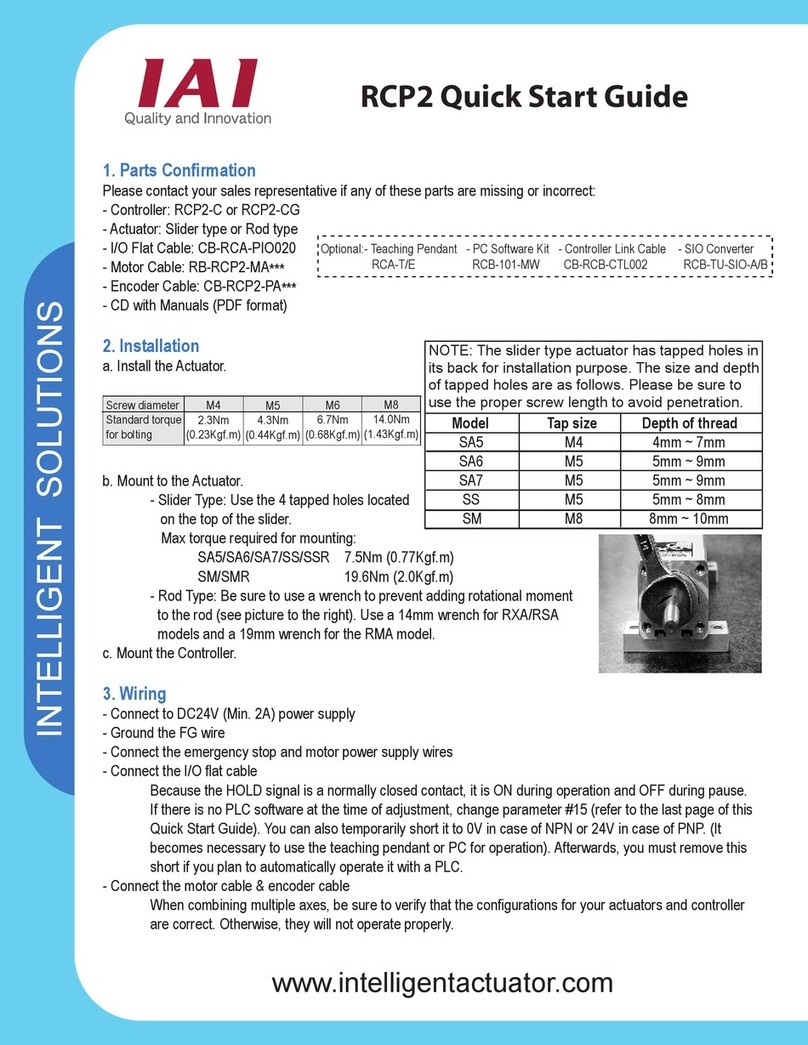

Product Check

This product is comprised of the following parts if it is of standard configuration.

If you find any fault in the contained model or any missing parts, contact us or our distributor.

1. Parts

No. Part Name Model Quantity Remarks

1 Controller Refer to “How to read the model

plate”, “How to read the model” 1

Accessories

2 Control Power Supply

Connector

MC1.5/5-STF-3.81

(Supplier: PHOENIX CONTACT) 1

Recommended cable size

•

Control Power Input area

KIV3.5 to 0.75mm2

(AWG12 to 18)

•Brake Power Input area

KIV0.75mm2

(AWG18)

3 Motor Power Supply

Connector

GMSTB2.5/3-STF-7.62

(Supplier: PHOENIX CONTACT) 1

Recommended cable size

KIV3.5 to 1.25mm2

(AWG12 to 16)

4 System I/O Connector FMCD1.5/4-ST-3.5

(Supplier: PHOENIX CONTACT) 1

Recommended cable size

KIV1.25 to 0.2mm2

(AWG16 to 24)

5 CC-Link Connector

(For CC-Link Type)

SMSTB2.5/5-ST-5.08 AU

(Supplier: PHOENIX CONTACT) 1

Trminal resistance

(130Ω1/2W, 110Ω1/2W)

enclosed one unit each

6 DeviceNet Connector

(For DeviceNet Type)

SMSTB2.5/5-ST-5.08 AU

(Supplier: PHOENIX CONTACT) 1

Prepare a terminal resistor

separately if this controller is

to be allocated at the

terminal.

7 Absolute Battery Unit

(Option) (Battery AB-5) -

Depends on number of

actuators to be used in

absolute type

8 First Step Guide 1

9 Instruction Manual

(CD/DVD) 1

10 Safety Guide 1

2. Teaching Tool (to be purchased separately)

For the setup operation such as position setting and parameter setting by a teaching, conduct it on PC software.

