7

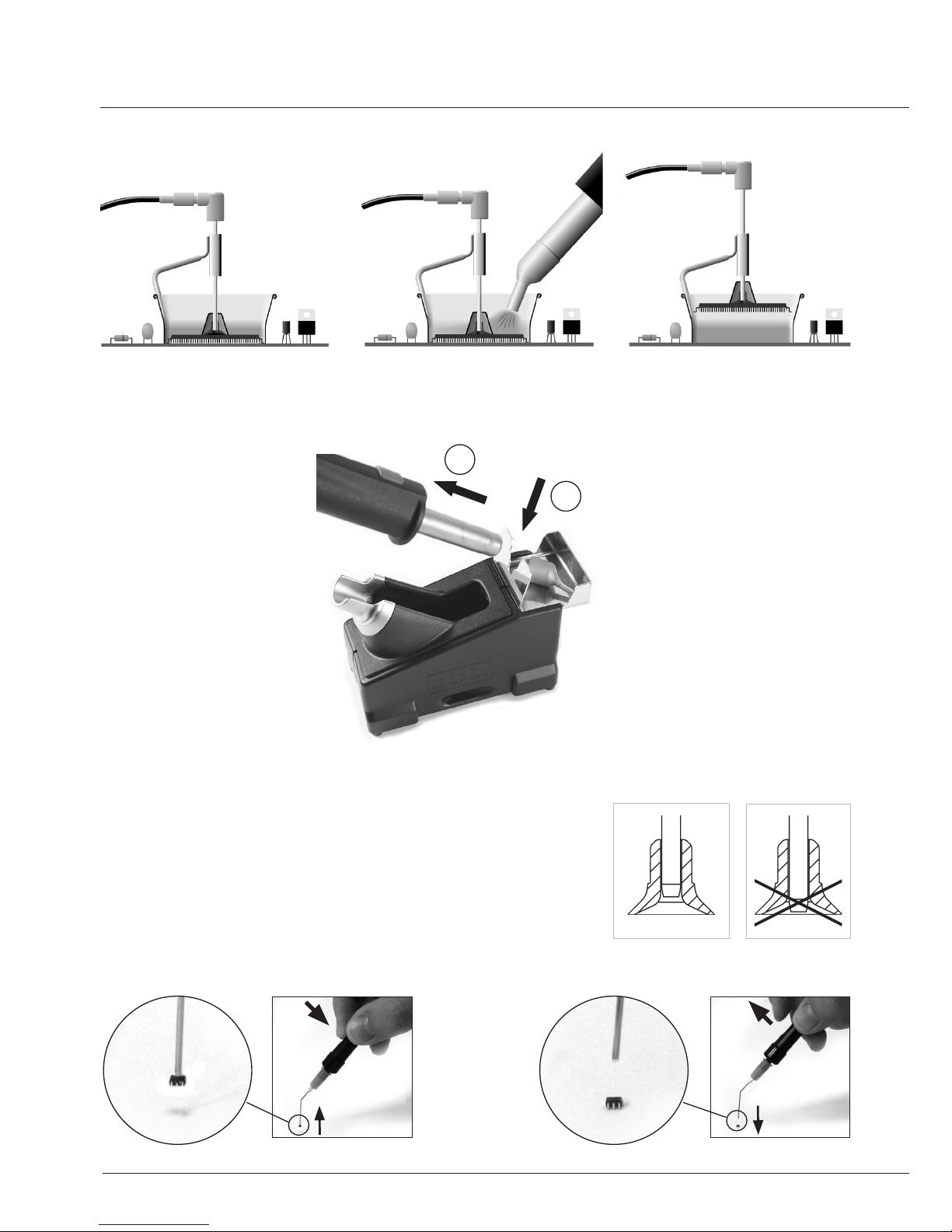

FOLLOW THIS PROCESS INVERTED TO RE-CONNECT THE HEATING ELEMENT

This step has to be performed when the tool is stopped and the heating set is cold.

