Wir freuen uns, dass Sie sich für ein Klauke

Werkzeug entschieden haben und wünschen Ih-

nen viel Freude damit.

Sie haben ein Qualitätsprodukt „Made in

Germany“ erworben und erhalten 2 Jahre

Garantie. Diese beginnt mit dem Kaufbe-

legdatum.

Um lange Freude und eine einwandfreie Funk-

tion des Werkzeuges sicherzustellen, muss das

Gerät spätestens beim Erreichen von 10.000

Arbeitsvorgängen oder nach 3 Jahren durch

ein Autorisiertes Service Center (ASC) gewartet

werden. Wird das Wartungsintervall von 10.000

Arbeitsvorgängen nicht eingehalten, erlischt der

Garantieanspruch.

Im Rahmen dieser Wartung werden verschlis-

sene Teile ersetzt und sicherheitsrelevante Teile

geprüft und ggf. vorbeugend ersetzt.

Darüber hinaus empfehlen wir das Gerät jährlich

zur Überprüfung an das zuständige ASC einzu-

senden.

Für Fragen rund um unseren Werkzeugservice

oder eine Frage zu einem bestimmten Anwen-

dungsfall stehen wir Ihnen persönlich unter der

kostenlosen 0800-4685528 zur Verfügung.

Ihr Klauke Team

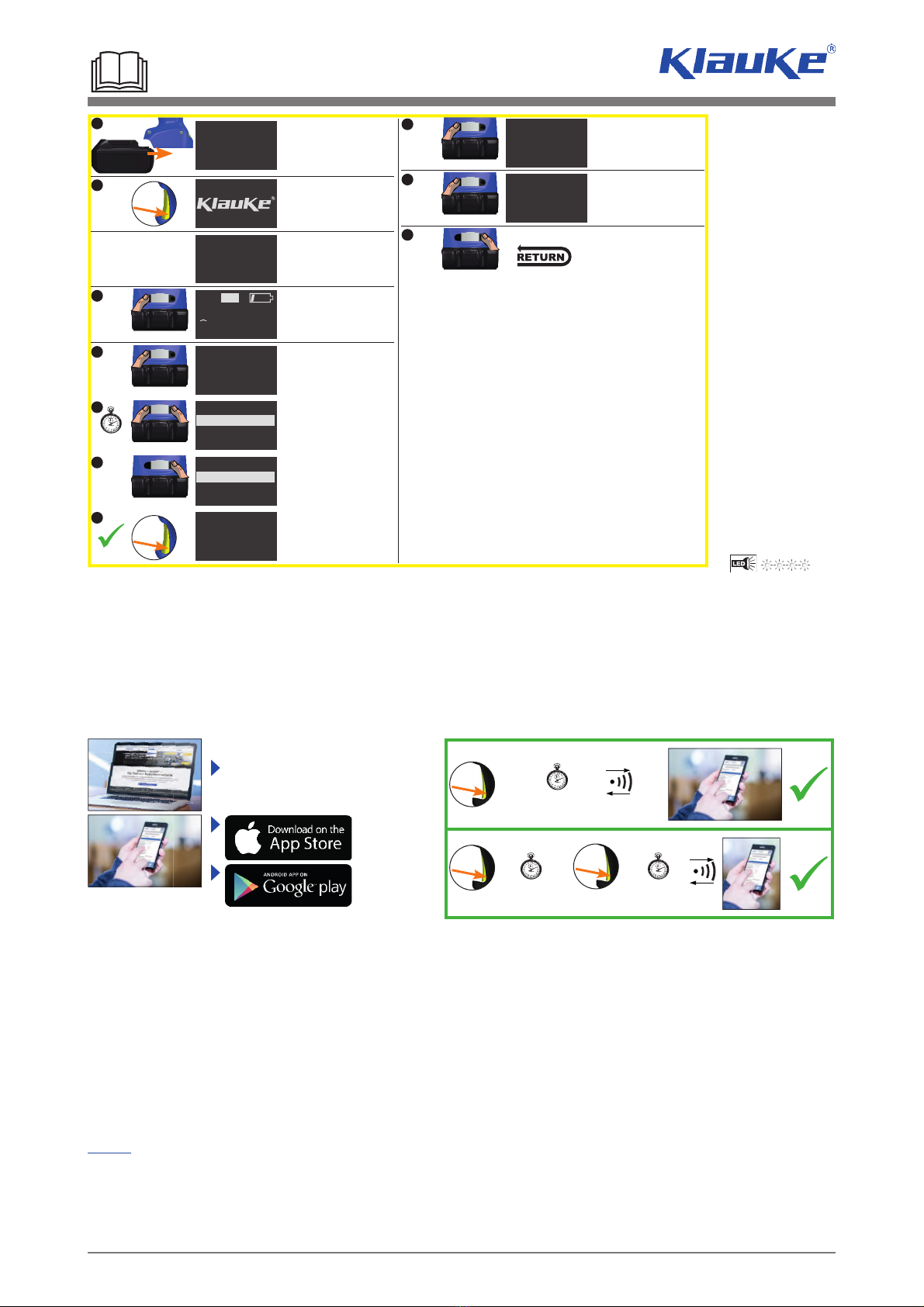

Thank you for choosing a Klauke tool. We hope

it gives you lots of pleasure.

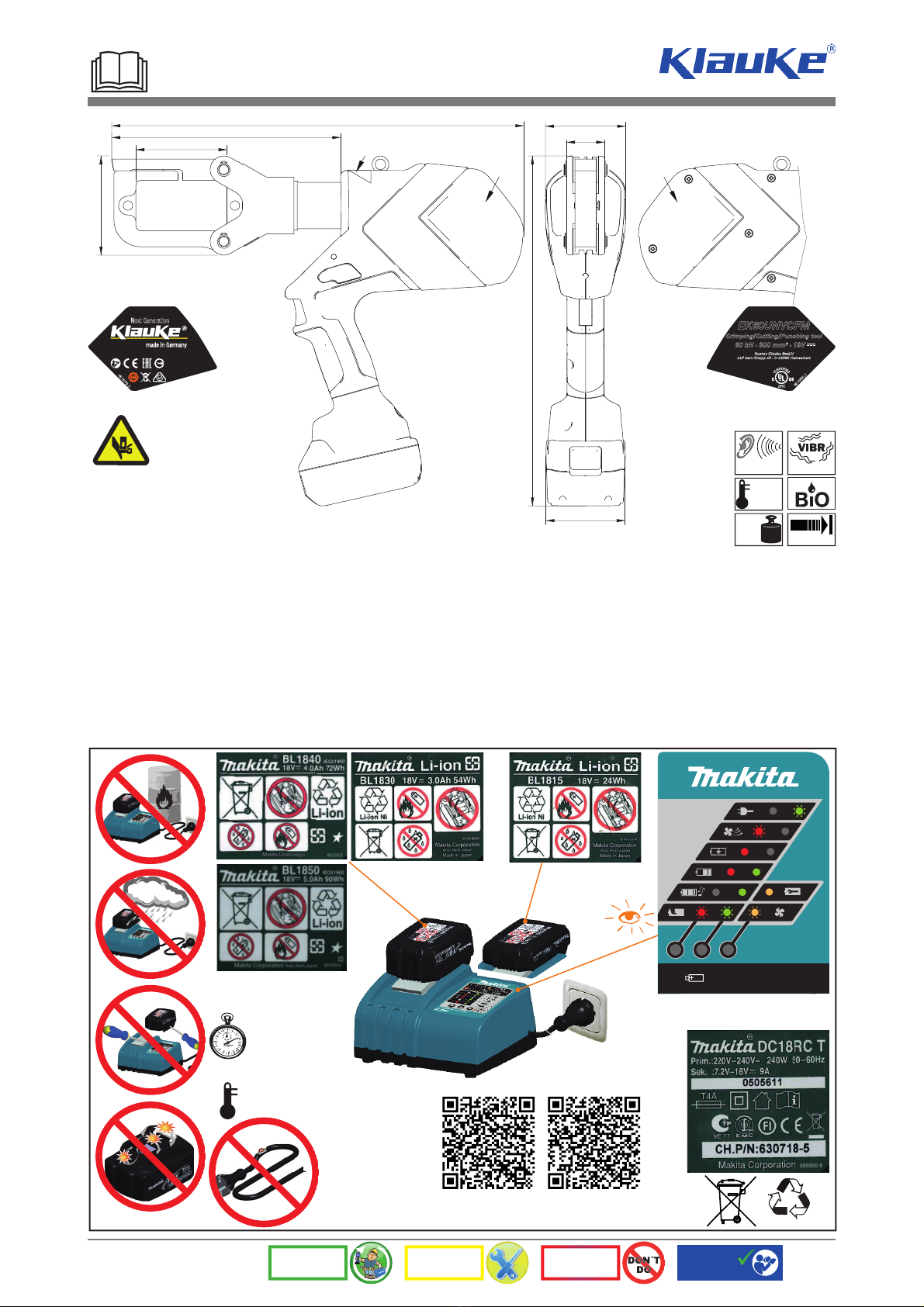

You have purchased a quality product

„Made in Germany“, which is covered by

a 2 year warranty. The warranty commen-

ces from the purchase receipt date.

