RCP4 Actuator

Gripper Type

First Step Guide Second Edition

Thank you for purchasing our product.

Make sure to read the Safety Guide and detailed Instruction Manual (CD/DVD) included with the product in addition to

this First Step Guide to ensure correct use.

This Instruction Manual is original.

• Using or copying all or part of this Instruction Manual without permission is prohibited.

• The company names, names of products and trademarks of each company shown in the sentences are registered

trademarks.

This product is comprised of the following parts if it is of standard configuration.

If you find any fault in the contained model or any missing parts, contact us or our distributor.

1. Parts (The option is excluded.)

No. Part Name Model Quantity Remarks

1

Actuator

Refer to “How to Read the Model

Nameplate” and “How to Read the Model

Number.”

1

Accessories

2 Motor • encoder

cables (Note1)

1

3 First Step Guide 1

4 Instruction Manual

(DVD)

1

5 Safety Guide 1

Note 1 Please refer to the wiring layout for the enclosed motor cable and encoder cable.

2. How to read the model plate

3. How to read the model No.

Note 1 Identification for IAI use only : It may be displayed for IAI use. It is not a code to show the model

type.

[Refer to the catalog or Instruction Manual (DVD) for specification details.]

Precautions in Handling

1. Handling the Packed Unit

y Do not damage or drop. The package is not applied with any special treatment that enables it to resist

an impact caused by a drop or crash.

y Transport a heavy package with at least more than two operators. Consider an appropriate method for

transportation.

y Keep the unit in a horizontal orientation when placing it on the ground or transporting. Follow the

instruction if there is any for the packaging condition.

y Do not step or sit on the package.

y Do not put any load that may cause a deformation or breakage of the package.

2. Handling the Actuator After Unpacking

y Do not carry the actuator by its motor unit or its cable or attempt to move it by pulling the

cable.

y Hold the frame or motor cover section of the body when transporting the actuator main body.

y Do not hit or drop the actuator during transportation.

y Do not attempt to force any part of the actuator. Do not apply excess force especially on the fingers,

finger guide and levers.

y In case of removing the grease applied on the fingers and finger guides after delivery, make sure to

implement a rust prevention treatment.

There is grease applied on the fingers and finger guides at the delivery for rust prevention treatment.

The fingers and finger guides may gather rust if the grease is wiped away.

Also, have grease or an anti-rust agent applied on the fingers and finger guides regularly.

[Refer to 5.4.1 Applicable Greases for the Guide, Finger and Finger Guide in 5.4 Grease Supply in

Instruction Manual]

Environments for Installation, Storage and Preservation

1. Installation Environment

The actuator should be installed in a location other than those specified below.

Also provide sufficient work space required for maintenance inspection.

y Where the actuator receives radiant heat from strong heat sources such as heat treatment furnaces

y Where the ambient temperature exceeds the range of 0 to 40°C

y Where the temperature changes rapidly and condensation occurs

y Where relative humidity smaller than 20% or larger than 85%RH

y Where the actuator receives direct sunlight

y Where the actuator is exposed to corrosive or combustible gases

y Where the ambient air contains a large amount of powder dust, salt or iron (at level exceeding what is

normally expected in an assembly plant)

y Where the actuator is subject to splashed water, oil (including oil mist or cutting fluid) or chemical

solutions

y Where the actuator receives impact or vibration

y Place with an altitude of 2,000m or more

If the actuator is used in any of the following locations, provide sufficient shielding measures:

y Where noise generates due to static electricity, etc.

y Where the actuator is subject to a strong electric or magnetic field

y Where the actuator is subject to ultraviolet ray or radiation

2. Storage • Preservation Environment

y The storage and preservation environment should comply with the same standards as those for the

installation environment. In particular, when the machine is to be stored for a long time, pay close

attention to environmental conditions so that no dew condensation forms.

y Unless specially specified, moisture absorbency protection is not included in the package when the

machine is delivered. In the case that the machine is to be stored and preserved in an environment

where dew condensation is anticipated, take the condensation preventive measures from outside of

the entire package, or directly after opening the package.

y For storage and preservation temperature, the machine withstands temperatures up to 60°C for a

short time, but in the case of the storage and preservation period of 1 month or more, control the

temperature to 50°C or less.

y Storage and preservation should be performed in the horizontal condition. In the case it is stored in

the packaged condition, follow the posture instruction if any displayed on the package.