Prepare a teaching tool such as PC software and so on for the operations and tunings.

No. Part Name Model

1 PC Software

(Includes RS232C Exchange Adapter + Peripheral Communication Cable) RCM-101-MW

2

PC Software

(Includes USB Exchange Adapter + USB Cable + Peripheral Communication

Cable)

RCM-101-USB

3 Teaching Pendant (Touch panel teaching) CON-PTA

4 Teaching Pendant (Touch panel teaching equipped with a deadman switch) CON-PDA

5

Teaching Pendant

(Touch panel teaching equipped with a deadman switch + TP adapter

(RCB-LB-TG))

CON-PGA

6 Teaching Pendant CON-T

7 Teaching Pendant (equipped with dead man’s switch + TP adapter (RCB-LB-TG)) CON-TG

8 Gateway Parameter Setting Tool -

3. Instruction Manuals related to this product, which are contained in the Instruction Manual (CD/DVD).

No. Name Manual No.

1 MSCON Controller Instruction Manual ME0304

2 PC Software RCM-101-MW/RCM-101-USB Instruction Manual ME0155

3 Touch Panel Teaching CON-PTA/PDA/PGA Instruction Manual ME0295

4 Teaching Pendant CON-T/TG Instruction Manual ME0178

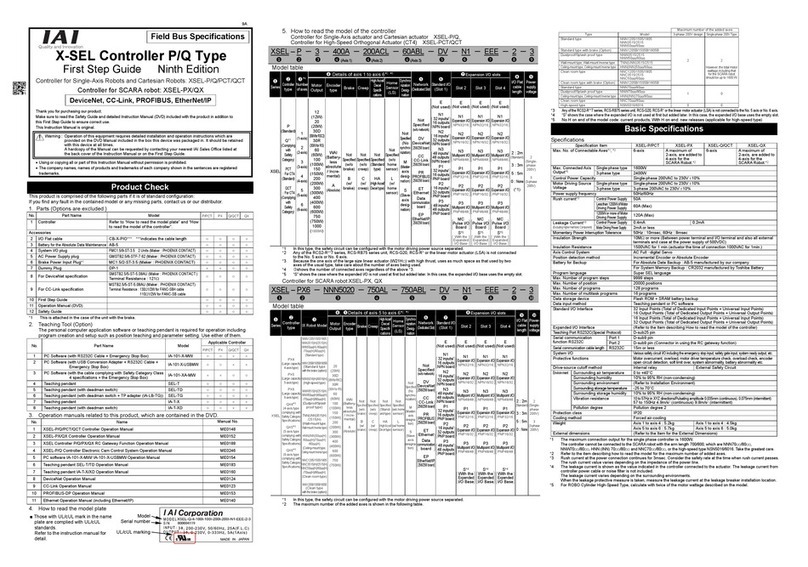

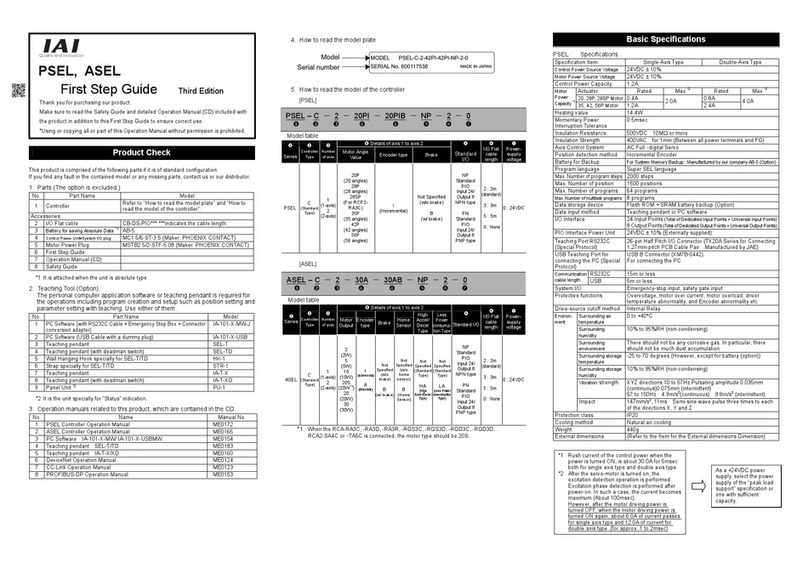

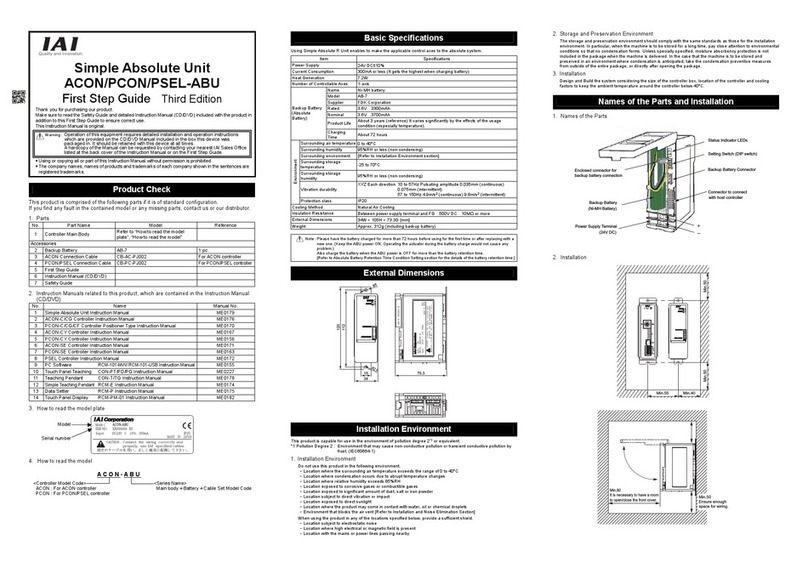

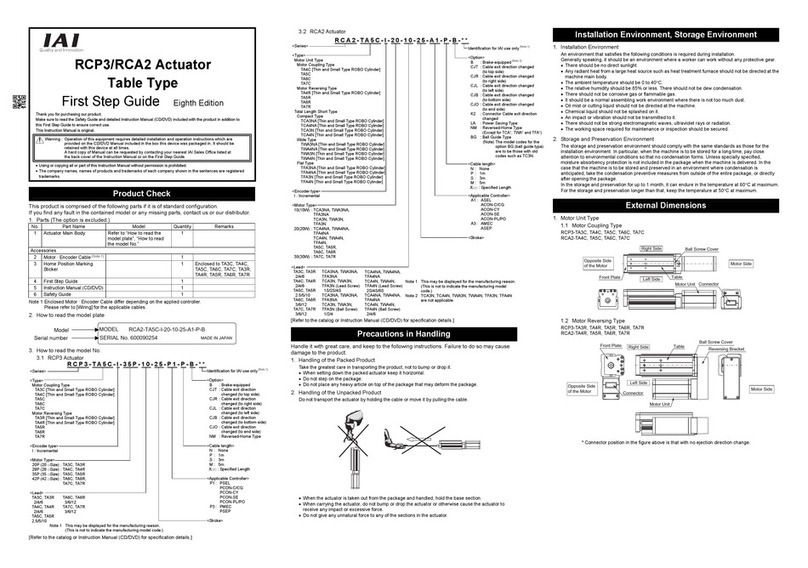

4. How to read the model plate

5. How to read the model

(Example) Consists of 5 axes : Axis No.0, 2, 3 = 60W actuators to be connected incremental type

Axis No.4, 5 = 100W actuators to be connected incremental type

Axis No.1 = When no connected axis

