Antenna Telescope Installation Instructions

4ANTENNA®TELESCOPE™

©2021 Knoll Inc.

Using the Antenna®Telescope™

Installation Instructions and Parts Manual

An Overview

Each section of the Installation Instructions

and Parts Manual contains information to

guide you through Antenna®Telescope™

installations and to help you determine which

parts you may need to order as replacements

or to supplement reconfigurations.

Each page contains the

following sections:

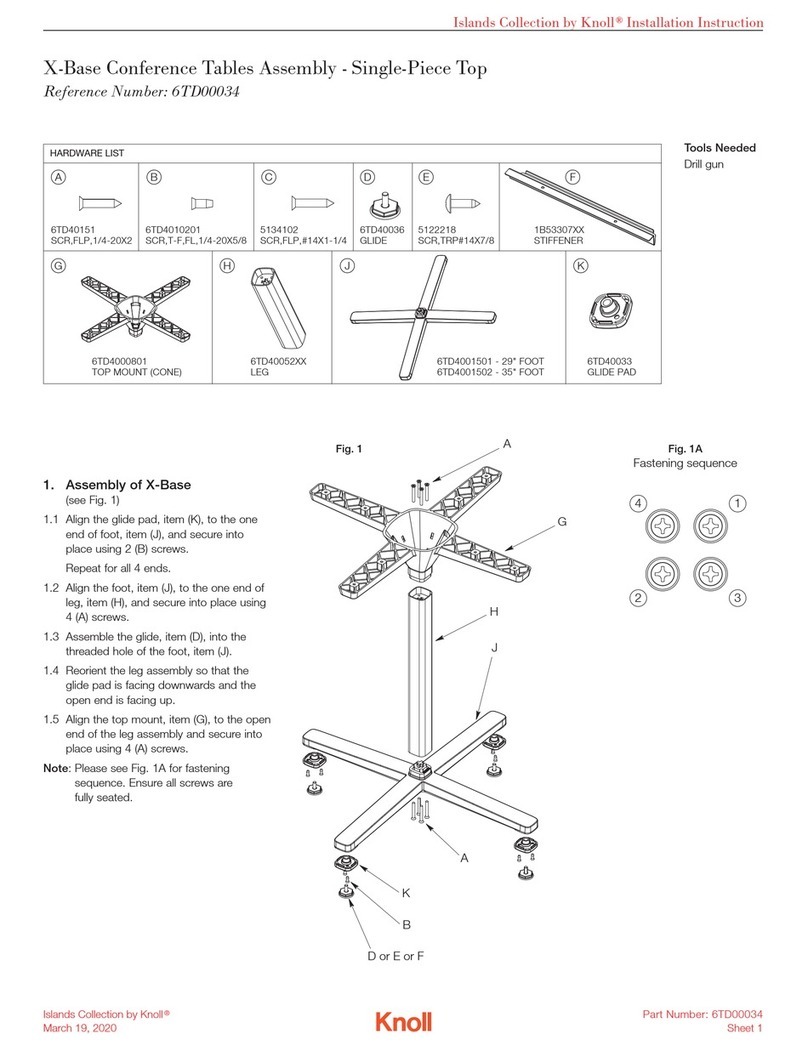

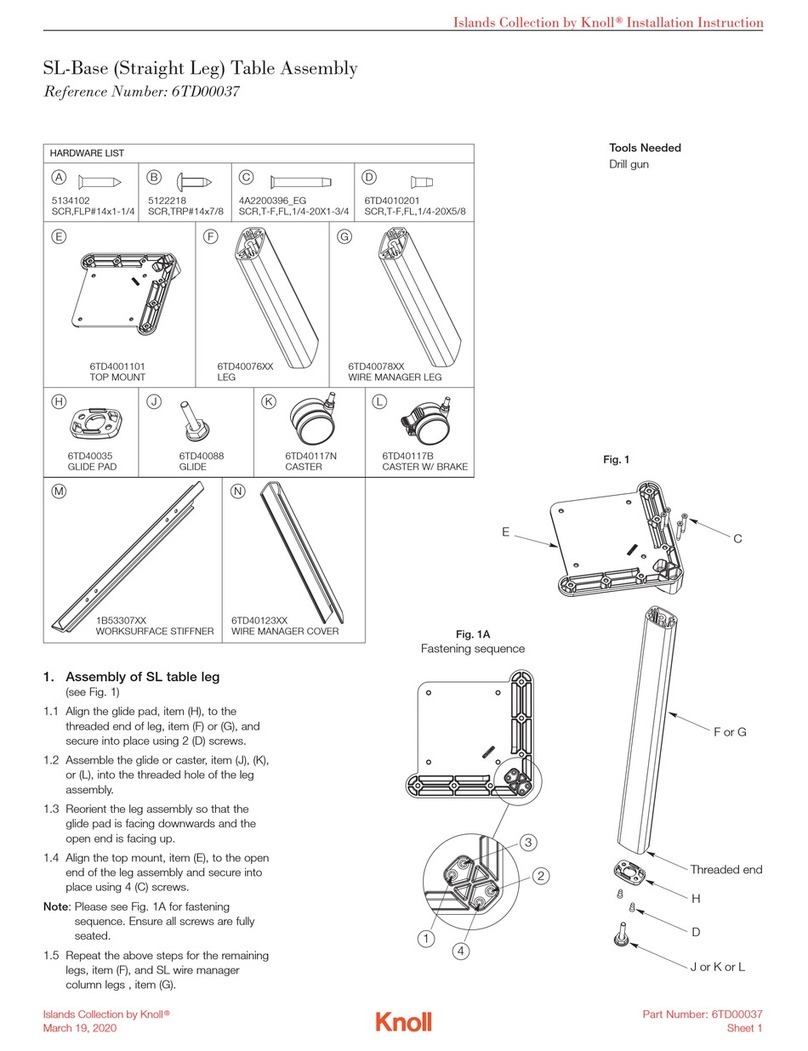

