EACH

SECTION

of the control panels is assigned a number

under

which

the

hubs are briefly described. Shaded areas indicate

special features.

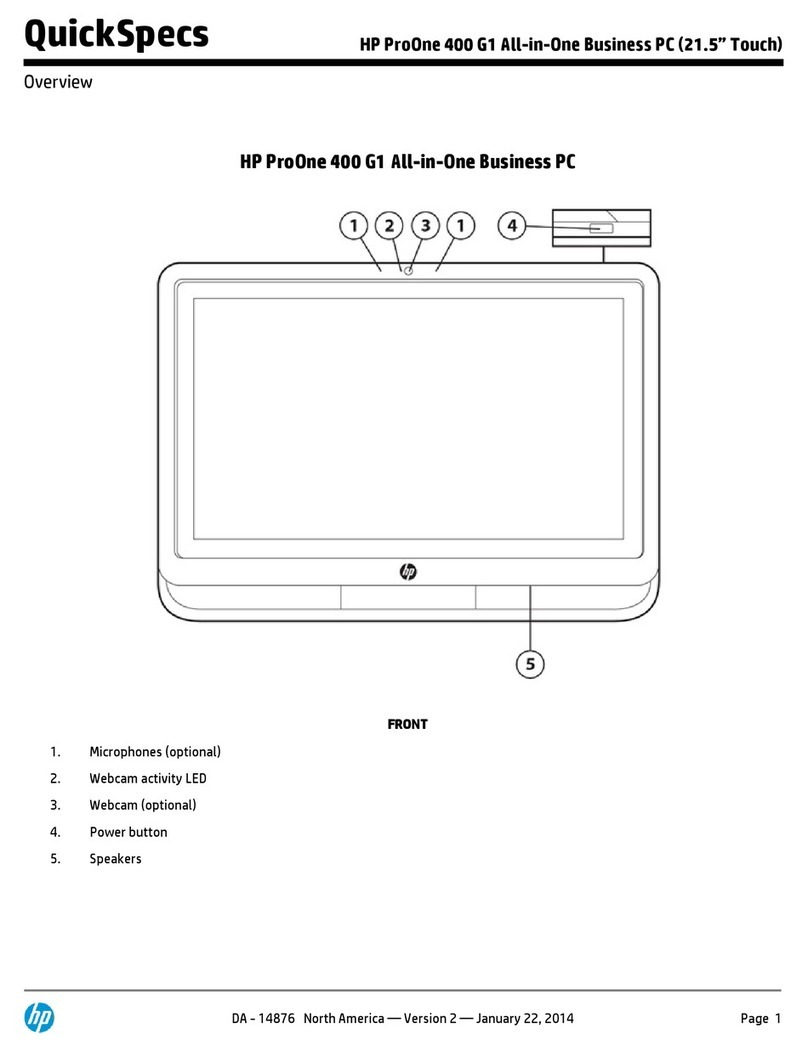

Process Control Panel (Figure 1)

1.

Program

Exits. These hubs emit an impulse whenever the

corresponding program exit occurs

in

an instruction.

The

impulse

is used to make tests on the control panel, and to transfer

program control to the first step

of

a new sequence

of

instructions.

When

one

of

these hubs emits, the program sequence is halted,

and

must

be restarted by impulsing program advance

or

by im-

pulsing

program entries.

When

Program Exit Split

is

installed, either the upper

or

lower exit hubs

of

a

group

will emit depending on which control

hub

was impulsed last.

2.

Dual

Access. These hubs provide control over the mode of

Dual

Access operation.

When

the C

(common)

hub is not wired

to the SEL (select) hub, the access arms operate

in

the automatic

sequence mode.

With

the C

hub

wired to the SEL hub, either the

o

(zero)

or

1 hub may be impulsed from a Program Exit, Cycle

Delay

or

any

other

impulse originating on the 305 panel, except

CI

(control

impulses),

and the

upper

hub

of

the Inquiry

ON

switch.

The

corresponding access

unit

will then accept all

J,

Record Advances, Skip-To-Record, and R instructions until the

other

access

unit

hub

is impulsed.

If·

the C

hub

is permanently

wired

to

either

access

unit

hub

(0

or

1)

the system will then

function

as

a single access system using this unit.

3.

DPIS

(Dual

Process

Interlock

Suspend).

When

the

PU

hub

of

DPIS

is impulsed by either system

in

Dual

System Control,

it

suspends the interlock

that

prevents reading

or

writing

a record

until the arm

of

the

other

system has moved from this same

address.

When

the

PU

hub

is impulsed on one process control

panel, it suspends the interlock for both systems; however, only

the system initiating the suspension can re-establish

the

interlock

by impulsing

the

DO hub.

