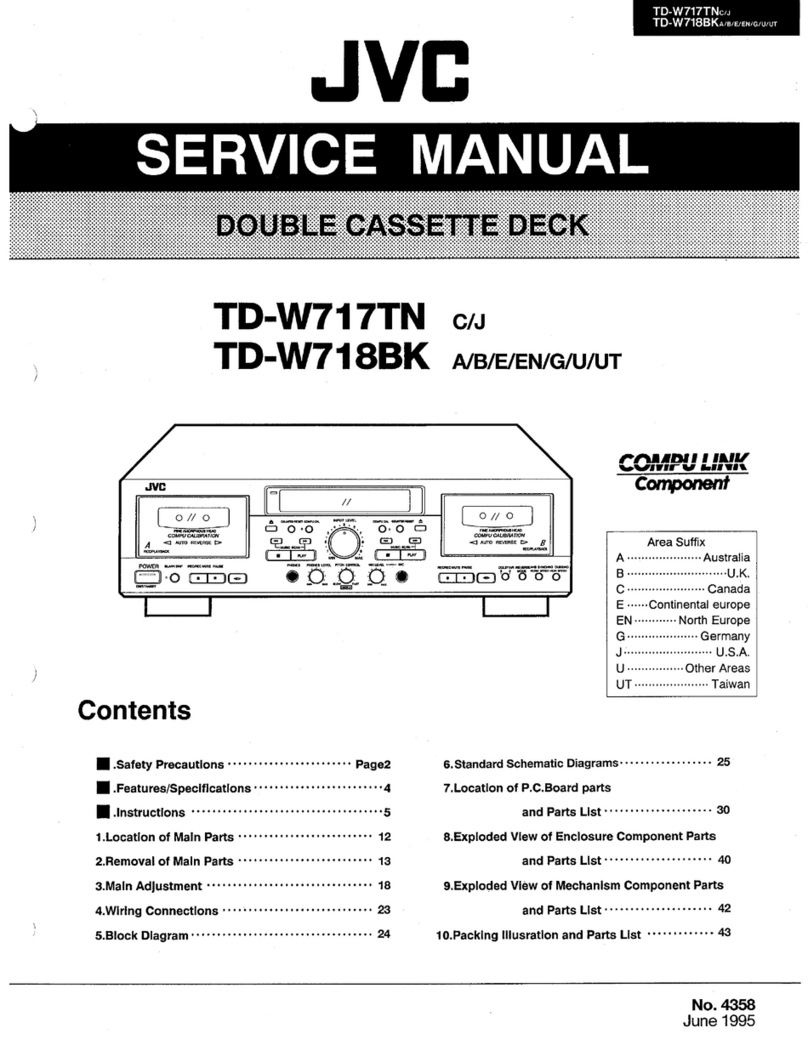

TD-W217TNevs

TD-W218BKweeven/euut

INTRODUCTION

PT

I

TL

a

SE

EY

Thank

you

for

purchasing

JVC

product.

Read

this

instruction

book

carefully

before

operating

to

be

sure

of

getting

optimum

performance

and

longer

service

life

from

the

unit.”