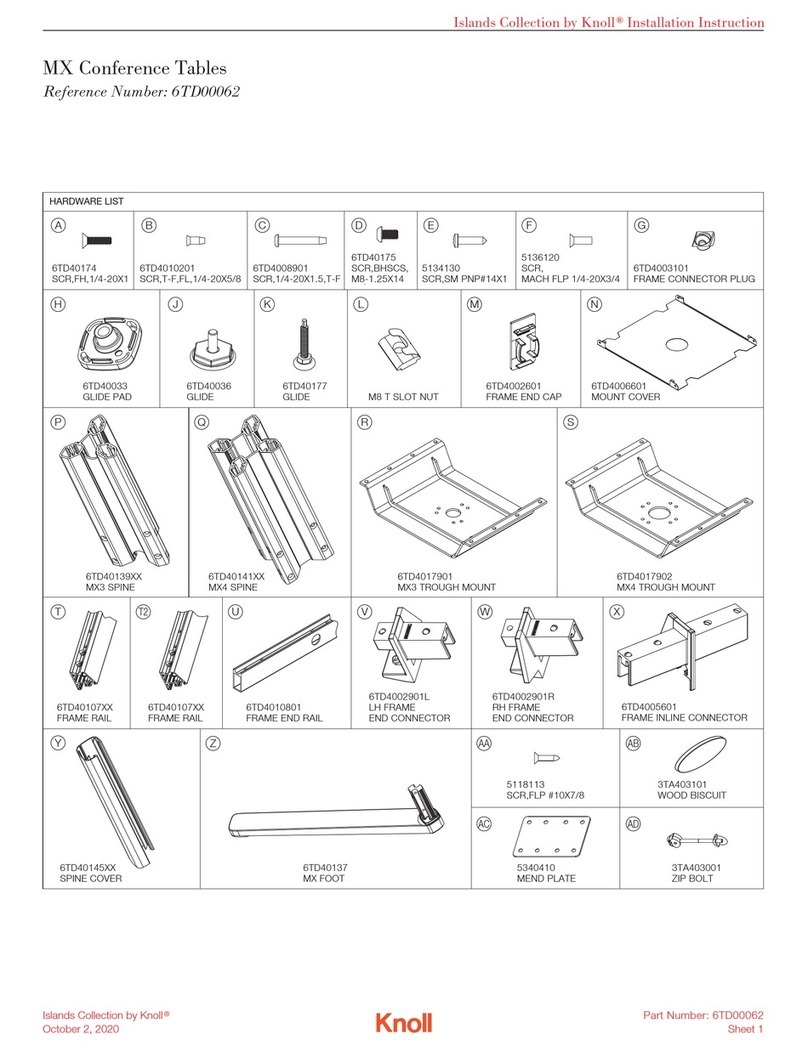

The Parts List section contains a lettered

list of the essential component parts

required for the application’s installation.

Items required that may vary in size, (i.e.

worksurfaces or rails), have not been lettered,

and replacements should be ordered

directly from the Price List or by contacting

Field Services for the correct part.

The Tools Needed section contains

a list of the installation tools that will be

required on site for the proper installation

of the application or configuration.

