9

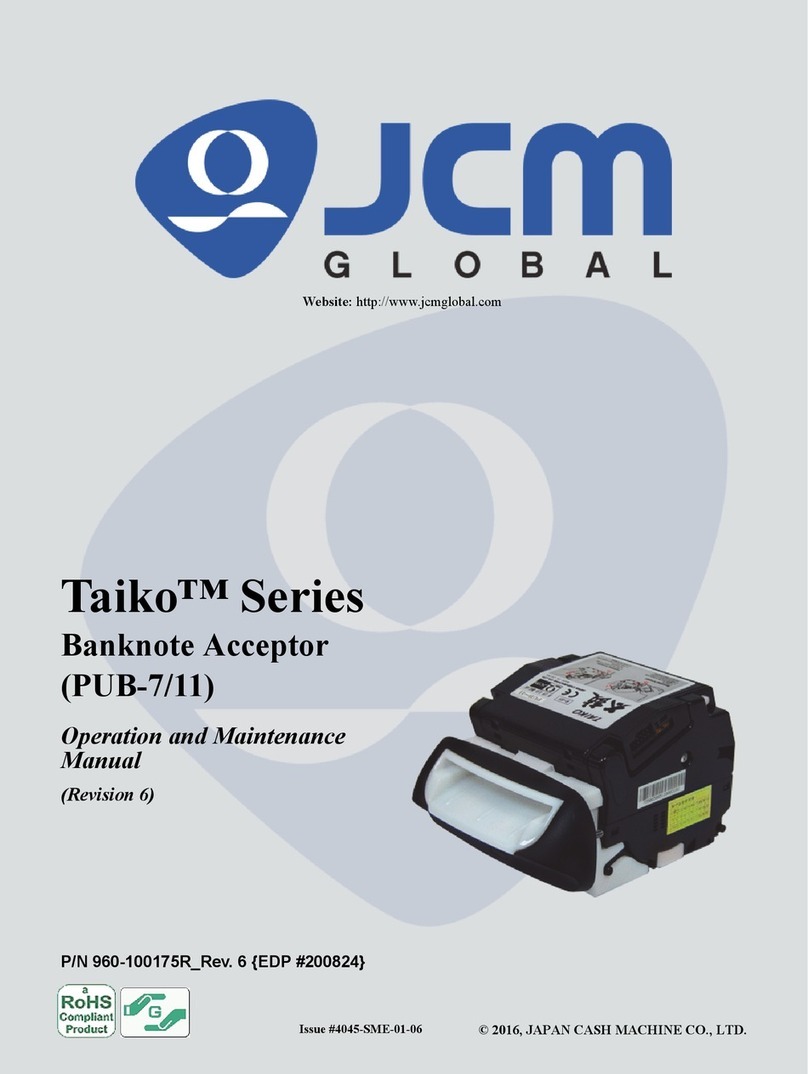

TAIKO Service Manual

Preface

© 2006 Japan Cash Machine Co.Ltd. All rights reserved.

2-4. External Dimensions .......................................................................................... 2-11

2-4-1. When installing the Type 1/ Type 2/ Type 3 faceplate with TAIKO unit................... 2-11

2-4-2. When installing the Type 5 faceplate with TAIKO unit ............................................. 2-12

2-5. DIP Switch Setting .............................................................................................2-13

2-5-1. Basic Settings

X4: ID-003 (serial)/ MDB/ Pulse/ ccTalk specification ................................................. 2-14

2-5-2. Basic Settings

01 : ID-001 (parallel) specification ................................................................................. 2-14

2-6-3. Special Settings ............................................................................................................... 2-14

Chapter 3 Installation / Operation

3-1. Installation/Removal ............................................................................................ 3-2

3-2. Wiring....................................................................................................................3-5

3-2-1. Recommended Parts ........................................................................................................ 3-5

3-2-1-1. Reccomended Parts

X4: ID-003 (serial)/ MDB/ Pulse/ ccTalk specification .......................................... 3-5

3-2-1-2. Reccomended Parts

01 : ID-001 (parallel) specification .......................................................................... 3-5

3-2-2. Wiring Procedure ............................................................................................................. 3-6

3-3. Clearing Bill JAM ................................................................................................3-7

Chapter 4 Download / Adjustment

4-1. Download ..............................................................................................................4-2

4-1-1. Requirements .................................................................................................................... 4-2

4-1-2. Connecting Procecedure .................................................................................................. 4-3

4-1-3. Download Procedure ........................................................................................................ 4-4

4-1-4. Writing Serial No.............................................................................................................. 4-5

4-2. Adjustment............................................................................................................4-6

4-2-1. Requirements .................................................................................................................... 4-6

4-2-2. Adjustment Procedure ..................................................................................................... 4-6

4-3. Palm.......................................................................................................................4-8

4-3-1. Requirement...................................................................................................................... 4-8

4-3-2. Installing File Converter (PdbConvEN.exe) .................................................................. 4-8

4-3-3. Converting Software Program ....................................................................................... 4-9

4-3-4. Download Procedure ...................................................................................................... 4-10

4-4. Cloning ................................................................................................................ 4-11

4-4-1. Required Items ............................................................................................................... 4-11

4-4-2. Cloning Procedures ........................................................................................................ 4-11

Chapter 5 Trouble Shooting / Maintenance

5-1. Error Code ............................................................................................................5-2

5-1-1. Error Code ........................................................................................................................ 5-2