9

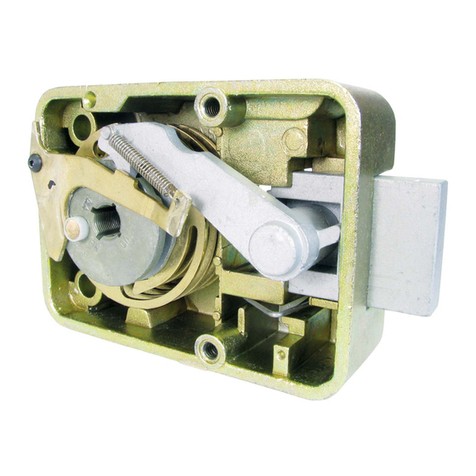

The axis of rotation of the handle is level

with the bottom lip of the strike.

B-2 Align the template along the vertical

center line of the mortise (CL) at the

desired handle height, and tape it to

the door.

B-3 Mark all holes and cutouts for the

mortise in the edge of the door and

remove the template.

B-4 Locate the two sets of vertical fold

lines on the template allowing you

toadjustthepositioningofthetem-

plate depending on the bevel of the

door.

Note: Fold lines on template are for

13⁄4” door. Some thickness and bevel

conditions may make it necessary to

re-position the template for marking

each side of the door.

B-5 If the door has no bevel, fold the template along the solid lines. Align the

fold with the edge of the door and mark the holes for the lock. Repeat on

the other side of the door. If the door has a 3° bevel, fold and align the

dashed line marked “H” on the template with the higher-beveled edge of

the door and mark the lock holes on that side of the door. Repeat on the

side with the lower-beveled edge using the dashed line marked “L.”

B-6 Prepare the cutout for the mortise in the edge of the door using a mortis-

ing machine, router and chisel (for dimensions, refer to template). Ensure

clearance is provided for moving latch parts as

indicated on the template.

B-7 When making holes, drill from both sides of the

door to prevent unsightly damage (for dimensions,

refer to template). Drill the small holes before the

large holes. This will keep small holes on location

before the 21⁄8“holes are made tangent with them.

Mortise

RH/LHR (ASM shown) LH/RHR

Handle

Height

LIT1051_Simplex_506x _Mortise_1012.indd 9 1/7/13 3:13 PM