CONTENTS

FOALUCES

eee

iad

dees

sks

coondseneeSvetceess

da

Geies

Recs

ceeecdies

ieee

de

taste cutee

4

CAUTIONS

ica

tess

head

ccsedizavhs

ceessccdesnadadsccchis

febeerdedbsetassundsegeascas

COnNSCHIONS

fisscessee

eects

BE

aoe

seatti

ceed

ES

A

Cassette

loading

.u.......ecciescessecssnseeeeeeiae

eviee

Seteaveasieg

james

Names

of

parts

and

their

functions

Auto

reverse

operation

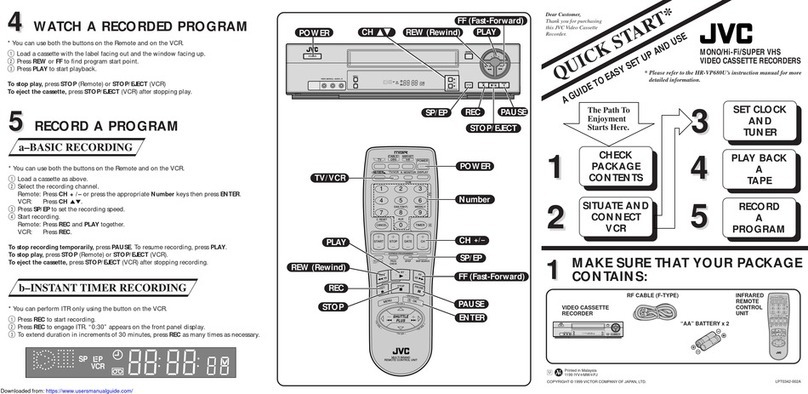

Playback

........ccccccccrecseseneee

RECOIING

0.0...

.eeecececeeeeeeceeeeeeneeeesseeenes

pevtesebetnuedtea

tates

Compu

link

control

system

subgutsustasssuorecntscestecteeh

fate

sabsnisenctvoes

Dubbing

MaintONanCe

sic.

sisiccisseiccssivsessccsvcicvasecoconsenssssnacnoresniescsensoccnes

TrOUDIESHOOTING

«0.0...

rece

eeteceseeeneseeecsnsesssenesesenseseeeeesenseeens

Specifications

.......ccccecsceessssssesssseseeeseeeseeeereees

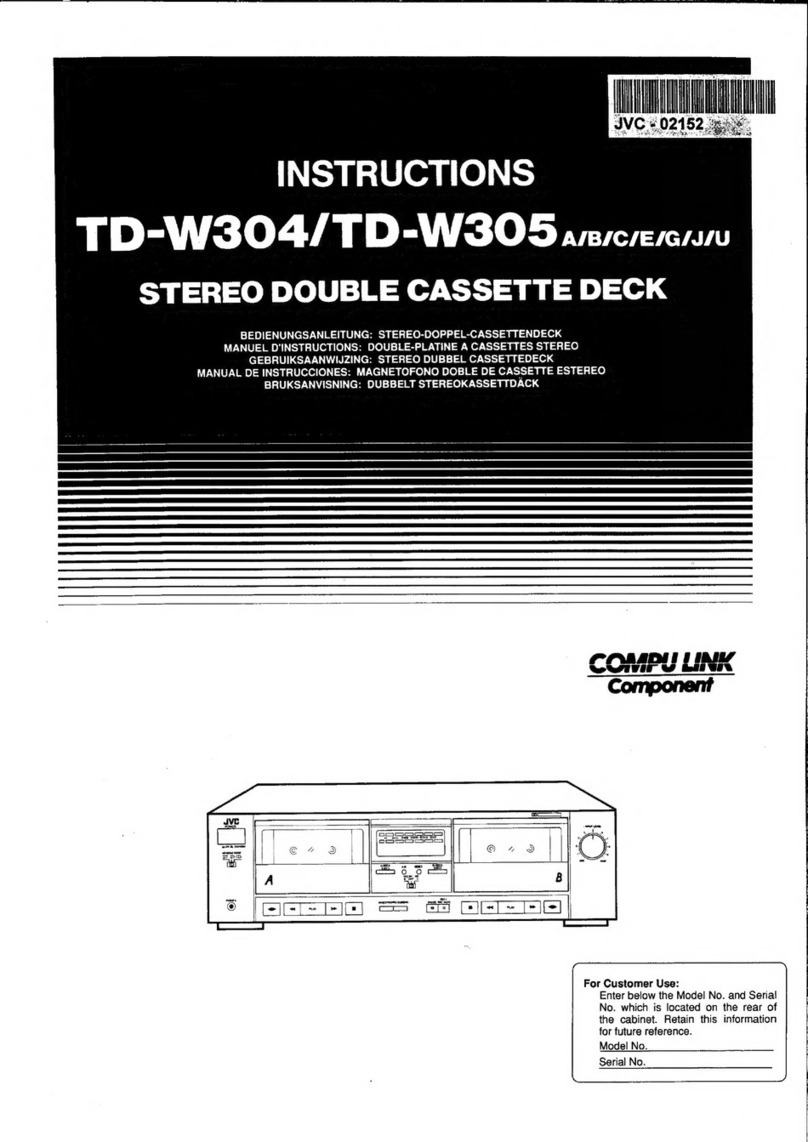

FEATURES

1.