MSCON-C-5-60I-N-60I-60I-100I-100I-DV-2-0-**

Basic Specifications

Specifications

Number of Controlled Axes Max. 6-axis

Control Power Voltage 24V DC ± 10%

Control Power Current

Consumption Max. 2.4A

Add the Control Power In Rush

Current (Note1) Max. 7A 5msec or less

Driving Source

Voltage

100V AC

Specification

AC100 to 115V ± 10%

Drive (Motor)

Power Supply

Voltage Driving Source

Voltage

200V AC

Specification

AC200 to 230V ± 10%

Driving Source

Voltage

100V AC

Specification

10A max. with 20A for 80msec (driving source voltage 100V in ambient temp. 25°C)

10A max. with 45A for 80msec (driving source voltage 115V × 10% in ambient temp. 40°C)

Drive (Motor)

Power Supply

In-Rush

Current (Note1) Driving Source

Voltage

200V AC

Specification

10A max. with 45A for 40msec (driving source voltage 200V in ambient temp. 25°C)

10A max. with 95A for 40msec (driving source voltage 230V × 10% in ambient temp. 40°C)

Driving Source

Voltage

100V AC

Specification

Max. 200W/axis (up to 450W in total for six axes)

Motor

Capacity of

Connectable

Actuators Driving Source

Voltage

200V AC

Specification

Max. 200W/axis (up to 900W in total for six axes)

Electromagnetic Brake Power

Supply Voltage

(when brake-equipped actuator

connected)

DC24V ± 10%

Brake Power Supply Current Max. 1A/axis (0.5A/axis at steady state)

Brake Power Supply In-Rush

Current (Note1) Max. 10A 10msec or less

Drive (Motor) Power Capacity Refer to Power Capacity and Heat Generation.

