2 3

Index

Packing list ...........................................................4

JT Hot Air station

Features .............................................................. 8

Stand & Nozzle changer ................................ 9

Protectors & Extractors ................................10

T260 Pick & Place ..........................................11

Operation & Process Control with JT .......12

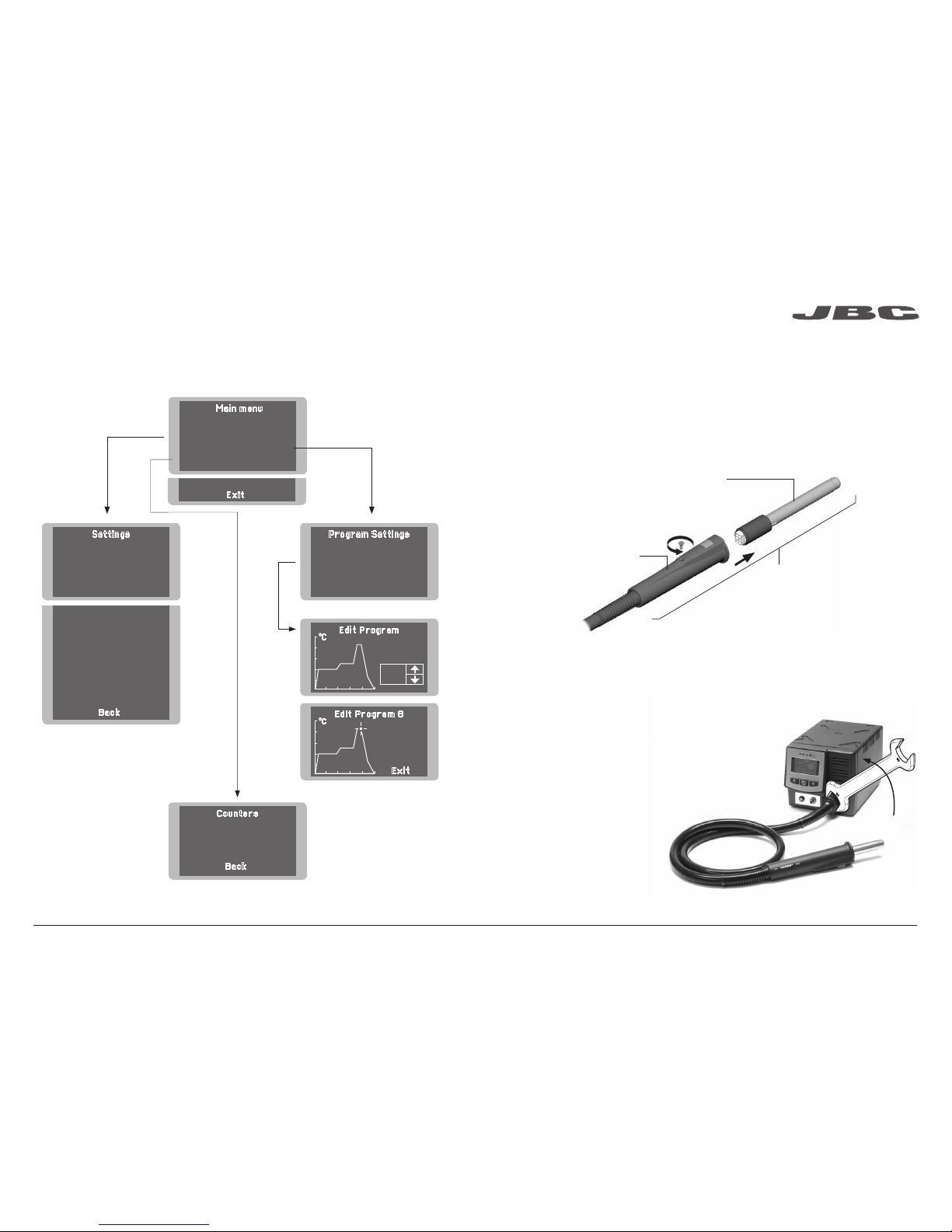

JT-TA Replacing the Heating Element ......15

JT-TA Changing the Heater Hose Set ...... 15

DDE Control Unit & MVE Module

Features ............................................................16

Stands & Tip Cleaner ....................................18

T245 Changing Cartridges ..........................20

DR560 Changing Tips .................................. 21

DR560 Changing the Heating Element ... 22

DR560 Tin Deposit Cleaning ...................... 23

DR560 Tip Care ..............................................24

Desoldering Process DDE & MVE .............24

MVE Initial Setup ............................................25

MVE Changing the pump filters .................25

Operation with DDE ...................................... 26

Process Analysis ............................................28

Soldering Net .................................................. 29

Working with robots ......................................30

Station Sotware ..............................................30

Maintenance ..................................................... 31

Safety ...................................................................32

Specifications .................................................. 33

Exploded View ................................................. 66

www.jbctools.com