If

PU

has been impulsed

on

both sys-

tems, the DO

hub

on both process control panels must be impulsed.

When

a system impulses

PU,

it

cannot write in the file; a write

instruction causes a file check. A light on the console

of

each

system indicates

when

the interlock is suspended for that system.

4.

ALC

(Automatic

Last

Card).

If

the ALC switch is

not

plugged

(when

the cards have

run

out

of

the card reader hopper,

and

the last card has passed the second reading

brushes),

the

card reader

will

stop.

The

operator may depress the Reader Start

key, and feed

the

last cards to the stacker.

Just

after the operator

depresses the Start key, the last card selector transfers.

If

the ALC switch is plugged, the card reader

will

feed cards

for one additional cycle before stopping.

During

this additional

cycle the last card selector transfers,

and

any last-card routines

that

have been programmed utilizing the last card selector can be

completed.

The

cards may then be fed into the stacker by depress-

ing

the

Reader Start key.

5.

Inquire.

The

pair

of

hubs marked

ON

form a switch that is

jackplugged if manual inquiries to the disk records are to be

allowed

during

processing.

The

IN-OUT

hubs form an interlock

that

is wired to allow the

console to take control

of

the access arm

at

a time

when

it

will

not

countermand the stored program instructions.

The

inquire

interlock is

wired

in

the program

at

a

point

where

the

access arm

Control Panel Summary

has completed its use

of

the record.

If

the arm is about to be

moved by the program, no harm will be done

if

the operator

moves the access arm to some other record to make an inquiry.

When

the record has been obtained

for

the operator, the stored

program resumes control and moves the arm to the next record

required.

A

program

exit

wired

into

the

IN

hub

emerges

immediately

from

the

OUT

hub

if

no

inquiry

has

been

set

up

at

the

con-

sole

or

is

delayed

if

an

inquiry

is

set

up.

The

impulse

from

the

OUT

hub

is

wired

to

initiate

the

next

program

step.

6.

ITI

(Inquiry-Type

Interlock).

The

typewriter may be used

to make inquiries to the disk records

as

described in item 5.

The

typewriter may also be used as a secondary

output

printer

by ad-

dressing the

output

record to Q track and impulsing

TYPE

on the

control panel (see item

33).

If

both

of

these uses occur in the

same program, the inquiry-type interlock must be jackplugged to

prevent an inquiry from taking place while the typewriter is under

program control.

7.

File

Interlock.

This interlock is provided so that

new

pro-

grams may be tested

without

changing the information

on

the

disks.

When

a program has been checked out, this switch is wired

to allow

the

disk records to be changed. All operations except

writing

on the disks may be performed

with

the interlock off.

A write operation

will

cause a file check.

8.

Accumulator

Sign. Each accumulator has an associated

selector that shows its sign. By using a program exit impulse, a

test may be made to determine

if

an accumulator is positive, stands

at zero,

or

is negative.

9.

Accumulator

Overflow.

Whenever

an accumulator over-

flows (tries to accumulate a number beyond its capacity), a

path

is established between each

IN

hub

and its YES hub.

These

paths

remain set

up

until

the

accumulator overflow selector is dropped

out

by impulsing DO. A normal

path

is established between the

IN

hub and the corresponding

NO

hubs

when

the selector is

dropped

out

or

when no overflow has occurred.

10.

Character

Selectors

..

The

character selectors provide a way

of

analyzing any character on a

drum

track.

The

position to be

analyzed is entered into this

unit

by an instruction

with

hyphen

(-99)

as

the

TO

address. Any character entered establishes test

paths between each

IN

hub

and the exit hubs corresponding to

the character entered.

Four

distinct

paths

are set

up

on the basic machine.

Three

of

the paths are arranged so that a test impulse entered into

the

IN

hub

emerges from

the

hubs corresponding to the

IBM

card code

of

the character being tested.

In

the fourth path, an impulse wired

into the

IN

hub

emerges from one

of

the 48 exit hubs representing

the

specific letters, numbers, and special characters

(including

blank).

The

test paths remain set up until another character is

addressed to the unit.

The

special feature X

no-X

and

0

no-O

bit

selectors provide

analysis

for

the presence

or

absence

of

these bits

in

the character

sent to the character selector.

11.

Blank

Transmission.

A 6

in

the tenth position

of

an

in-

struction causes

the

Blank Transmission selector to reset to a

NO

condition.

If

the information transferred

from

the core storage

during

the execution of the instruction is all zeros

or

blanks, the

selector

will

transfer to a YES condition and the

BLANK

light

on

the 380 Console will be

turned

on.

The

selector will remain trans-

ferred

and

the

light

will remain on until another instruction

with

a 6 is read.

REFERENCE

SUMMARY

11