Table of Contents

Table of Contents

Safety Guide.................................................................................................................................. 1

Introduction.................................................................................................................................... 1

Part 1 Installation ....................................................................................................................... 4

Chapter 1 Safety Precautions............................................................................................................... 4

Chapter 2 Warranty Period and Scope of Warranty ............................................................................. 5

1. Warranty Period........................................................................................................................... 5

2. Scope of Warranty ....................................................................................................................... 5

3. Scope of Service ......................................................................................................................... 5

Chapter 3 Installation Environment and Selection of Auxiliary Power Devices.................................... 6

1. Installation Environment .............................................................................................................. 6

2. Heat Radiation and Installation.................................................................................................... 7

3. Selection of Auxiliary Power Devices .......................................................................................... 8

4. Noise Control Measures and Grounding ................................................................................... 13

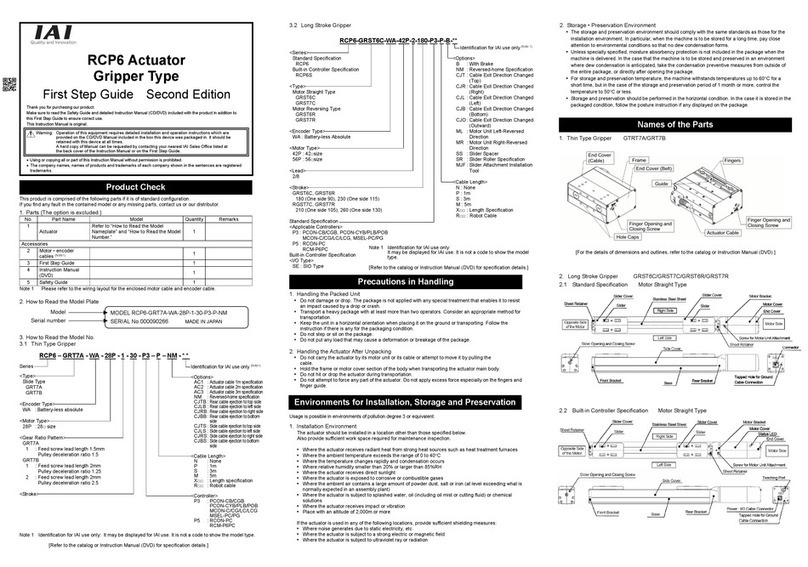

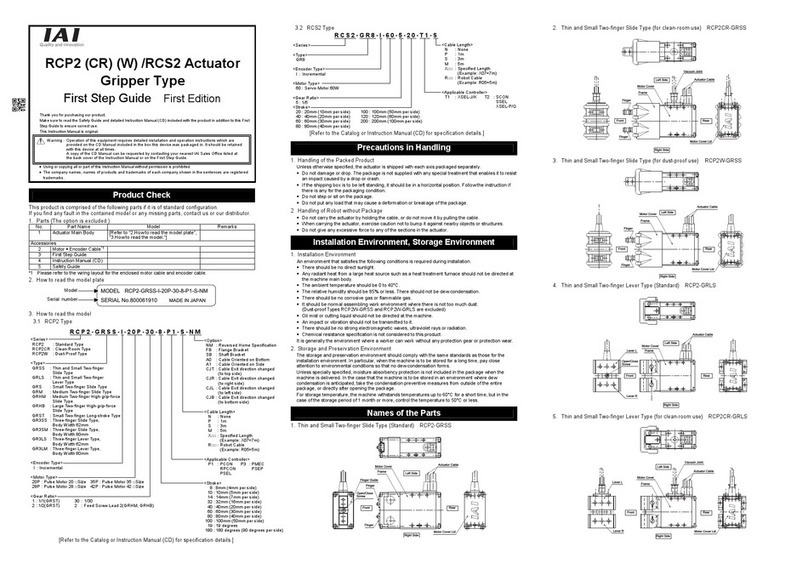

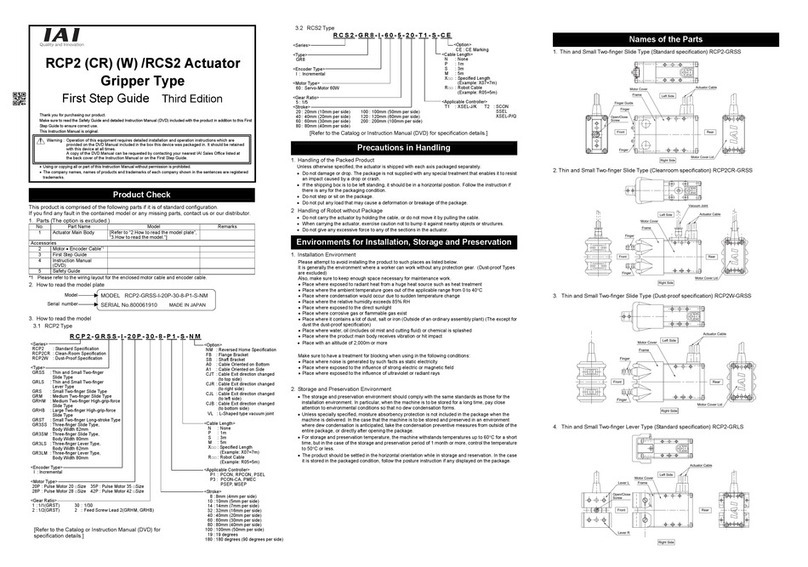

Chapter 4 Name and Function of Each Part....................................................................................... 16

1. Front View of Controller............................................................................................................. 16

2. Explanation of Codes Displayed on the Panel Window ............................................................ 30

2.1 Application....................................................................................................................... 30

2.2 Core................................................................................................................................. 31

2.3 Current Monitor and Variable Monitor ............................................................................. 32