1. Untighten screw.

2. Separate the heating element from the heating set’s handle.

3. Connect the new heating element, pushing it’s extreme.

4. Insert screw to avoid air-loss which could reduce the heating element’s lifetime.

0011070 (230V) or

0007565 (100V-120V)

Heating element

0009829

Handle

JT-T2A (230V) or

JT-T1A (100V-120V)

Heating set

REPLACING THE HEATING ELEMENT

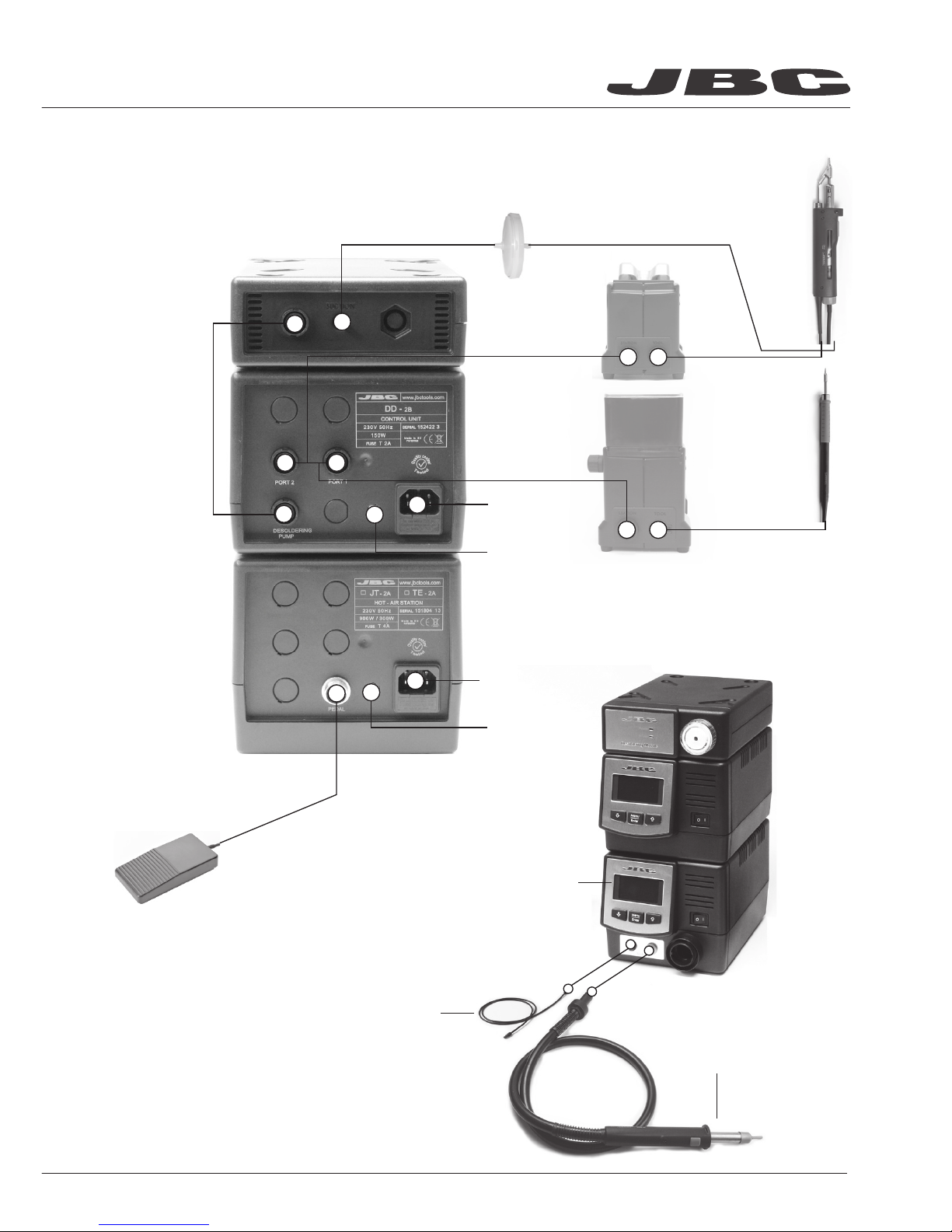

CHANGING THE HEATING SET

1. Ensure that the tool is stopped

2. Use a wrench to unscrew the cover

3. Pull back the seal

4. Pull connector from the socket to disconnect

the heating set from the station

5. Follow steps in reverse

to connect the heating set