Double

cassette

mechanism

for

recording/playback

and

playback

Recording/playback

mechanism

in

deck

B

and

playback

.

mechanism

in

deck

A

both

with

reverse

head

system.

.

Full

logic

mechanism

.

Dolby*

HX

PRO

headroom

extension

.

Dolby

B

&

C

noise

reduction

system

.

DDRP

(Dynamics

Detection

Recording

Processor)

compatibility

The

DDRP

function

is

possible

only

when

used

with

a

suitable

JVC

CD

player..

.

2-color

FL

peak

level

indicator

7.

Digital

tape

counter

respectively

for

deck

A

and

deck

B

8.

Synchro

start

(normal-/high-speed)

dubbing

_9.

Auto

tape

select

mechanism

(decks

A

and

B)

10.

COMPU

LINK-3

compatible

aoPpon

fo)

*

Dolby

noise

reduction

and

HX

Pro

headroom

extension

manufactured

under

license

from

Dolby

Laboratories

Licensing

Corporation.

HX

Pro

originated

by

Bang

&-Olufsen.

“Dolby”,

the

double-D

symbol

OO

and

“HX

PRO”

are

trademarks

of

Dolby

Laboratories

Licensing

Corporation.

COVRADI

LT

Iniie

WHIVIT

WD

MEST

Control

System

COMPU

LINK

control

system

is

the

convenient

system

using

COMPU

LINK-3/SYNCHRO

terminals

on

the

rear

panel.

(See

pages

4

and

8)

6

(No.

4357)

CAUTIONS

1.

Prevention

of

Electric

Shocks,

:Fire

Hazards

and

Damage

=

Se

rote.

1)

Even

when

the

POWER

switch

is

set

to

STANDBY,

a

very

small

current

will

flow.

To

save

power

and

for

safety

when

not

using

the

unit

for

an

extended

period

of

time,

disconnect

the

power

cord

from

the

household

AC

outlet.

2)

Do

not

handle

the

power

cord

with

wet

hands.

3)

When

unplugging

from

the

wall

outlet,

always

grasp

and

pull

the

plug,

not

the

power

cord.

4)Consult

your

nearest

dealer

when

damage,

disconnection,

or

contact

failure

is

found

with

the

cord.

5)

Do

not

bend

the

cord

sharply,

or

pull

or

twist

it.

6)

Do

not

modify

the

power

cord

in

any

manner.

7)

Do

not

remove

screws

to

disassemble

the

unit

and

do

not

touch

anything

inside

the

unit.

8)

AC

power

cord

(For

U.S.A.

version

only)

The

AC

power

cord

of

this

unit

has

certain

one-way

direction

connections

to

prevent

electric

shock.

Refer

to

the

illustration

for

correct

connection.

.

(Fig.

1)

9)

Do

not

insert

any

metallic

objects

into

the

unit.

10)

Unplug

the

power

cord

when

there

is

a

possibility

of

lightning.

11)

If

water

gets

inside

the

unit,

unplug

the

power

cord

from

the

outlet

and

consult

your

dealer.

12)

Do

not

block

the

ventilation

holes

of

the

unit

so

that

heat

can

escape.

Do

not

install

the

unit

in

a

badly

ventilated

place.

13)

Be

sure

to

unplug

the

power

cord

from

the

outlet

when

going

out

or

when

the

unit

is

not

in

use

for

an

extended

period

of

time.

D-D-R-P

DYNAMICS

DETECTION

RECORDING

PROCESSOR

This

product

can

be

combinated

with

a

DDRP

(DYNAMICS

DETECTION

RECORDING

PROCESSOR)

system

(compact

disc

player

+

cassette

deck,

etc.)

to

enable

setting

the

optimum

recording

level

automatically.

Refer

to

these

instructions

for

details.