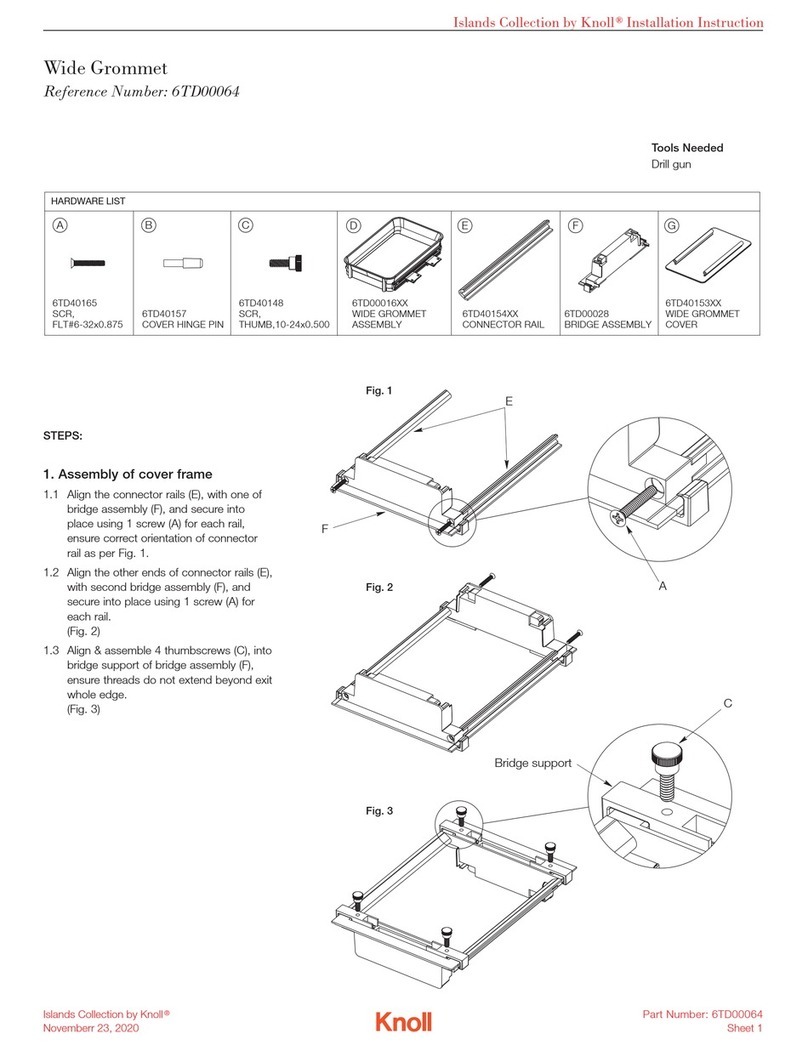

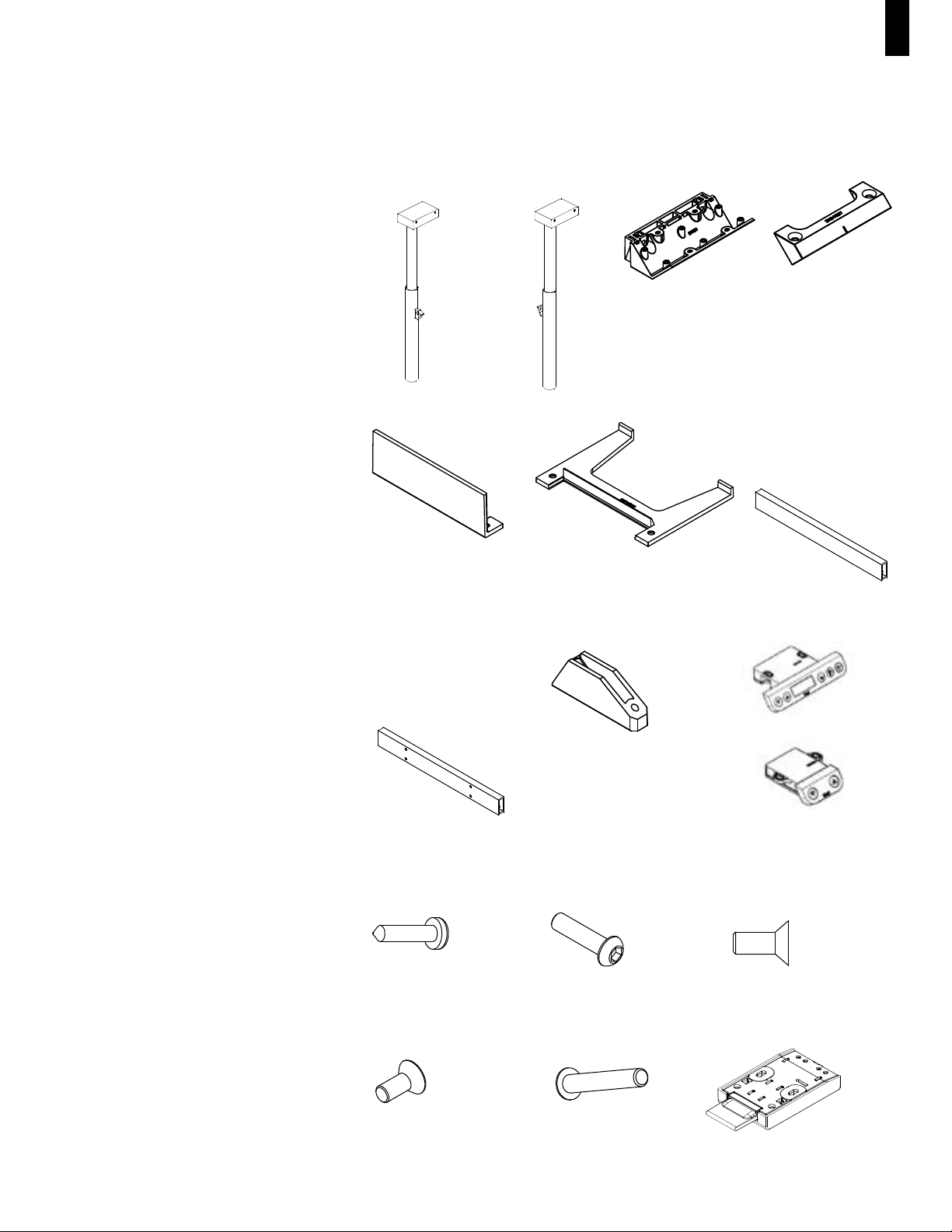

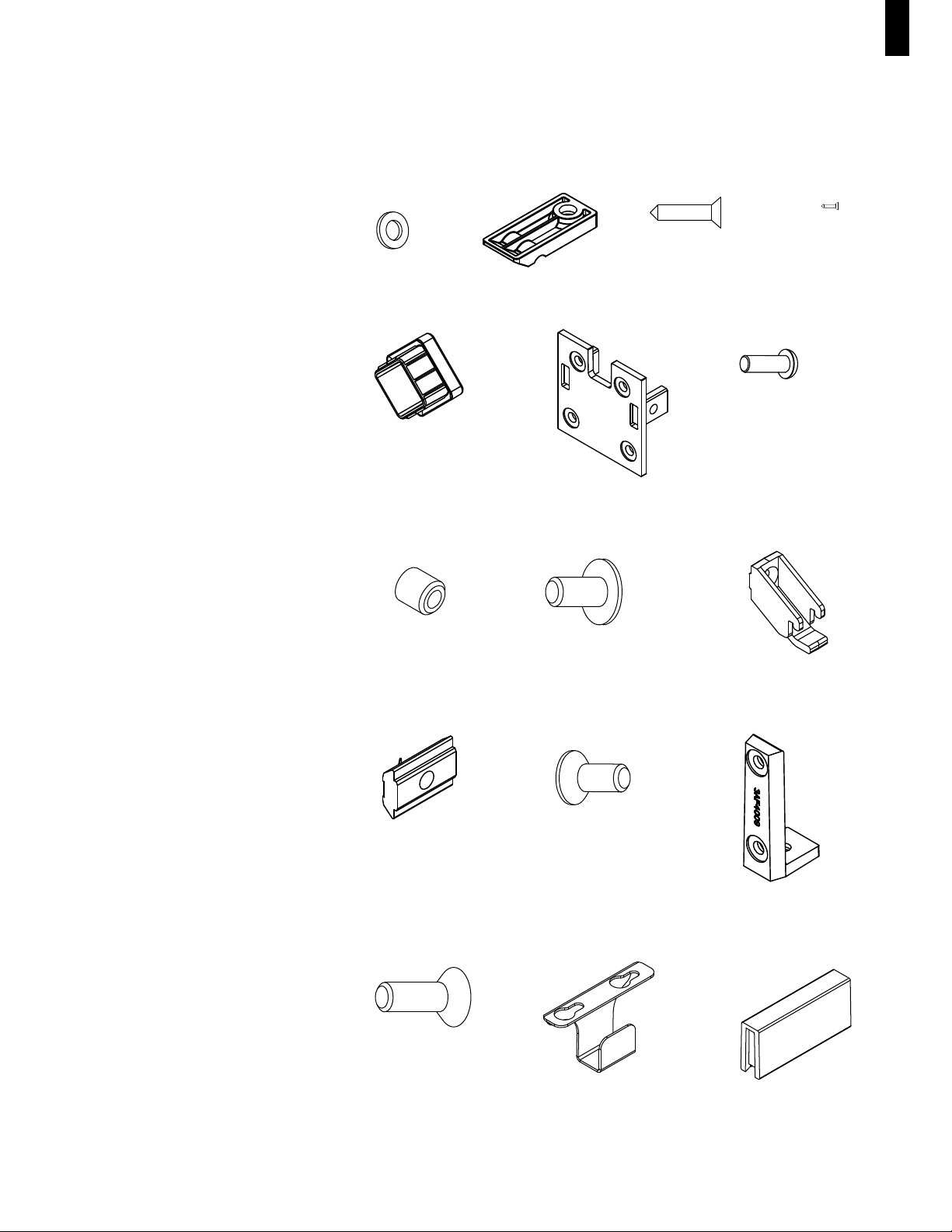

A Graphic Section has been included,

to the right of the Parts List, depicting

images of the component parts with

lettered codes that correspond to those

in the Parts List. Each part is shown with

its associated part number above.

