V1.00/EN/00643259

Page 2/57Data Sheet 406012

JUMO GmbH & Co. KG

Delivery address: Mackenrodtstraße 14

36039 Fulda, Germany

Postal address:

36035 Fulda, Germany

Phone: +49 661 6003-0

Fax: +49 661 6003-607

Internet: www.jumo.net

JUMO Instrument Co. Ltd.

JUMO House

Temple Bank, Riverway

Harlow, Essex CM20 2DY, UK

Phone: +44 1279 635533

Fax: +44 1279 635262

Internet: www.jumo.co.uk

JUMO Process Control, Inc.

6733 Myers Road

East Syracuse, NY 13057, USA

Phone: 315-437-5866

1-800-554-5866

Fax: 315-437-5860

Internet: www.jumousa.com

40601200T10Z001K000

Description

General information

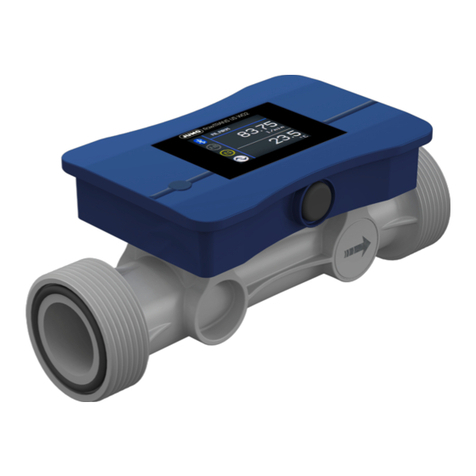

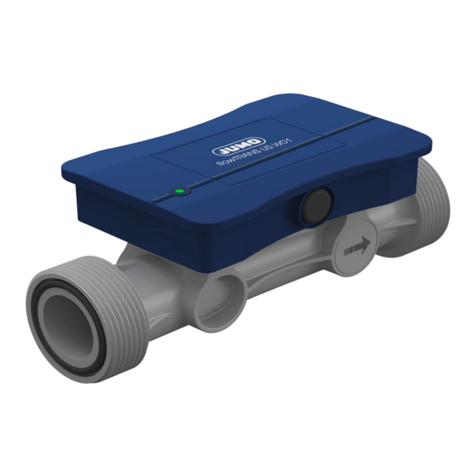

The JUMO flowTRANS MAG S01 was devel-

oped with particular consideration for the

growing requirements that are placed on mod-

ern flowmeters. The modular device concept

offers flexibility, cost-effective operation, and

excellent reliability with a long operating life

and minimal maintenance costs.

Diagnostics functions

State-of-the-art diagnostics functions such as

"empty pipe detection" and "sensor measure-

ment" monitor the functional capability of the

device and the process.

The limit values for the diagnosis parameters

can be adjusted on-site. If these limit values

are exceeded, an alarm is issued.

The diagnosis data can be extracted via a

state-of-the-art Device Type Manager (DTM)

for further analysis. Critical states can there-

fore be detected at an early stage and

countermeasures can be taken.

This enables higher productivity and avoids

down times.

Status messages are classified in accordance

with the NAMUR requirements.

In the event of a fault, a diagnosis-based help

text is displayed which makes it significantly

easier and quicker to rectify the fault. This pro-

vides maximum process reliability.

Sensor

Self-cleaning, double-sealing polished mea-

suring electrodes increase the reliability and

measurement performance of the device.

The high excitation frequency of the sensor

means that the JUMO flowTRANS MAG S01

has a fast response time as a flow metering

system. State-of-the-art filter methods that

separate the measurement signal from the in-

terference signal enable precise measure-

ment with outstanding accuracy even under

difficult conditions (max. measurement devia-

tion 0.2 % of the measured value).

Startup

The latest memory technology in the sensor

eliminates the need to check the assignment

of the sensor and transmitter. The transmitter

detects the sensor automatically using the

built-in "SensorMemory". Once the voltage

supply is switched on, the transmitter carries

out self-configuration. The sensor data and

the measuring-point specific parameters are

loaded automatically. Potential errors are thus

eliminated and startup is quick and reliable.

Operation

The parameters pre-set in the plant are

changed via the user-friendly display and non-

contact operating buttons – quickly and easily

without the need to open the housing. The

easy setup function also guides inexperienced

users smoothly through the configuration, step

by step.

The softkey functionality makes it as easy to

use as a modern cell phone. During configura-

tion, the admissible setting range of the rele-

vant parameter is shown on the display and

inadmissible entries are rejected.

Transmitter

The back-lit display can be turned without ad-

ditional tools. The contrast is adjustable and

the display is fully configurable. The size of the

characters, the number of lines, and the reso-

lution of the display (decimal points) are vari-

able. In multiplex mode, several display

appearances can be flexibly preconfigured

and called up in succession.

The intelligent module design of the transmit-

ter slot enables simple dismantling without un-

screwing cables or removing connectors.

Whether it is for counting pulses (active or

passive), 20 mA (active or passive), status

output (active or passive) – the universal

transmitter always offers the right signal. The

HART protocol is standard here.

Alternatively to the HART® protocol, the trans-

mitter can be equipped with PROFIBUS-PA as

an option.

Conformities

The JUMO flowTRANS MAG S01 complies

with the device standard for the process indus-

try. It meets the various NAMUR require-

ments. In addition, the flowmeter is a universal

device in terms of the Pressure Equipment Di-

rective. In accordance with the NAMUR re-

quirement, the evaluation is performed

according to Category III for pipelines. This

means that the JUMO flowTRANS MAG S01

can be used universally. Costs are reduced

and reliability is improved.

Function overview

The following table provides an overview of

the most important functions.

Device version

The JUMO flowTRANS MAG S01 is available

in a compact and remote mount design type.

Compact: sensor and transmitter form one

mechanical unit.

Remote mount: sensor and transmitter are

placed in separate housings.

The housings are available as single-compart-

ment or dual-compartment housings, depend-

ing on the requirements concerning the Ex-

protection type.

Overview of available versions:

Measuring accuracy

0.4 % (optional 0.2 %) of the measured val-

ue

Additional software functions

Measuring units, editable counters

Graphic display

Line recorder function

Fieldbus

PROFIBUS-PA (optional)

JUMO flowTRANS MAG S01

Compact Remote

mount

Standard Single-com-

partment

Single-com-

partment

No Ex- housing housing

protection

Ex-protec-

tion

Single-com-

partment

Single-com-

partment

Zone 2, 21, housing housing

22

Ex-protec-

tion

Dual-com-

partment

Dual-com-

partment

Zone 1, 21, housing housing

22