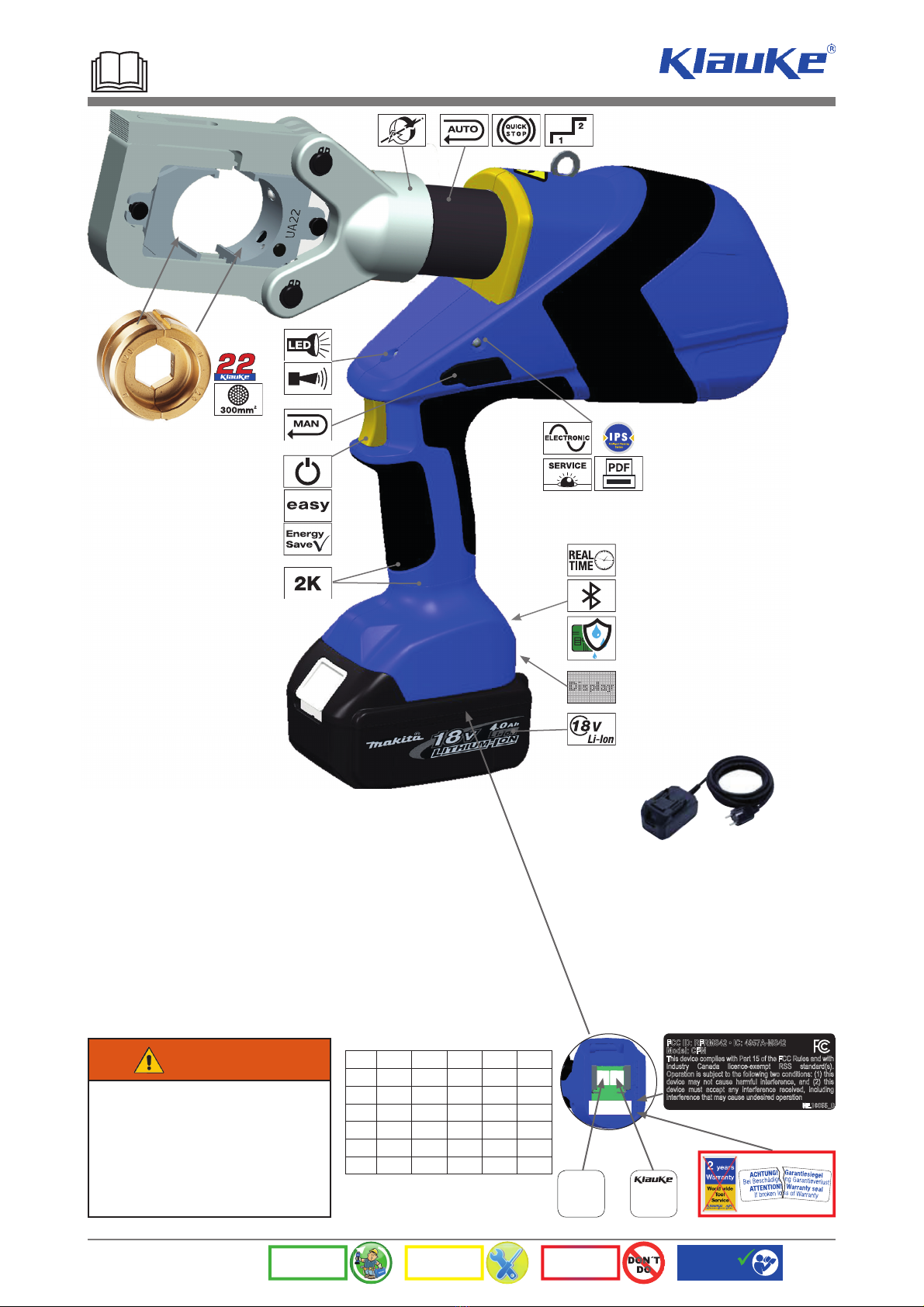

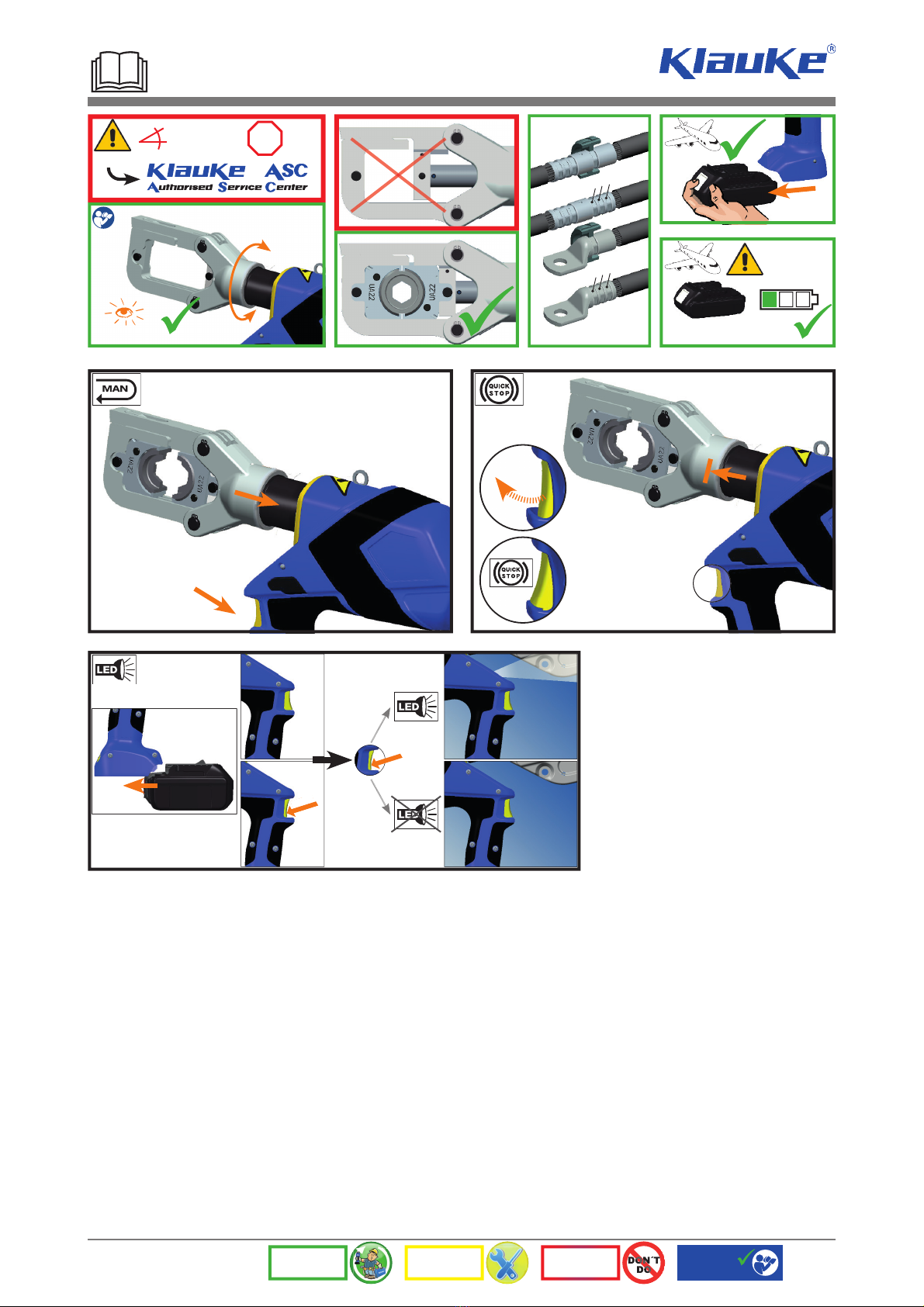

To ensure lasting enjoyment and a fl awless tool

function, the product must be serviced by an Au-

thorised Service Center (ASC) after 10,000 ope-

rations or after 3 years. Should the service Interval

exceed 10.000 cycles the warranty claim is void.

The Service includes predictive maintenance in

which worn-out parts will be replaced and safety

relevant parts checked/replaced.

We recommend to have the tools checked year-

ly through an Authorized Service Center (ASC).

If you have any questions about our tool service

or about a specifi c application, please go to

http://www.klauke.com/en/support/tool-service/

Your Klauke team