Leak Current 3.5mA (Motor power supply)

◎There is no leak current of control power supply and brake power supply.

Heat Generation Refer to Power Capacity and Heat Generation.

Drive (Motor) Frequency 50/60Hz ± 5%

Transient Power Cutoff Durability 1msec (Control Power Supply), 20msec (Drive (Motor) Power Supply), 5msec (Brake

Power Supply)

Motor Control System Sinusoidal Wave PWM Vector Current Control

Applicable Encoder Incremental Serial Encoder

Absolute Serial Encoder

Actuator Cable Length Max. 20m

Serial Communication

(SIO Port: For Teaching) RS485 1ch (complying with Modbus Protocol) Speed : 9.6 to 230.4kbps

External Interface DeviceNet, CC-Link, PROFIBUS-DP, CompoNet, MECHATROLINK ll, EtherNet/IP,

EtherCAT®

Data Setting and Input PC software, Teaching pendant, Gateway parameter setting tool

Number of Positioning Points Position data and parameters are saved in the nonvolatile memory.

(There is no limitation in number of writing)

Number of Positioning Points Max. 256 points (There is no limit for simple direct and direct indication modes)

Note: The number of positioning points differs depending on the operation mode select

by the parameter setting.

LED Indication

(Mounted on Front Panel)

LED lamp for driver status display 2 points

Gateway Status LED 5 points

Fieldbus Status LED 2 points

Power Supply Status LED 2 points

Forcibly Releasing of

Electromagnetic Brake

(Mounted on Front Panel) Switching NOM (standard)/RLS (compulsory release)

Protective Functions Overload, overcurrent, overvoltage, etc.

Protection Function against

Electric Shock Class I

Insulation Resistance (Between

secondary power source and FG) 500V DC 10MΩor more

Withstanding Voltage (Between

primary and secondary power

sources, Between primary power

source and PE)

1500V AC for 1 min. (for MSCON individually)

Cooling Method Forced air-cooling

External Dimensions 225W × 154H × 115D

Incremental Type Approx. 1900g

Weight

(when drivers

for 6 axes

mounted) Absolute Type Approx. 2000g (including batteries)

Surrounding air

temperature 0 to 40°C

Surrounding humidity 85%RH or less (non-condensing)

Surrounding environment

[Refer to Installation and Storage Environment.]

Surrounding storage

temperature -20 to 70 °C

(Note) 0 to 40 °C for absolute battery.

Surrounding storage

humidity 85%RH or less (non-condensing)

Usable Altitude 1000m or lower above sea level

Vibration Durability Frequency 10 to 57Hz/ Swing width: 0.075mm

Frequency 57 to 150Hz/ Acceleration 9.8m/s2

XYZ Each direction Sweep time: 10 min. Number of sweep: 10 times

Package Drop Dropping height 800mm, 1 corner, 3 edges and 6 surfaces

Protection Class IP20

Pollution Degree I

Enviro-

nment

Overvoltage Category II

Note 1 The rush current value varies depending on the impedance of the power line.

<Power Capacity and Heat Generation>

Shown in the table is the relation between the motor wattage and motor power capacity of an actuator that

can be connected

RS : Rotary Shaft

<Remark 1> Selection of Circuit Breaker

•3 times of the rated current flows to the controller during the acceleration/deceleration. Select an

interrupter that does not trip with this value of current. If a trip occurs, select an interrupter that

possesses the rated current of one grade higher. (Check the operation characteristics curves in the

product catalog.)

•Select an interrupter that does not trip with the in-rush current. (Check the operation characteristics

curves in the product catalog.)

•Consider the current that enables to cutoff the current even when a short circuit current is flown for

the rated cutoff current.

Rated Interrupting Current > Short Circuit Current = Circuit Breaker Primary Power Capacity / Power Voltage

Consider margin for the rated current on the circuit breaker.

<Remark 2> Selection of Leak Current Breaker

•It may be mandatory by low to install a leakage breaker.

•A ground fault circuit interrupter needs to be selected carefully considering the purposes of prevention

of fire and protection of human (Determined by law).

•Leak current varies depending on the capacity of connected motor, cable length and the surrounding

environment. Measure the leak current at the point where a ground fault circuit interrupter is to be

installed when leakage protection is conducted.

•Use the harmonic type (for inverter) for the ground fault circuit interrupter.

<Control Power Capacity>

Follow the description below for the calculation of 24V DC power capacity.

