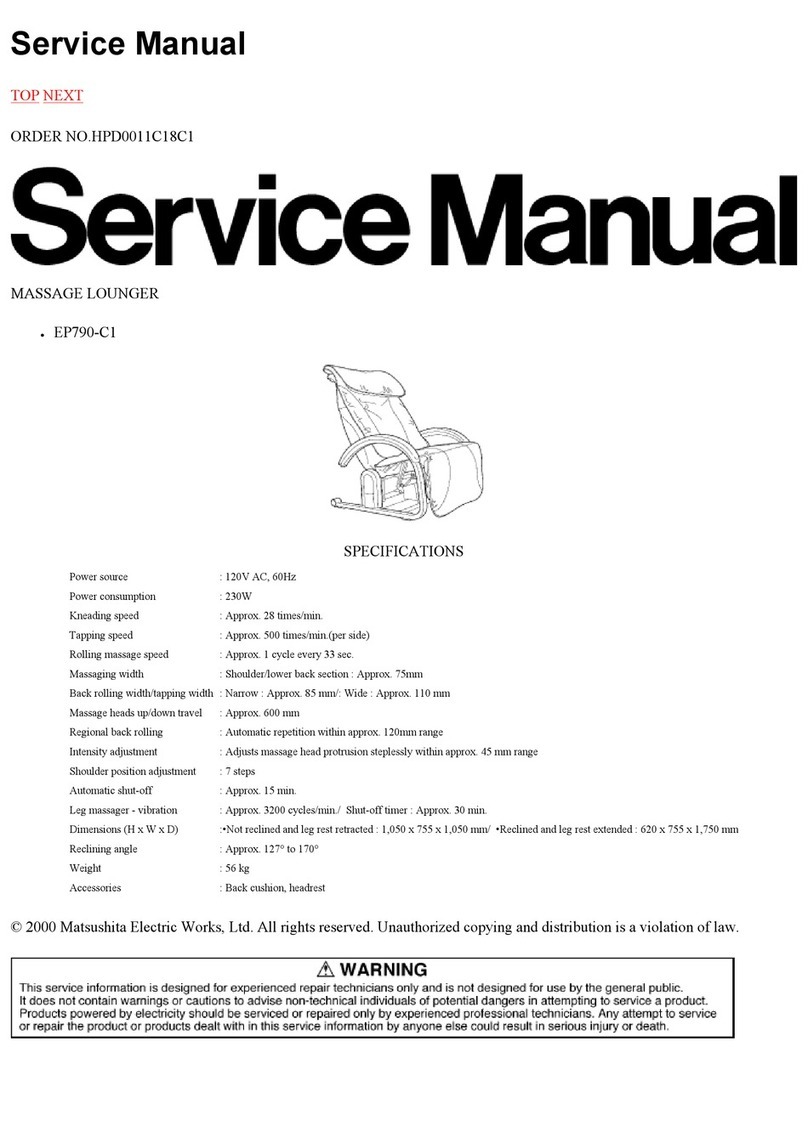

Section Three: Troubleshooting/Circuit Analysis

Refer to figure 3, power supply board schematic diagram analysis, or just replace

the board

Wire of remote

controller failure,

change it——

OK

Main PCB

board failure,

buttons

damage or

other reason,

replace the

wrong parts

——OK

Figure 3,Check if there’s any

loosen on the power switch or

plug, make sure there’s

AC220V power input; then

check if the fuse was burned

or not, if yes, replace it

No burning

again after

replaceme

nt——OK

Continue burning after

replacement, then turn to figure 3

and 4, check if there’s something

failure on main PCB board,

transformer or other parts

①Transformer coil burning

→cause the fuse

burning

②Transformer coil open→

no normal output

voltage

Refer to Section two to

distinguish the parameters of

transformer or charged

voltage measurement

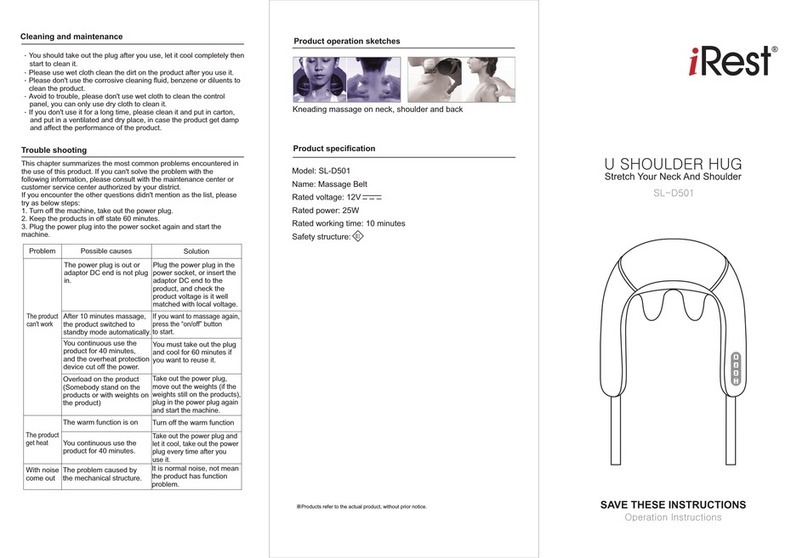

method, as shown in figure 1,

measuring the input & output

voltage of transformer after

remote controller working

1. Power supply or power drive failure

2.Remote controller failure

3 .Transformer A38-220V-24V failure

The massage chair doesn’t work

DC5V switch

power failure

Other faults/power

board light, lighting

or not

Refer to physical map 4, 100471K MOV was broken

Refer to physical map 4, DCSV light doesn’t light

Refer to

physical

map 5,

schematic

diagram

analysis

Refer to physical map 4, commutation diode 4007, integrated TNY274,

optocoupler 817 or transformer JY1905 damage all would cause no DC5V

switch power supply

→remote controller and IC does not work( or no working voltage in relay

105LM coil, so the transformer A380-220V-24V without power supply)

→massage chair does not work

Replace the defective components or the whole drive board

Figure 1,Driving board failure

Figure 3, The schematic diagram of power supply part

on power supply board

This piezoresistor 10D471K

breakdown, will cause the input

power supply cutting-out, then cause

the fuse burning

Defective relay 105LM cause AC220V cannot

supply to transformer, then the massage chair

cannot start the massage functions

This audion S8050 on Q7 control the

relay coil flux or power cut