NOTE: Part numbers with an asterisk, i.e.

*, after the number require a paint finish

code to be added to the end of the pattern

number to be orderable as a replacement

part. Please refer to the Finish Code listing at

the end of this page for the available codes.

NOTE: Part numbers with empty brackets,

i.e. (_), after the pattern number indicate

that a laminate or veneer finish code must

be added to the end of the pattern number

to be orderable as a replacement part.

Please refer to the Finish Code listing in the

Antenna™ Workspaces Price List for the

available finish codes for those products.

Please note that not all parts are

available in all finishes. Finish options

available for component parts match

those available when ordered with the

complete items’ pattern number per the

Antenna™ Workspaces Price List.

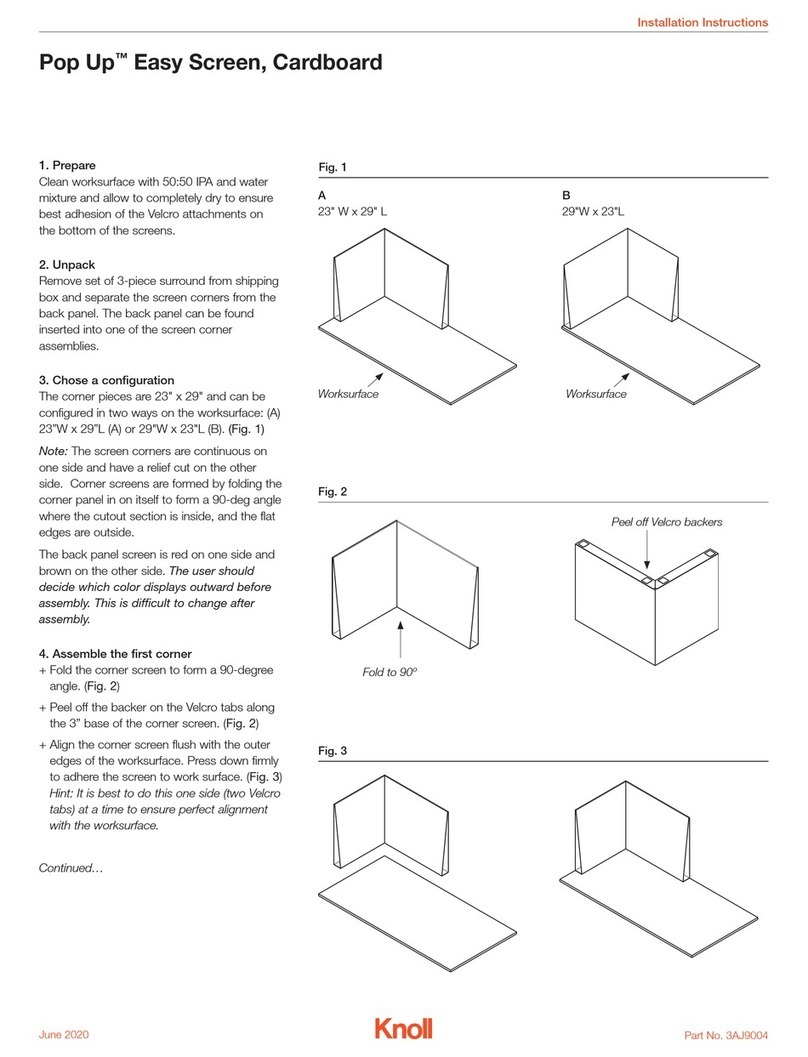

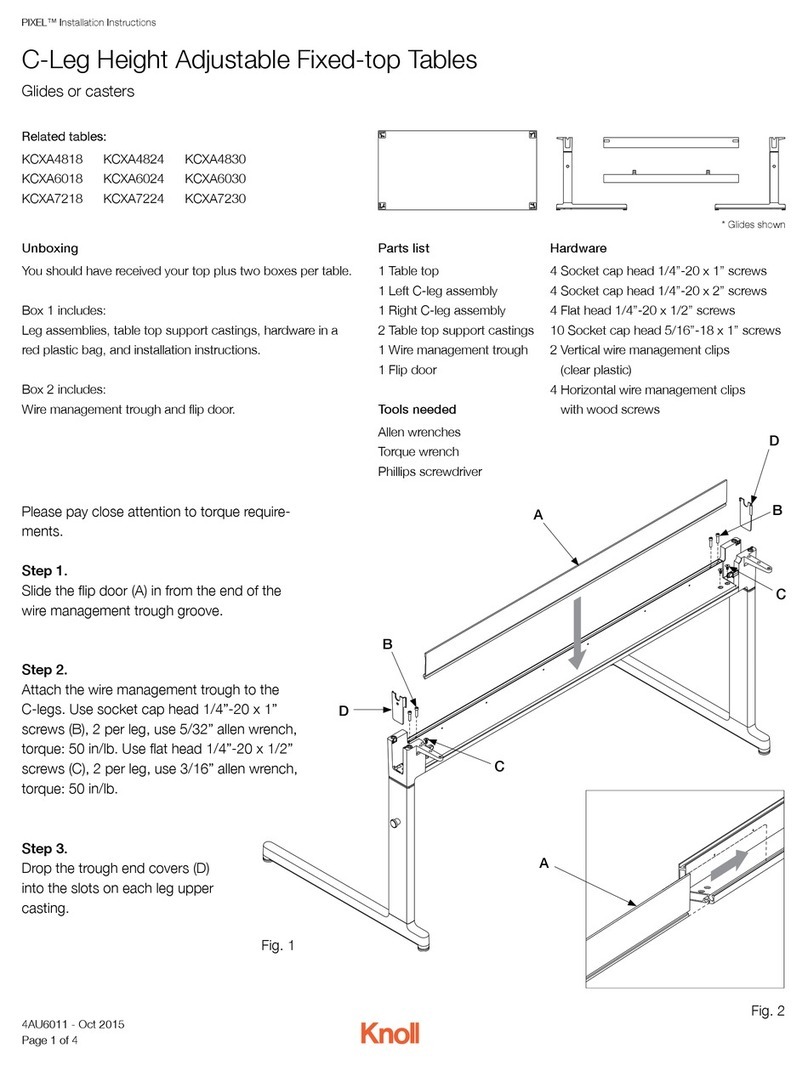

The Steps section details step-by-

step instructions for the installation of

the application selected. Each step

includes references to the lettered items

noted in the Parts List at the top of the

page and in the graphic section.

A Drawings section follows the steps

section providing detailed assembled

and exploded drawings to further

assist in installation and in determining

replacement parts required.

How to Order Parts

1. Look in this document’s bookmarks

to locate the configuration which

best fits the application.

2. Go to the page where that application

is described and thoroughly review all

installation instructions to determine

the part number(s) needed.

3. Unless otherwise noted, the standard

package quantity is one (1). When

ordering products where the quantity

per package is listed, please indicate

the number of packages required in

the quantity column of your order.

4. Be sure to add "KR" to the

beginning of each part number.

5. Be sure to include any finish

codes required to complete

the pattern number(s).

6. Complete a Knoll Service order,

which can be sent to your Knoll

Customer Service Representative.

If you have any questions about the

contents of this manual, please call

your Customer Service Representative

or Field Service at 800-343-5665.

Paint Finish Codes:

111T - Jet Black

112T - Brown

113T - Dark Grey

114T - Folkstone Grey

115T - Medium Grey

116T - Sandstone

117T - Soft Grey

118T - Bright White

611T - Beige Metallic Mist

612T - Medium Metallic Grey

613T - Silver

130T - Dark Red

131T - Slate Blue

Introduction