(1) Control Power Current Consumption :

Select from control power supply current in the table below ··············1)

Number of Controlled Axes (Note1) 1 Axis 2 Axis 3 Axis 4 Axis 5 Axis 6 Axis

Control Power Unit Heating Value [W] 25.5 31.5 38.2 44.2 50.9 56.9

Control Power Capacity [A] 1.1 1.3 1.6 1.8 2.1 2.4

Note 1 : See the line of max. number of controlled axes connectable to corresponding MSCON.

manufacturing name plate : MSCON-C-*-• • • •: “*” is the maximum number of connectable axes.

(2) Current Consumption of Brake Power Supply :

1A or 0.5A (Note 2) × number of brake-equipped actuators ··············2)

Note 2 : The maximum current of 1A per actuator runs for approximately 100ms when a brake is

released. The current consumption after the release is 0.5A per unit.

Calculate the capacity with 0.5A per unit when a 24V DC power supply corresponding to

transient load change such as peak load appliance is used and capable for the maximum

current described above. For other cases, calculate with 1A per unit.

(3) Add the Control Power In Rush Current : 7A ····································································3)

[Selection of Power Supply]

Usually, the rated current is to be approximately 1.3 times higher than the total of Control Power 1) and

Motor Power 2) above considering approximately 30% of margin to the load current. However, considering

the inrush currents [excitation 3)], even though it is a short time, select a power supply with sufficient “peak

load capacity”. If a power supply with insufficient peak capacity is utilized, a transient voltage drop or cutoff

may occur. This may present issues with power supplies providing remote sensing functionality.

<Remark 3> Selection of Power Supply Protection Circuit Breaker

It is recommended that the power supply protection is conducted on the primary side (AC power side)

of the 24V DC power supply unit.

If having 24V DC turned ON/OFF, keep the 0V connected and have the +24V ON/OFF (cut one side only).

Be careful to the in-rush current of the 24V DC power supply unit when making a selection. (Check it in

the operation characteristics curve graph in a catalog provided by the supplier.)

Consider the current that enables to cutoff the current even when a short circuit current is flown for the

rated cutoff current.

•

Rated Interrupting Current > Short Circuit Current = Circuit Breaker Primary Power Capacity / Power Voltage

•(Remark) In-rush Current of IAI Power Supply Unit PS241 = 50 to 60A, 3msec

Actuator Motor Wattage Motor Power Capacity [VA] Peek Max. Motor Power Capacity [VA] Heat Generation [W]

12 41 123 1.7

20 50 150 2.0

30D (Excluding RS) 47 141 2.0

30R (for RS) 138 414 4.0

60 146 438 4.8

100 238 714 7.0

150 328 984 8.3

200 421 1263 9.2

<Type Name>

C : Standard Type

<Connected Axis>

1 to 6 : Number of driver axes

<Detail of Connected Axis>

[Motor Type]

12 : 12W Servo Motor, 20 : 20W Servo Motor

30D : 30W Servo Motor, 30R : 30W Servo Motor (for RS Series)

60 : 60W Servo Motor, 100 : 100W Servo Motor

150 : 150W Servo Motor, 200 : 200W Servo Motor

N : Not connected

[Encoder Type]

I : Incremental

A : Absolute

[Option]

HA : High Accel/Decel Type

L : Home Sensor/Limit Switch Type

C : Creep Sensor Type

B : Brake Type

<Identification for IAI use only>

*There is no identification in

some cases

<Power-supply Voltage>

1 : AC100V

2 : AC200V

<I/O cable Length>

0 : No cable

<I/O Type>

DV : DeviceNet Type

CC : CC-Link Type

PR : PROFIBUS-DP Type

CN : CompoNet Type

ML : MECHATROLINK Type

EP : EtherNet/IP Type

EC : EtherCAT® Type

Applicable Field Network

(DeviceNet, CC-Link, PROFIBUS, CompoNet,

MECHATROLINK-ll, EtherNet/IP, EtherCAT®)

Rated Current for Circuit Interrupter >

Total capacity of motor power for all the connected actuators / AC input voltage × Safety margin (1.2 to 1.3 for reference)

MODEL MSCON-C-6-200AHA-200AHA-200AB-100A-100A-60AB-DV-0-2

SERIAL No.01234567

Model No.

Serial number

Warning : Operation of this equipment requires detailed installation and operation instructions which are

provided on the CD/DVD Manual included in the box this device was packaged in. It should be

retained with this device at all times.

A hard copy of Manual can be requested by contacting your nearest IAI Sales Office listed at

the back cove

of the Instruction Manual or on the First Step Guide.