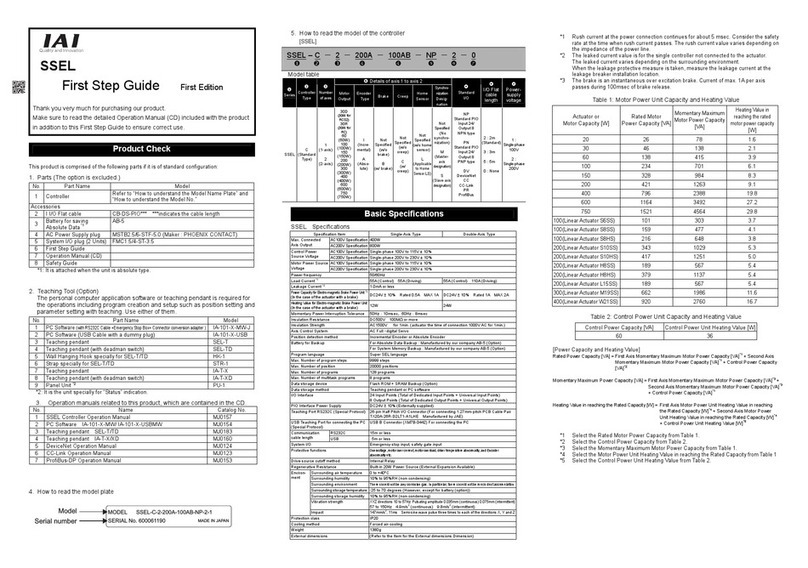

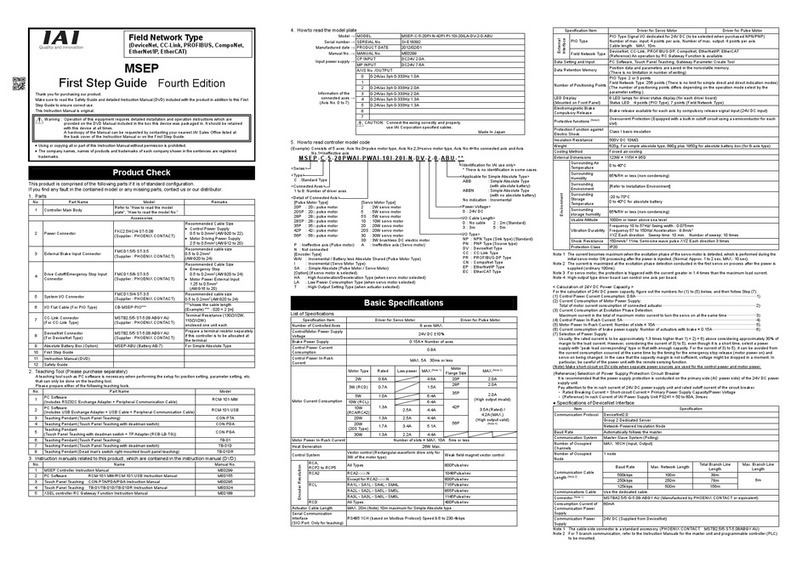

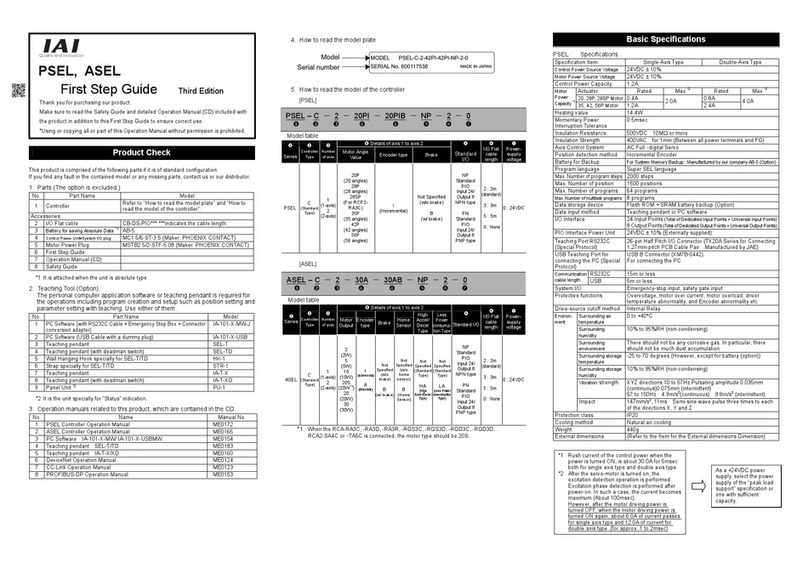

Chapter 5 Specifications..................................................................................................................... 34

1. Controller Specifications ............................................................................................................ 34

2. External I/O Specifications......................................................................................................... 38

2.1. NPN Specification............................................................................................................ 38

2.2. PNP Specification............................................................................................................ 40

3. Power Source Capacity and Heat Output ................................................................................. 42

4. External Dimensions.................................................................................................................. 48

Chapter 6 Safety Circuit...................................................................................................................... 57

1. Items to Notes ........................................................................................................................... 57

2. Safety Circuit for PX Type (Standard Specification) Controller ................................................. 58

3. Safety Circuit for QX Type (Global Specification) Controller ..................................................... 60

4. Timing Chart of Safety Circuit for QX-type SEL Controller........................................................ 65

Chapter 7 System Setup..................................................................................................................... 74

1. Connection Method of Controller and Actuator ......................................................................... 74

2. I/O Connection Diagram ............................................................................................................ 78

3. Multipoint DIO Board ................................................................................................................. 81

3.1 Overview ......................................................................................................................... 81

3.2 Specifications .................................................................................................................. 81

3.3 External Interface Specifications ..................................................................................... 82

3.4 Multipoint I/O Board Connection Cables......................................................................... 83

3.5 Multipoint I/O Board Connection Cables......................................................................... 84

3.6 I/O Circuits....................................................................................................................... 85