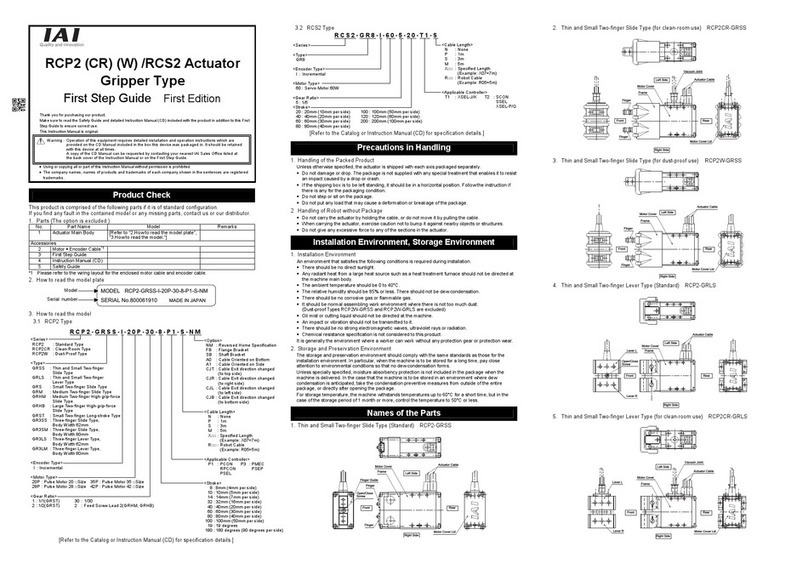

Names of the Parts

1. Slide Type GRSML, GRSLL, GRSWL

2. Lever Type GRLM, GRLL, GRLW

Open/Close Screw

Actuator Cable

Motor Cover

Frame

Motor Cover Cap

Lever

[For the details of dimensions and outlines, refer to the catalog or Instruction Manual (DVD).]

Attachment

Refer to the Instruction Manual (DVD) for the attachments of the actuator and loads.

[Precautions for Attachments]

No. Item Precautions

1Attachment Surface • Make sure that the surface to install the actuator and that used as the

datum are a well-finished machined surface or one that possesses an

accuracy equivalent to it.

• Have enough space for the maintenance work.

2Bolt to be used • For the bolts to be used, a high-tensile bolt complying with ISO-10.9 or

more is recommended.

• If using the tapped holes, use screws with the thread length dimension

being less than the effective depth of the holes.

• For the actuator mounting, use a bolt with the dimension of its effective

mating length to the tapped hole is as stated below.

If tapped hole on steel → thread length same as nominal diameter

If tapped hole on aluminum → thread length 1.8 times longer than

nominal diameter

3Tightening Torque • Please follow the specification values stated in the Instruction Manual

(DVD) for the tightening torque.

Failure to do so may cause an operation problem.

4Load Moment • Please follow the specification values stated in the Instruction Manual

(DVD) for the load moment.

Applying load exceeding the allowable load moment may cause a drop

in the product life. If it is extreme, flaking may occur.

Product Check

MODEL RCP4-GRSML-I-28P-30-10-P3-P-NW

SERIAL No.000090266 MADE IN JAPAN

CP4

GRSML - I - 28P - 30 - 10 - P3

P

NW - * *

Series

<Type>

Slide Type

Medium types:

GRSML

Large types:

GRSLL

Extra-large types:

GRSWL

Lever Type

Medium type:

GRLM

Large type:

GRLL

Extra-large type:

GRLW

<Encoder Type>

I : Incremental

<Motor Type>

28P : 28□ size

35P : 35□ size

42P : 42□ size

<Deceleration Ratio>

30 : 1/30

28 : 1/28

Identification for IAI use only(Note1)

<Options>

NM : Reversed-home

specification

AC1 : Actuator cable 1m

specification

<Cable Length>

N : None

P : 1m

S : 3m

M : 5m

X□□ : Length specification

R□□ : Robot cable

<Controller>

P3 : PCON-CA

MSEP

<Stroke>

Model

Serial numbe

Warning : Operation of this equipment requires detailed installation and operation instructions which are

provided on the CD/DVD Manual included in the box this device was packaged in. It should be

retained with this device at all times.

A hard copy of Manual can be requested by contacting your nearest IAI Sales Office listed at

the back cove

of the Instruction Manual or on the First Step Guide.

Actuator Cable

Finger Guide

Motor Cover

Frame

Open/Close Screw

Finger

Motor Cover Cap

Finger Guide

Finger