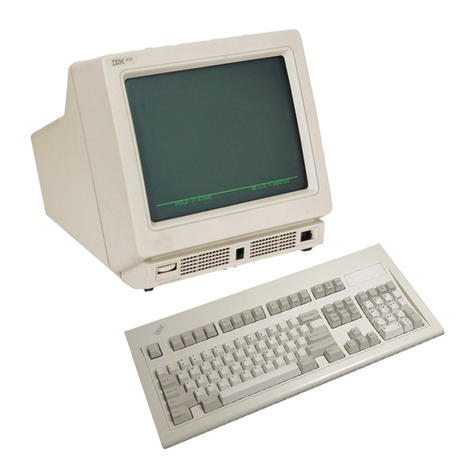

3279

MIM

Preface

Part

2 comprises the Maintenance Analysis

Procedures.

ii

This publication contains the information needed

to

service

and

maintain the IBM

3279

Color Display

Station Models 2A, 2B, 3A,

and

3B.

Part 1 comprises the Maintenance Information

and

Parts Catalog.

If

this machine

is

fitted with

any

RPQ

features,

any

extra

RPQ

documentation

can

he

found

in

a

tray

under

the keyboard.

Fourth Edition, November 1981

This is a major revision of,

and

obsoletes, SY33-0069-2.

The

drawings

and

specifications contained herein shall

not

he reproduced

in

whole

or

in

part without written permission.

IBM has prepared this maintenance manual for the use of IBM customer

engineers in the installation. maintenance, or repair

of

the specific

machines indicated. IBM makes no representations

that

it is suitable for

any

other

purpose.

Information contained in this manual

is

subject

to

change from time

to

time.

Any

sllch change will be reported in subsequent revisions

or

Technical Newsletters.

It

is possible

that

this material may contain references to,

or

information

abollt, IBM products (machines or programs), programming,

or

services

that

are

not

announced in your country. Such references

or

information

must

not

be construed

to

mean

that

IBM intends

to

announce such IBM

products, programming,

or

services in your country.

Publications are not stocked

at

the addresses given below; requests for

IBM publications should be made

to

your IBM representative

or

to

the

IBM

branch

office serving your locality.

A form for reader's comments

is

provided

at

the back

of

this publication;

if the form has been removed, comments may be addressed

to

either:

• International Business Machines Corporation, Department

812H,

1133 Westchester Avenue, White Plains,

New

York 10604.

or

IBM United Kingdom Laboratories Limited,

Product

Publications, Mail

Point 95, Hursley Park, Winchester, Hampshire

S021

2JN, England.

IBM may use or distribute whatever information you supply

in

any

way

it

believes appropriate without incurring

any

obligation

to

you.

e Copyright International Business Machines Corporation 1979, 1980,

1981