Küppersbusch IKDEM 976.1GE Quick setup guide

Other Küppersbusch Ventilation Hood manuals

Küppersbusch

Küppersbusch KD6250.0 Quick setup guide

Küppersbusch

Küppersbusch LB 632.0 WG Manual

Küppersbusch

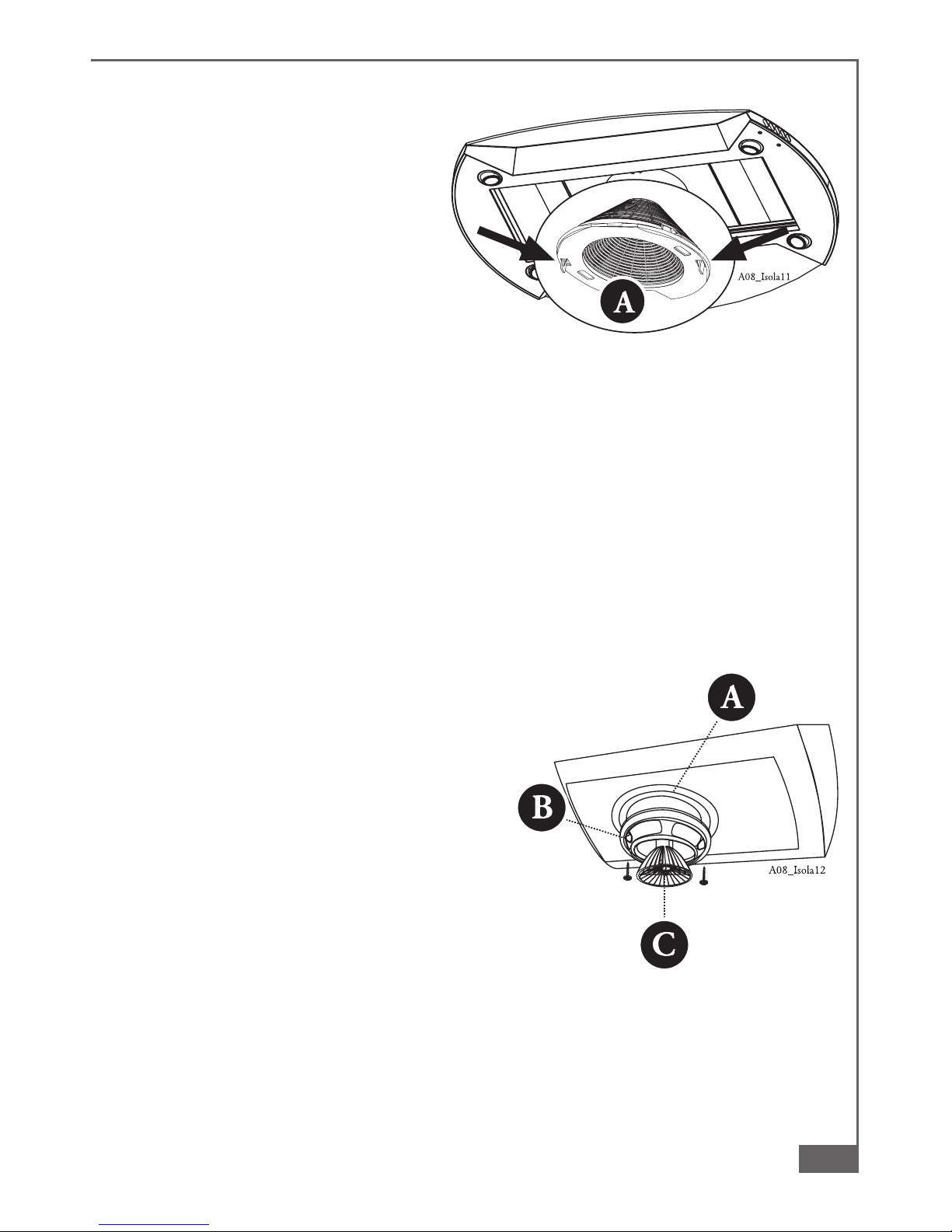

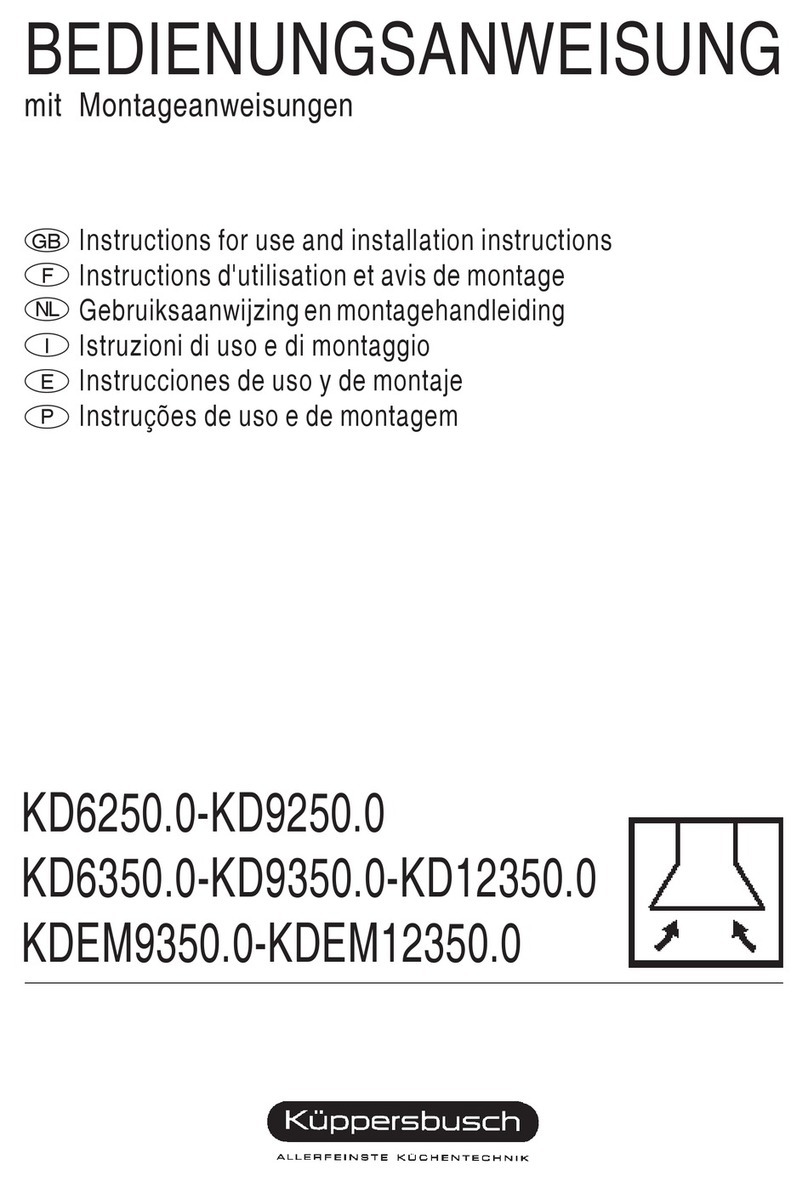

Küppersbusch DX ISLA User manual

Küppersbusch

Küppersbusch EDIP 6650.0 User manual

Küppersbusch

Küppersbusch EMI 850.0E User manual

Küppersbusch

Küppersbusch IKD 9210.1 GE Operation manual

Küppersbusch

Küppersbusch EMA 800.0W User manual

Küppersbusch

Küppersbusch Hood User manual

Küppersbusch

Küppersbusch IKD9885.0 Operator's manual

Küppersbusch

Küppersbusch D633.1 Quick setup guide

Küppersbusch

Küppersbusch IKD9890.0 Quick setup guide

Küppersbusch

Küppersbusch IKD 908.1 Quick setup guide

Küppersbusch

Küppersbusch 55 cm User manual

Küppersbusch

Küppersbusch IKD 937.0 GE User manual

Küppersbusch

Küppersbusch KD.. 9700.0GE User manual

Küppersbusch

Küppersbusch KD 9550 User manual

Küppersbusch

Küppersbusch KD 9850.0 Technical manual

Küppersbusch

Küppersbusch IKD3850.0E Operator's manual

Küppersbusch

Küppersbusch KD 6600 User manual

Küppersbusch

Küppersbusch IKD9880.0 Quick setup guide

Popular Ventilation Hood manuals by other brands

Gorenje

Gorenje S3 IHGC963S4X manual

KOBE

KOBE ISX2136SQB-1 Installation instructions and operation manual

U.S. Products

U.S. Products ADVANTAGE-100H Information & operating instructions

Kuppersberg

Kuppersberg DUDL 4 LX Technical Passport

Framtid

Framtid HW280 manual

Thermador

Thermador HGEW 36 FS installation manual